Method for measuring alternating current impedance of failed battery

An AC impedance and battery technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of poor surface state of invalid battery pole pieces, cumbersome and troublesome operation steps, dangerous processes, etc., and achieve the state of appearance and internal structure Low requirements, simple and easy assembly method, accurate and fast test effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

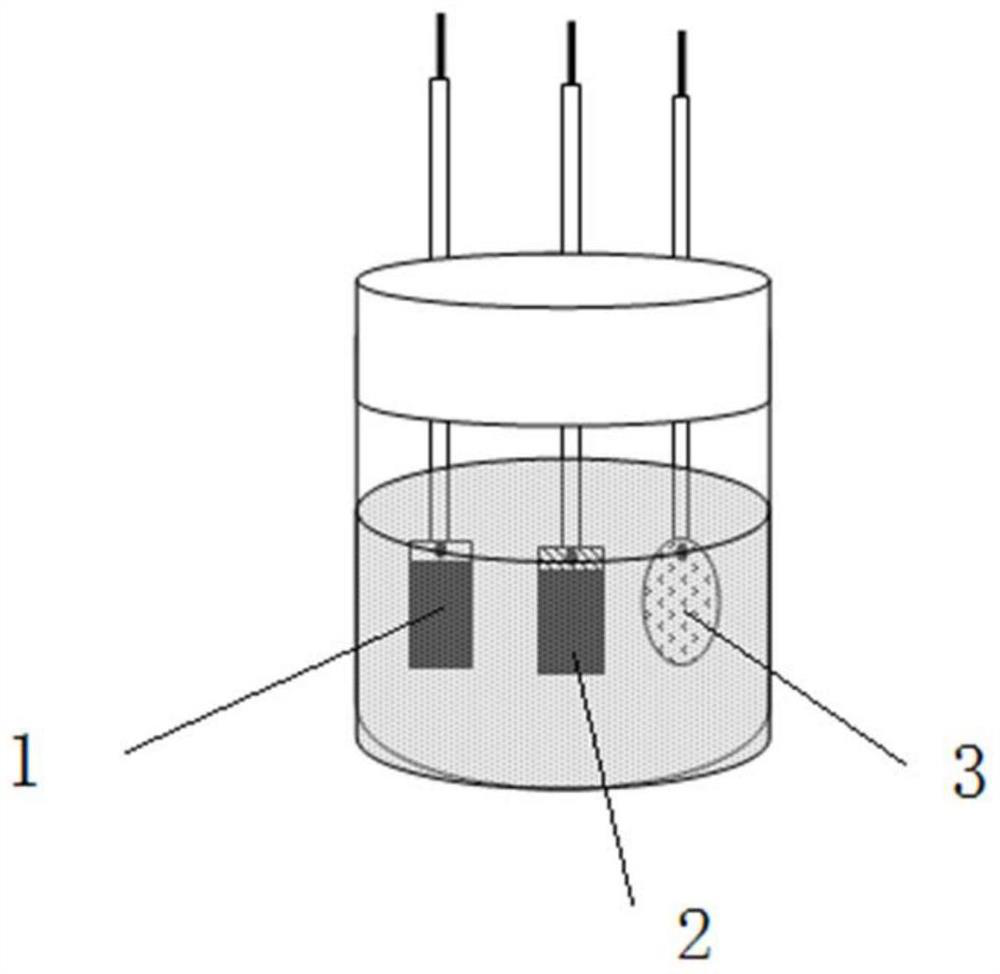

[0042] S1. Disassemble the failed battery to be analyzed, and separate the positive electrode sheet 1, the negative electrode sheet 2 and the separator. Then select the separated positive electrode piece 1 to select the area to be analyzed and cut it into a strip with a length of 1.2cm and a width of 1cm. Wipe the 0.2cm material area along the length direction until the foil material leaks out. Wipe the material area with dust-free paper dipped in NMP . Similarly, select the area to be analyzed for the separated negative electrode sheet 2 and cut it into a strip with a length of 1.2 cm and a width of 1 cm. Wipe the 0.2 cm material area along the length direction with a dust-free paper dipped in NMP, and the foil material will leak out. The positive and negative electrodes 2 avoid contact with spare, such as figure 1 shown.

[0043] S2. Clamp the positive and negative electrodes cut out in step S1 on the stainless steel electrode holder respectively, fix the position of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com