A kind of preparation method and application of titanium dioxide/carbon/ferrous disulfide composite material

A technology of ferrous disulfide and composite materials, which is applied in the field of lithium-ion batteries and lithium-ion battery electrode materials, can solve the problems of electrical performance to be improved, and achieve the effects of low cost, high specific capacitance and high repetition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

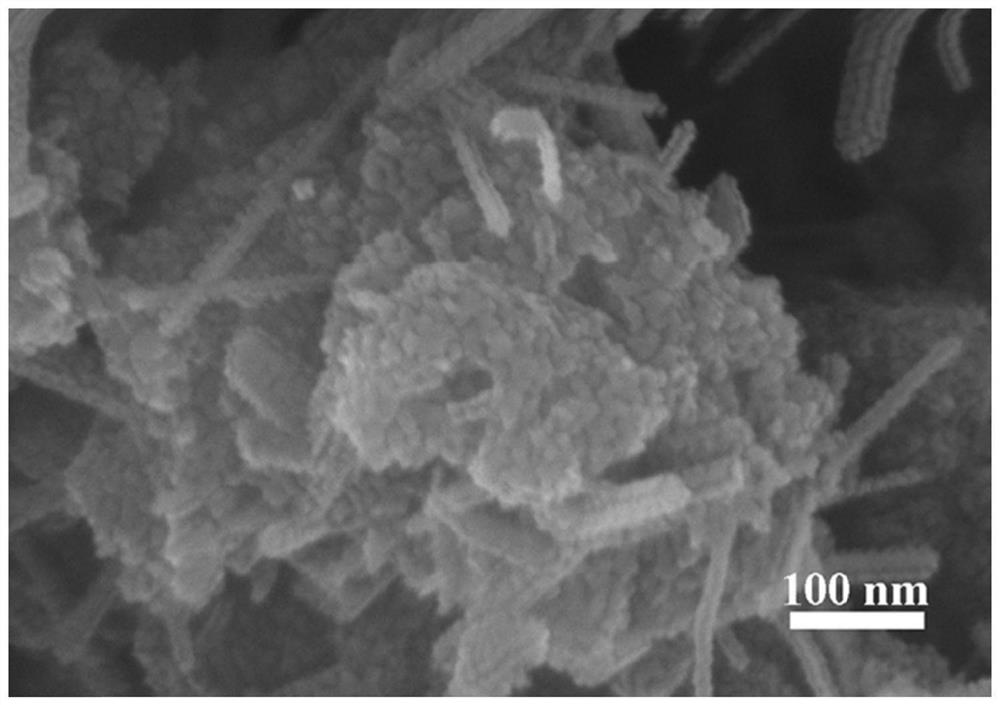

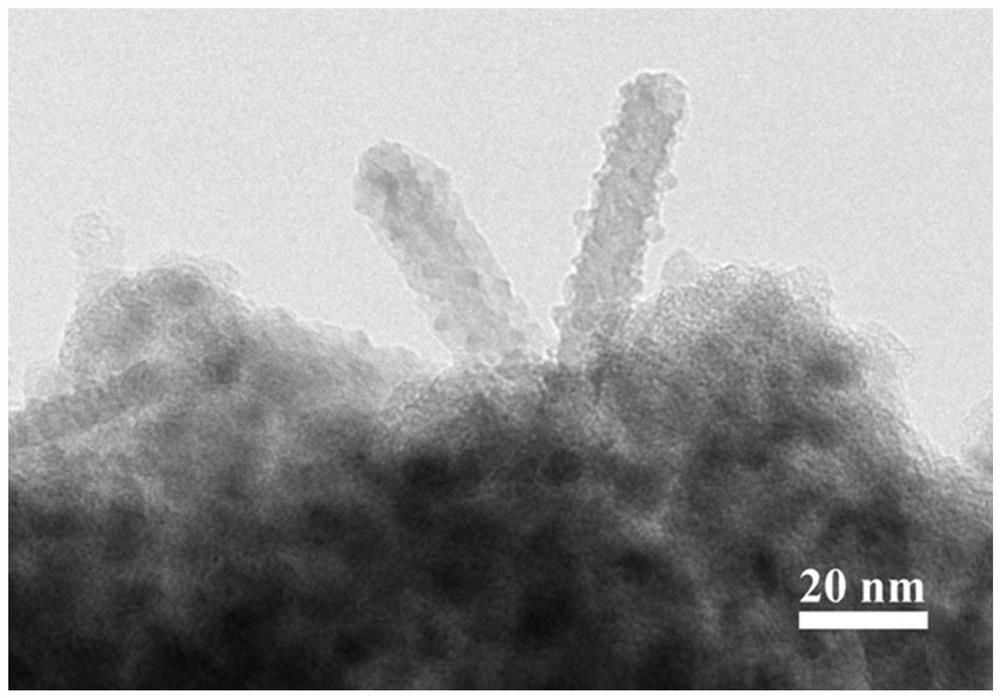

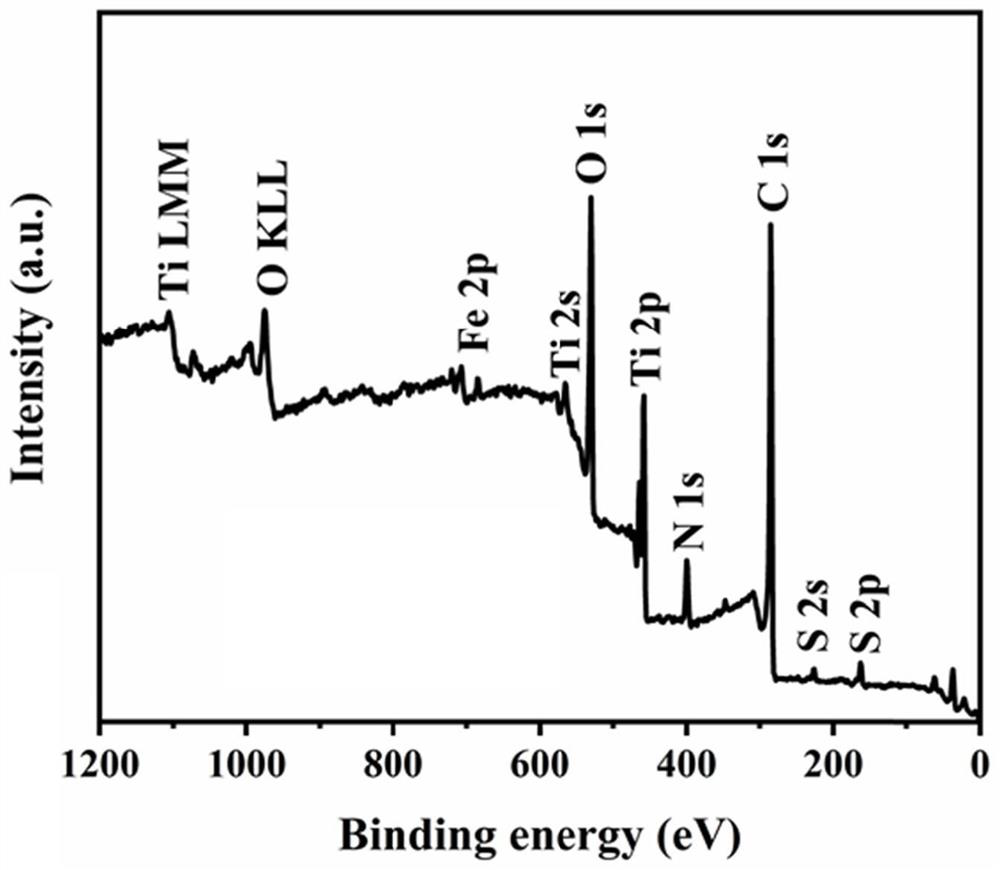

[0042] This embodiment prepares TiO 2 / C / FeS 2 The steps for composite materials are as follows:

[0043] S1. Add 0.3g of P25 TiO 2 React with 60mL of 10mol / L sodium hydroxide solution at 150°C for 24h. After the reaction, centrifuge the reaction mixture and wash the solid with deionized water to neutrality, then add the solid to 100mL of 0.1mol / L hydrochloric acid solution for Ion exchange for 24h to get H 2 Ti 3 o 7 Suspension. H 2 Ti 3 o 7 The suspension was centrifuged and the centrifuged solid was washed with deionized water until neutral.

[0044] S2, in the deionized water of 50mL, add the Tris of 5mmol tris (Tris), then add a certain amount of 0.1mol / L hydrochloric acid solution, prepare the Tris-HCl buffer solution that pH is 8.5, will obtain in the step S1 h 2 Ti 3 o 7 The solid was added to the above-mentioned Tris-HCl buffer solution, stirred evenly, and then 0.2 g of dopamine hydrochloride was added, and then magnetic stirring was continued for 48 h. ...

Embodiment 2

[0068] The difference between this embodiment and embodiment 1 is: in step S4, FeCl 2 4H 2 The consumption of O is 99.4mg, and the consumption of thioacetamide is 56.7mg (namely FeCl 2 4H 2 The mass ratio of O and thioacetamide is 1:0.57); Other contents are identical.

Embodiment 3

[0070] The difference between this embodiment and embodiment 1 is: in step S4, FeCl 2 4H 2 The consumption of O is 99.4mg, and the consumption of thioacetamide is 93.4mg (being FeCl 2 4H 2 The mass ratio of O and thioacetamide is 1:0.94); Other contents are identical.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com