Low-reflectivity COB packaging structure

A packaging structure and low reflectivity technology, which is applied to lighting devices, air-proof/waterproof devices, lighting device components, etc., can solve problems such as low reflectivity, uneven chip power, and inconspicuous lighting effects, and achieve cost-effective Low, high luminous efficacy and high lumen density, to achieve the effect of luminous efficacy and high lumen density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

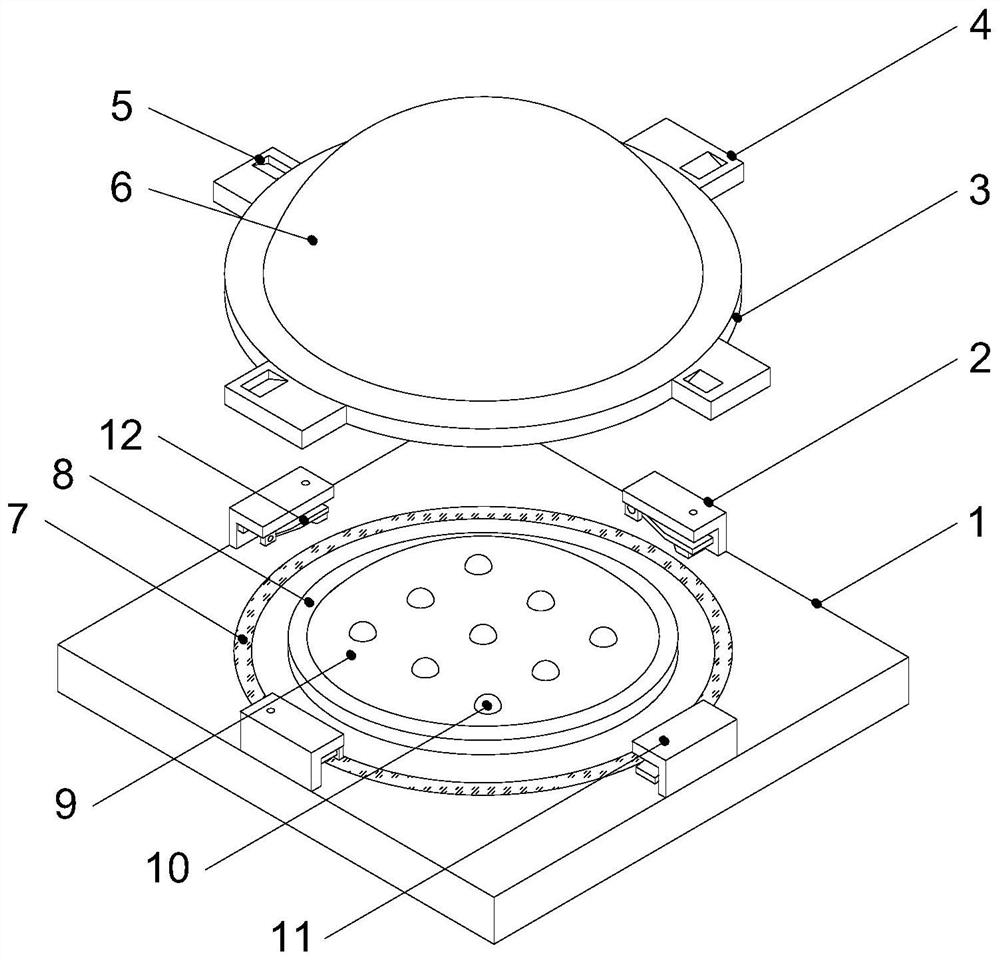

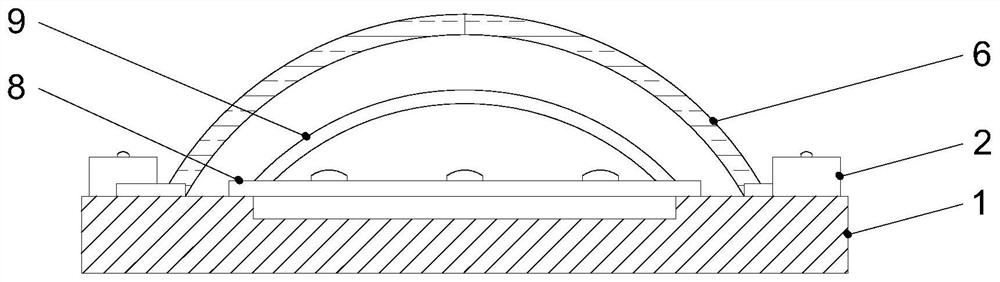

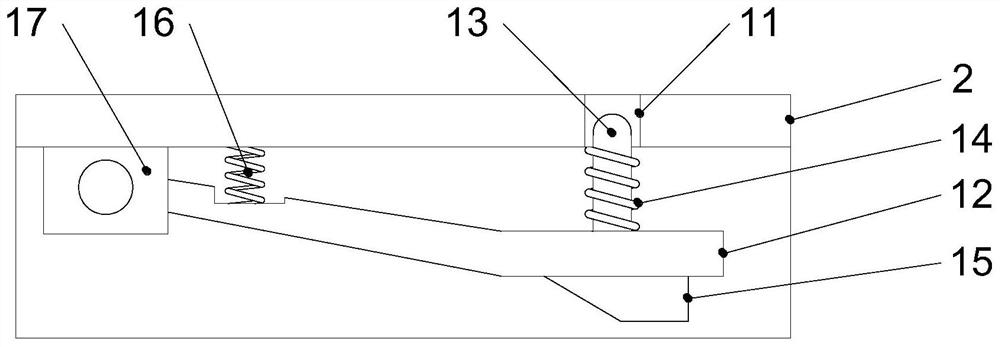

[0021] Example: such as Figure 1-3 As shown, a low-reflectivity COB packaging structure of the present invention includes a base 1, a circuit board 8 is mounted on the base 1, and an LED chip 10 is mounted on the surface of the circuit board 8, and a sealing sleeve 3 is provided directly above the base 1. And the surface of the sealing sleeve 3 is fixedly connected with a protective glass 6, and the surface of the base 1 is equipped with a plurality of clamping blocks 2, and the clamping blocks 2 are respectively fixedly connected to the middle of each side of the base 1, and the cross section of the clamping blocks 2 is " L"-shaped structure, and the limit slant plate 12 is movable in the clamping block 2, and a plurality of clamping plates 4 are fixedly installed on the surface of the sealing sleeve 3, and the clamping plates 4 and the clamping blocks 2 are set in one-to-one correspondence, and the surface of the LED chip 10 Be coated with sealant 9.

[0022] Wherein, one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com