High-strength Mg-Gd-Y-Zn-Zr rare-earth magnesium alloy and preparation method thereof

A technology of rare earth magnesium and magnesium alloys, which is applied in the deformation processing of non-ferrous metal materials and the field of metal materials, can solve the problems of reduced strength, poor mechanical properties, and difficult to be widely used in aerospace fields, and achieve high service temperature, high specific strength and specific strength. The effect of stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The high-strength Mg-Gd-Y-Zn-Zr rare earth magnesium alloy is formulated according to the following mass percentages: 12.0% Gd, 4.5% Y, 2.0% Zn, 0.4% Zr, and the balance is magnesium and unavoidable impurity elements , and prepared into magnesium alloy rods. The tensile strength and elongation of the obtained magnesium alloy rods were tested, and the specific test results are shown in Table 1.

[0043] Table 1 The mechanical property data obtained in the test of the magnesium alloy bar prepared in Example 1

[0044] Tensile strength (Rm) / MPa Yield strength (R p0.2 ) / MPa

[0045] The concrete preparation method of this alloy comprises the following steps:

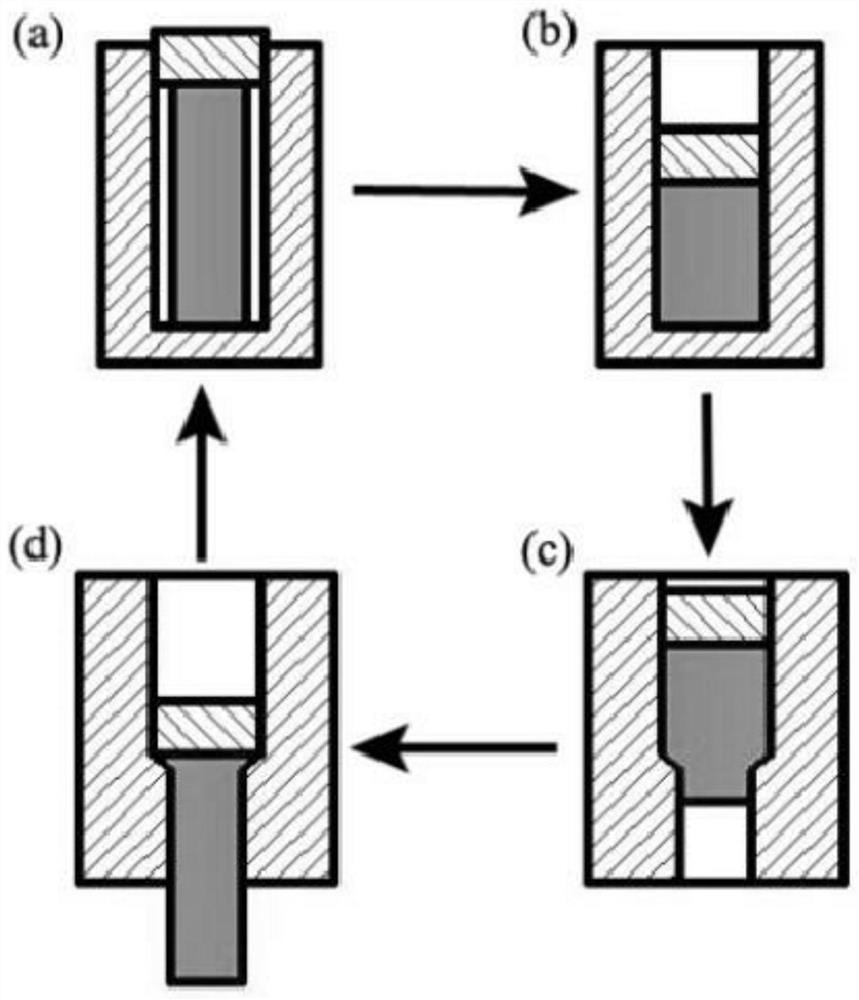

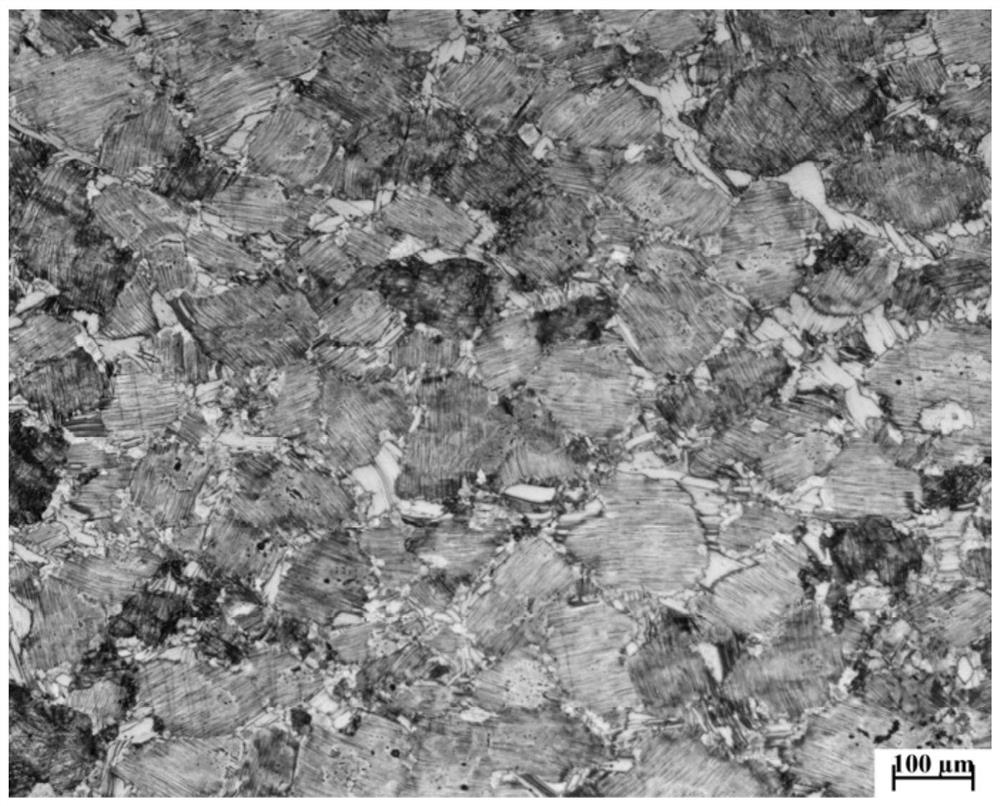

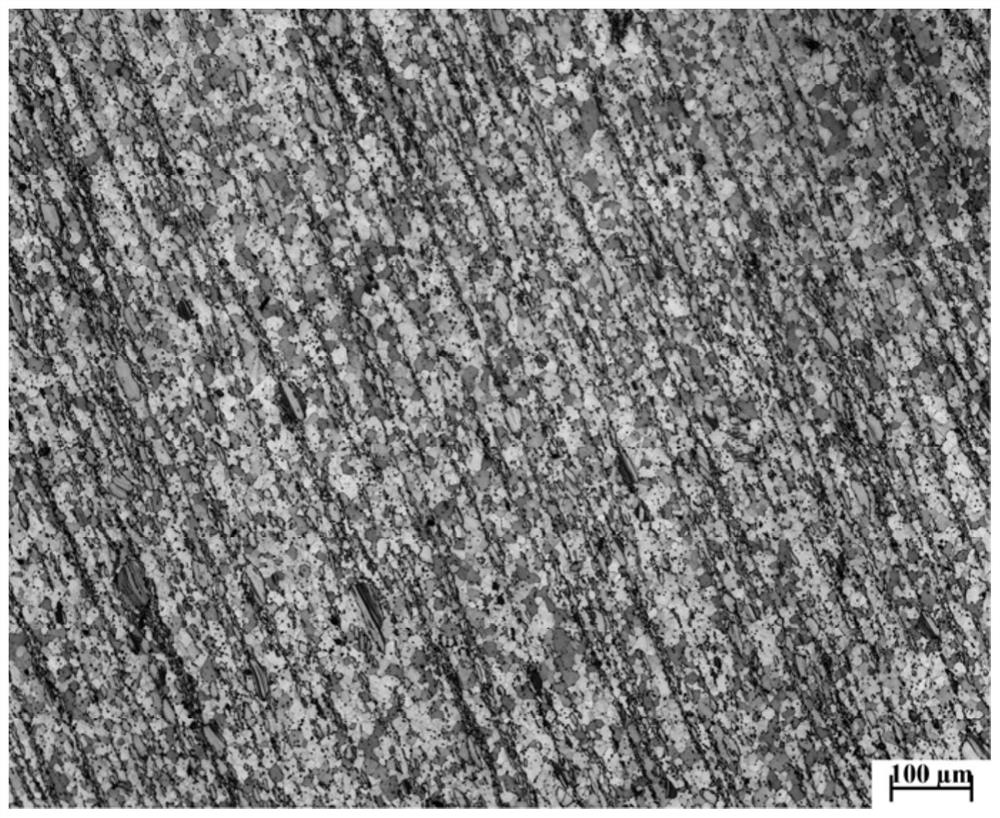

[0046] (1) Preparation of magnesium alloy cast rod: first design the alloy element proportioning material according to the above mass percentage, adopt semi-continuous casting to prepare a magnesium alloy cast rod of φ400×4200mm, and machine it into a rod stock of φ330mm after cooling at room temperat...

Embodiment 2

[0063] In this embodiment, the high-strength Mg-Gd-Y-Zn-Zr rare earth magnesium alloy is proportioned according to the following components by mass percentage: 11.0% Gd, 4.5% Y, 2.0% Zn, 0.6% Zr, and the balance is magnesium and Unavoidable impurity elements, the alloy is prepared by the same preparation method as in Example 1, specifically, it is prepared by semi-continuous casting according to (1.1)-(1.5) of step (1) in Example 1 to φ400×4200mm Then the magnesium alloy cast rod is heated up to 325°C, and after 4 hours of heat preservation, it is homogenized at 535°C for 9 hours; the homogenized cast rod is subjected to upsetting extrusion composite deformation: firstly, the cast rod is heated to 350°C, hold for 2 hours for primary heating, then heat the cast rod to 480°C, hold for 6 hours for secondary heating, and perform upsetting and extrusion composite deformation on the heated bar. The heating temperature of the mold is 410-450°C. The pressure ratio is 1.95:1, and the e...

Embodiment 3

[0065] In this embodiment, the high-strength Mg-Gd-Y-Zn-Zr rare earth magnesium alloy is proportioned according to the following components by mass percentage: 13.0% Gd, 4.0% Y, 2.0% Zn, 0.5% Zr, and the balance is magnesium and Unavoidable impurity elements, the alloy is prepared by the same preparation method as in Example 1, specifically, it is prepared by semi-continuous casting according to (1.1)-(1.5) of step (1) in Example 1 to φ400×4200mm Then the magnesium alloy cast rod is heated up to 325°C, and after 4 hours of heat preservation, it is homogenized at 535°C for 9 hours; the homogenized cast rod is subjected to upsetting extrusion composite deformation: firstly, the cast rod is heated to 350°C, hold for 2 hours for primary heating, then heat the cast rod to 480°C, hold for 6 hours for secondary heating, and perform upsetting and extrusion composite deformation on the heated bar. The heating temperature of the mold is 420-450°C, extrusion The pressure ratio is 1.95:1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com