Anti-ultraviolet PVC film and preparation method thereof

An anti-ultraviolet and ultraviolet technology, applied in the field of outer packaging film, can solve the problems that PVC film does not have anti-UV, cumbersome preparation method, low work efficiency, etc., and achieves the effects of improving thermal stability, delaying oxidation process and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

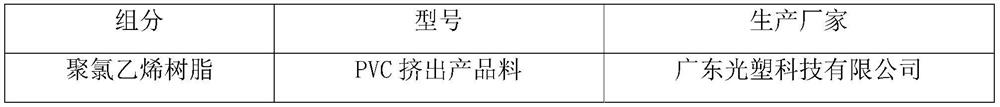

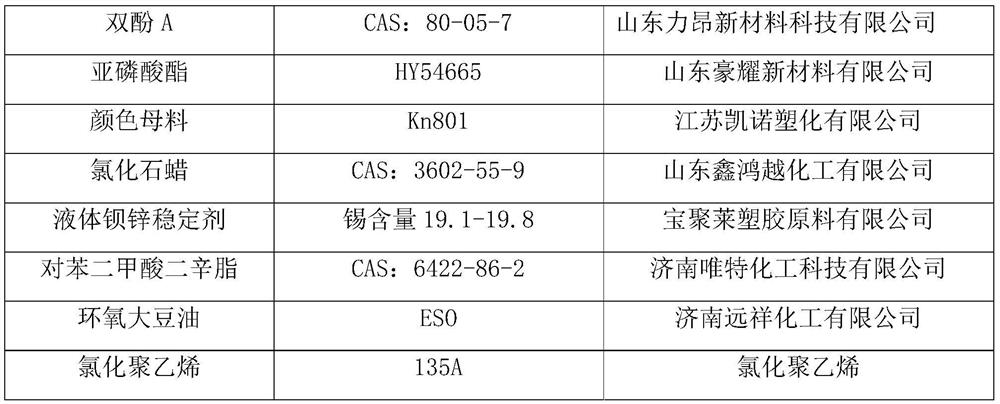

[0033] Embodiment 1: As shown in Table 2, a kind of anti-ultraviolet PVC film, its constituent material comprises: 95 parts of polyvinyl chloride resin, 1.5 parts of bisphenol A, 0.2 part of ultraviolet absorber, 1 part of color masterbatch, 0.4 part of chlorine Chemical paraffin, 0.5 parts of liquid barium zinc stabilizer, 25 parts of dioctyl terephthalate, 3 parts of epoxy soybean oil, 2 parts of chlorinated polyethylene;

[0034] Wherein, the ultraviolet agent is made of 15 parts of modified nano-titanium dioxide, 45 parts of phase transfer agent, and 10 parts of sodium octadecyl methanesulfonate.

[0035] According to above raw material, a kind of preparation method of anti-ultraviolet PVC film comprises the following steps:

[0036] S1: Add polyvinyl chloride resin, bisphenol A, ultraviolet absorber, color masterbatch, chlorinated paraffin in the water phase pot in sequence and heat to 90°C, keep stirring at 600r / min for 4min to obtain powdery material;

[0037] S2: Add ...

Embodiment 2

[0044] Example 2: As shown in Table 2, the difference from Example 1 is: an anti-ultraviolet PVC film, and its constituent materials, 1.5 parts of bisphenol A are replaced by 1.5 parts of phosphite.

[0045] According to above raw material, a kind of preparation method of anti-ultraviolet PVC film comprises the following steps:

[0046] S1: Add polyvinyl chloride resin, bisphenol A, ultraviolet absorber, color masterbatch, and chlorinated paraffin in the water phase pot in sequence and heat to 100°C, keep stirring at 500r / min for 5min to obtain a powdery material;

[0047] S2: Add stabilizer, plasticizer, and chemically modified oil into the emulsification pot, heat to 90°C, keep stirring at 1200r / min for 5min, and obtain liquid material;

[0048] S3: Put the powdery material and liquid material into the mixing pot, heat the mixing pot to 100°C, keep stirring at 1300r / min for 2min, add chlorinated polyethylene into the mixing pot, stir and dissolve; then put it into the cold mix...

Embodiment 3

[0054] Embodiment 3: As shown in Table 2, the difference from Embodiment 1 is: an anti-ultraviolet PVC film, and its constituent materials include: 90 parts of polyvinyl chloride resin, 0.7 part of bisphenol A, 0.1 part of ultraviolet absorber , 2 parts of color masterbatch, 1 part of chlorinated paraffin, 1 part of liquid barium zinc stabilizer, 20 parts of dioctyl terephthalate, 3 parts of epoxy soybean oil, 1.5 parts of chlorinated polyethylene;

[0055] Wherein, the ultraviolet absorber is made of 20 parts of modified nano-titanium dioxide, 60 parts of phase transfer agent, and 5 parts of sodium octadecyl methylsulfonate.

[0056] According to above raw material, a kind of preparation method of anti-ultraviolet PVC film comprises the following steps:

[0057] S1: Add polyvinyl chloride resin, bisphenol A, ultraviolet absorber, color masterbatch, and chlorinated paraffin in the water phase pot in sequence and heat to 90°C, keep stirring at 700r / min for 2min to obtain powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com