Preparation method of high-count composite yarn

A composite yarn, high-count technology, applied in the direction of yarn, textiles and papermaking, can solve the problems of affecting the degree of fiber cohesion, spun silk fibers are prone to static electricity, easy to generate fuzz and entanglement, etc., to achieve stable and improved yarn quality. The effect of feeling bulky and high internal cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

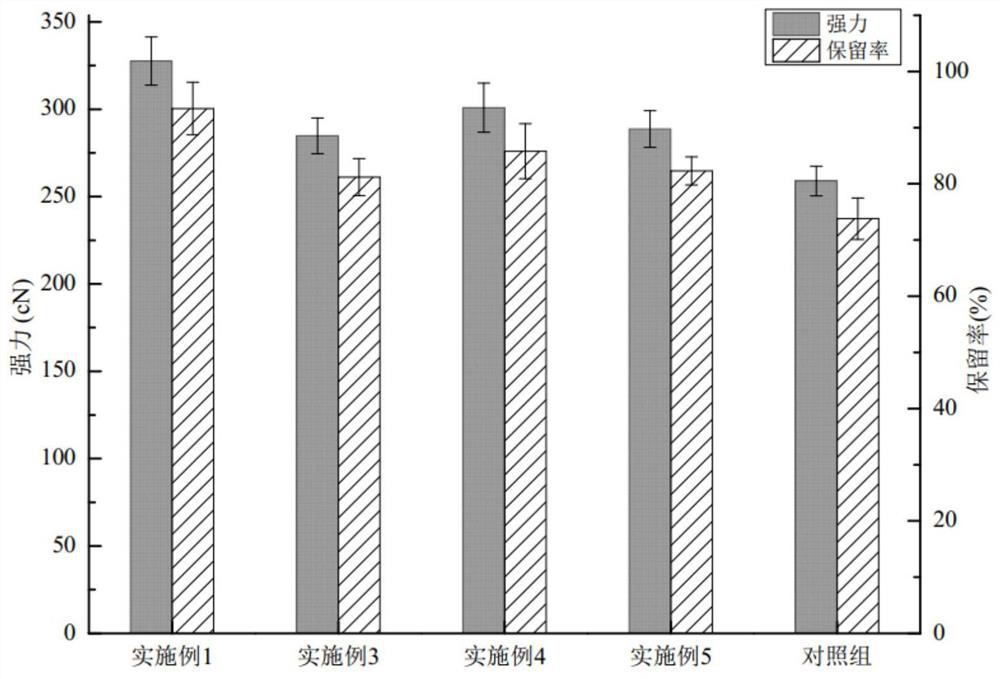

Embodiment 1

[0038] A preparation method of high-count composite yarn, the specific steps are as follows:

[0039] 1) choose respectively that count is 80S, average length is 25 parts by weight of 1# cashmere fiber of 45mm, count is 48S, average length is 15 parts by weight of 2# cashmere fiber of 80mm, to 1# and 2# cashmere fiber raw material respectively Add the wool treatment agent in the wool blending machine, and then mix it in the wool blending machine to obtain the wool wool fiber, then seal the above wool wool fiber, and place it in a humidification room with a temperature of 60°C and a relative humidity of 85% for 30 hours to make the fiber fully Absorb antistatic oil agent and moisture, finally obtain pretreatment 1# cashmere fiber and pretreatment 2# cashmere fiber; Above-mentioned and wool treatment agent comprise following raw materials by weight: 0.6 part of antistatic agent, 0.7 part of wool oil, 0.3 part of organic Silicone oil, 0.5 parts of penetrating agent JFC and 10 par...

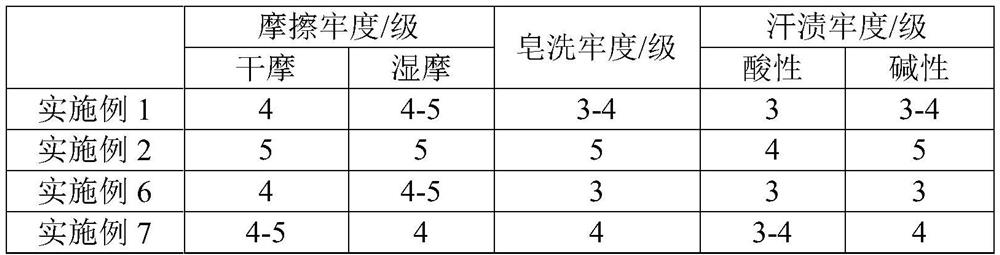

Embodiment 2

[0049] A kind of preparation method of high-count composite yarn, when working, the difference with embodiment 1 only lies in: in the pretreatment step of cashmere fiber, also comprise the o-nitrobenzoic acid of 0.05 weight part and 0.08 in the wool treatment agent Glycine in parts by weight.

Embodiment 3

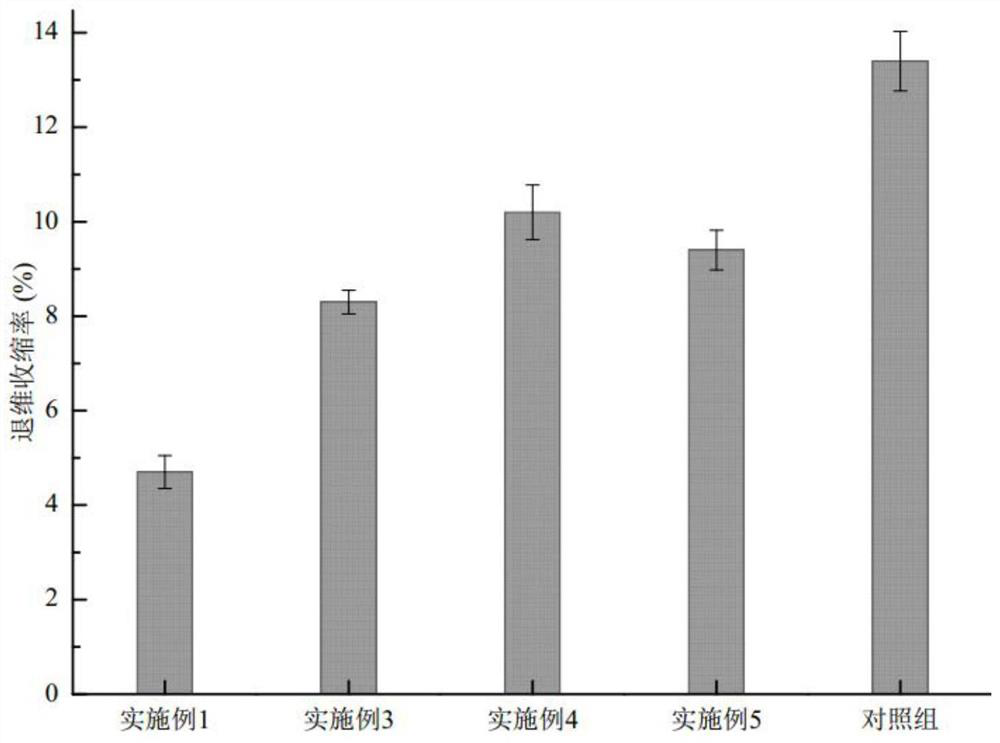

[0051] A method for preparing a high-count composite yarn, when working, differs from Example 1 only in that: in step 8), the dimension-removal treatment liquid includes: 2.5g / L penetrating agent DJ-1399, 5g / L of NaOH and 0.08g / L of diphenylphosphoric acid, the solvent is water; no d-quinic acid is added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com