Preparation method and application of Fe and Co bimetallic doped mesoporous carbon oxygen reduction catalyst

A bimetallic and catalyst technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problem of a large number of agglomerated single metal catalyst loading, and achieve the effects of low preparation cost, overcoming agglomeration, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

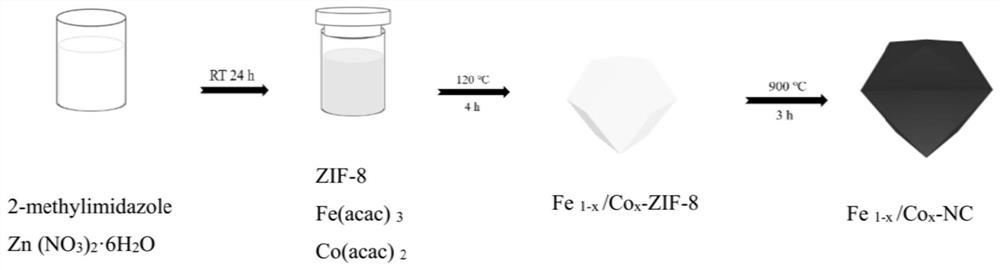

[0037] Preparation of Fe-NC catalyst:

[0038] 1.315g 2-methylimidazole was dissolved in 15.5mL methanol solution, and the obtained solution was named A solution; 1.18g hexahydrate zinc nitrate was dissolved in 30.5mL methanol solution, and the obtained solution was named B solution; Add solution B to solution A under certain conditions, and stir at room temperature for 24h to obtain a white suspension ZIF-8, then add 0.67mmol iron (III) acetylacetonate and 0mmol cobalt (II) acetylacetonate to it, and then Stir for 1 hour, then transfer to polytetrafluoroethylene for hydrothermal reaction at 120°C for 4 hours, the product obtained is centrifuged, washed with ethanol three times, and dried in vacuum at 60°C. The above product was transferred to a porcelain boat, placed in a tube furnace for heat treatment at 900 °C in a nitrogen atmosphere for 3 h, and the heating rate of the nitrogen gas was controlled to be 5 °C / min, and the obtained product was recorded as Fe-NC.

Embodiment 2

[0040] Fe 0.9 / Co 0.1 - Preparation of NC catalyst:

[0041] 1.315g 2-methylimidazole was dissolved in 14.5mL methanol solution, and the obtained solution was named A solution; 1.20g zinc nitrate hexahydrate was dissolved in 29.5mL methanol solution, and the obtained solution was named B solution; Add solution B to solution A under certain conditions, and stir at room temperature for 24h to obtain a white suspension ZIF-8, then add 0.6mmol iron (III) acetylacetonate and 0.07mmol cobalt (II) acetylacetonate to it, Stir for another 1 hour, transfer to polytetrafluoroethylene and conduct a hydrothermal reaction at 120°C for 4 hours. The obtained product is centrifuged, washed with ethanol three times, and vacuum-dried at 60°C. The above product was transferred to a porcelain boat, placed in a tube furnace and heat-treated at 900 °C for 3 h in a nitrogen atmosphere, and the heating rate of the nitrogen gas was controlled to be 5 °C / min. The obtained product was denoted as Fe 0....

Embodiment 3

[0043] Fe 0.7 / Co 0.3 - Preparation of NC catalyst:

[0044] 1.314g 2-methylimidazole was dissolved in 15.0mL methanol solution, and the obtained solution was named A solution; 1.19g zinc nitrate hexahydrate was dissolved in 30.0mL methanol solution, and the obtained solution was named B solution; Add solution B to solution A under certain conditions, and stir at room temperature for 24 hours to obtain a white suspension ZIF-8, then add 0.47 mmol iron (III) acetylacetonate and 0.2 mmol cobalt (II) acetylacetonate to it, Stir for another 1 hour, transfer to polytetrafluoroethylene and conduct a hydrothermal reaction at 120°C for 4 hours. The obtained product is centrifuged, washed with ethanol three times, and vacuum-dried at 60°C. The above product was transferred to a porcelain boat, placed in a tube furnace and heat-treated at 900 °C for 3 h in a nitrogen atmosphere, and the heating rate of the nitrogen gas was controlled to be 5 °C / min. The obtained product was denoted as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com