Nano coating material composition and construction method thereof

A nano-coating and construction method technology, applied in the field of coatings, can solve the problems of easy agglomeration and peeling off, slow drying of nano-coatings, difficult dispersion of nano-coatings, etc., and achieves the effects of shortening drying time, accelerating drying speed and excellent quick-drying performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

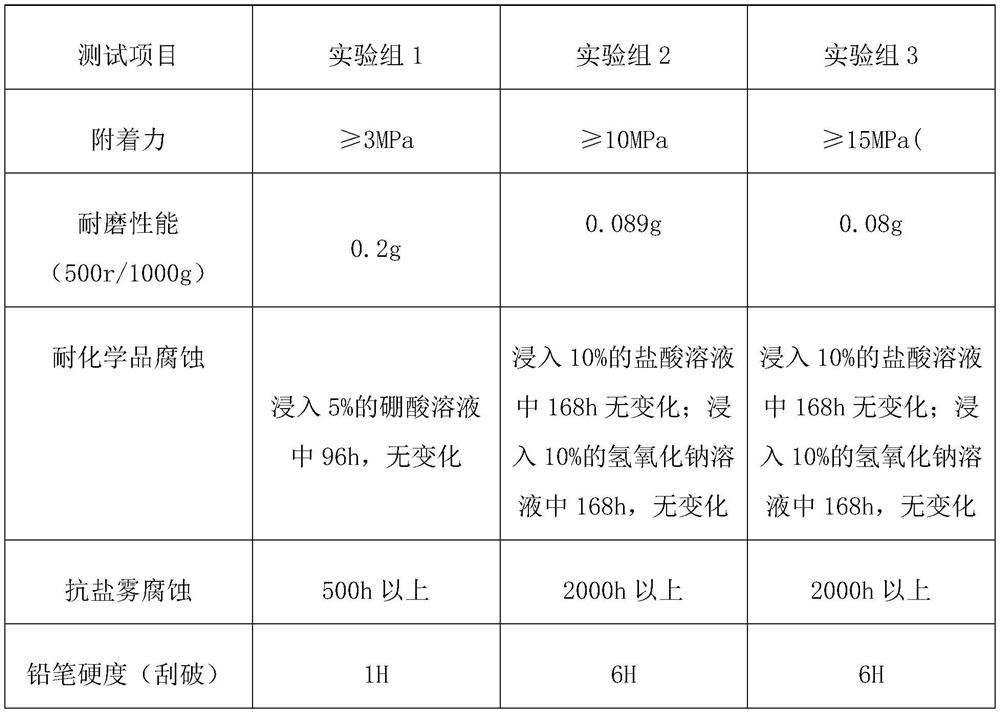

Embodiment 1

[0037]A nano-coating composition, wherein the coating is composed of a main base material, a curing agent and a diluent in a mass ratio of 8:2:1, and the main base material includes the following raw materials in mass fractions: acrylic resin 58%, titanium dioxide 20% %, 10% ethanol, 10% ethyl acetate, 1% inert nano material and 1% surfactant; the curing agent Wanhua W6875A, the diluent is industrial ethanol, and the inert nano material is titanium dioxide.

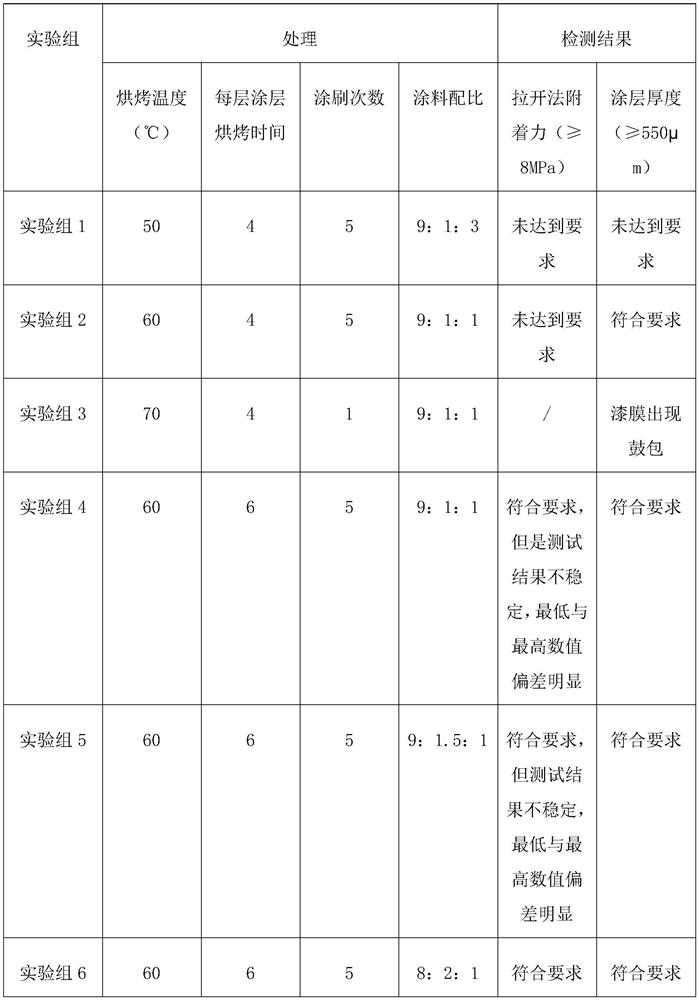

[0038] Above-mentioned nano coating composition is used for construction, and construction method is:

[0039] Substrate treatment: use an angle grinder to grind the surface of the substrate to St2.5, that is, there is no visible oil and dirt on the surface of the steel, and there are no attachments such as scale, rust, and paint coating that are not firmly attached; the exposed part of the substrate The surface has a metallic luster. Clean the substrate. Cleaning includes the following steps: 1) Dip the paint thinner wi...

Embodiment 2

[0045] A nano-coating composition, wherein the coating is composed of a main base material, a curing agent and a diluent in a mass ratio of 8:1.8:1.2, and the main base material includes the following raw materials in mass fractions: acrylic resin 63%, titanium dioxide 15% %, ethanol 10%, ethyl acetate 8%, inert nano material 3% and surfactant 1%; the curing agent Wanhua W6875A, the diluent is industrial ethanol, and the inert nano material is titanium dioxide.

[0046] Above-mentioned nano coating composition is used for construction, and construction method is:

[0047] Substrate treatment: use an angle grinder to grind the surface of the substrate to St2.5, that is, there should be no visible oil stains and dirt on the steel surface, and there should be no attachments such as oxide scales, rust and paint coatings that are not firmly attached. The surface of the exposed part of the substrate should have a metallic luster. Clean the substrate. Cleaning includes the following...

Embodiment 3

[0052] A nano-coating composition, wherein the coating is composed of a main base material, a curing agent and a diluent in a mass ratio of 8.2:2:1.1, and the main base material includes the following raw materials in mass fractions: acrylic resin 55%, titanium dioxide 25% %, ethanol 8%, ethyl acetate 9%, inert nanomaterials 1% and surfactant 2%; the curing agent Wanhua W6875A, the diluent is industrial ethanol, and the inert nanomaterials are titanium dioxide and titanium dioxide Silicon mixture.

[0053] Above-mentioned nano coating composition is used for construction, and construction method is:

[0054] Substrate treatment: use an angle grinder to grind the surface of the substrate to St2.5, that is, there should be no visible oil stains and dirt on the steel surface, and there should be no attachments such as oxide scales, rust and paint coatings that are not firmly attached. The surface of the exposed part of the substrate should have a metallic luster. Clean the subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap