Multi-feed packaging antenna based on fan-out packaging

An antenna and feeder technology, applied in the field of multi-feed packaged antennas, to achieve the effect of eliminating loss, realizing beam performance and wide beam performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

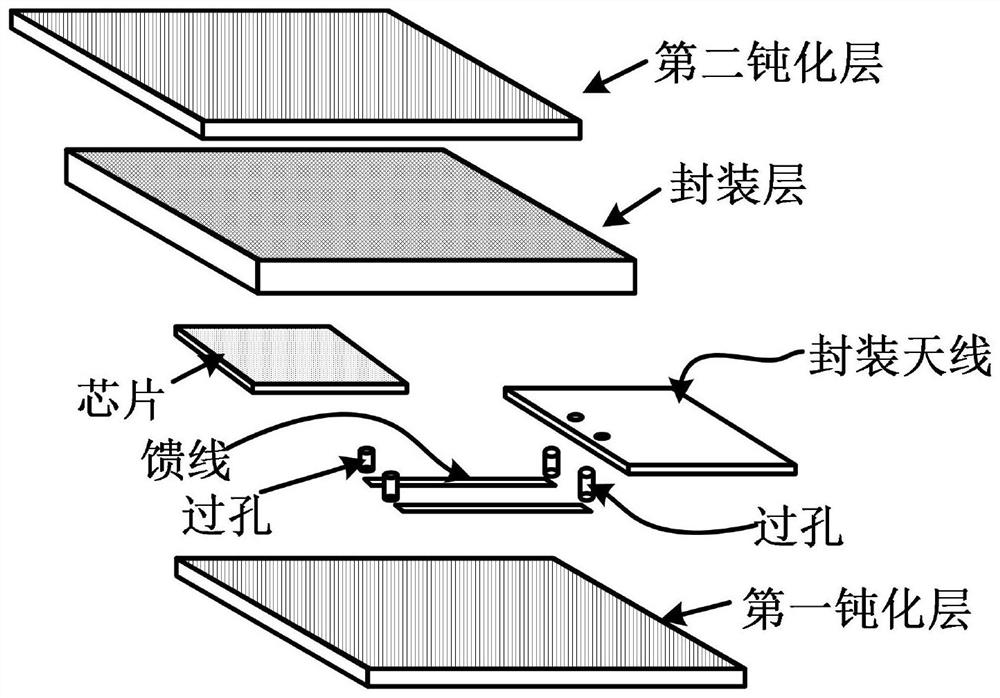

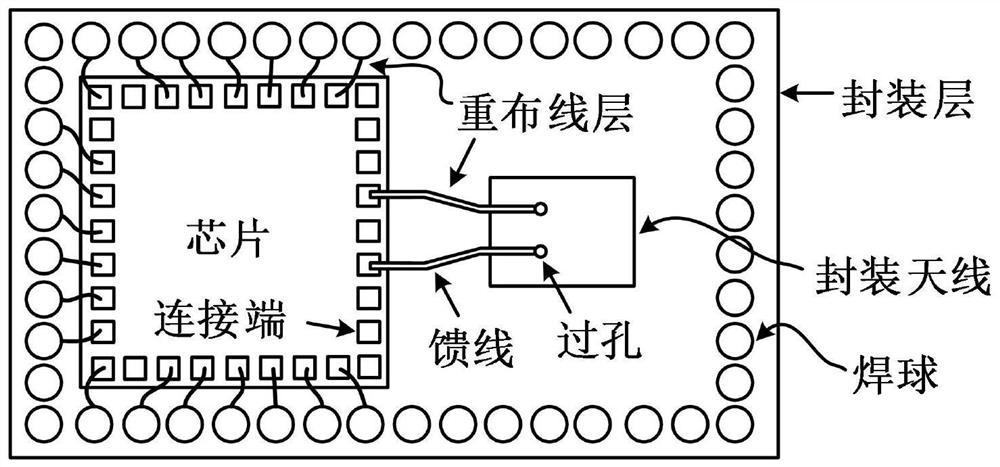

[0049] like figure 1 As shown, taking the double-fed packaged antenna as an example, the implementation process of this embodiment is described in detail:

[0050] Doubly-fed package antenna based on fan-out package, including package layer, chip and package antenna;

[0051] The chip is a millimeter wave chip, the chip is embedded in the packaging layer, the chip is embedded in the packaging layer, and the side where the chip connection terminal is located is exposed, for example, the lower end surface of the chip and the lower end surface of the packaging layer are located on the same plane.

[0052] Considering that in the traditional fan-out packaging process, the packaging layer adopts plastic packaging, and the physical performance of the chip is improved by using a thicker packaging material on top of the chip. However, the plastic packaging material used in fan-out packaging has high processing costs and high loss, and has a higher curvature than glass, and in the mill...

Embodiment 2

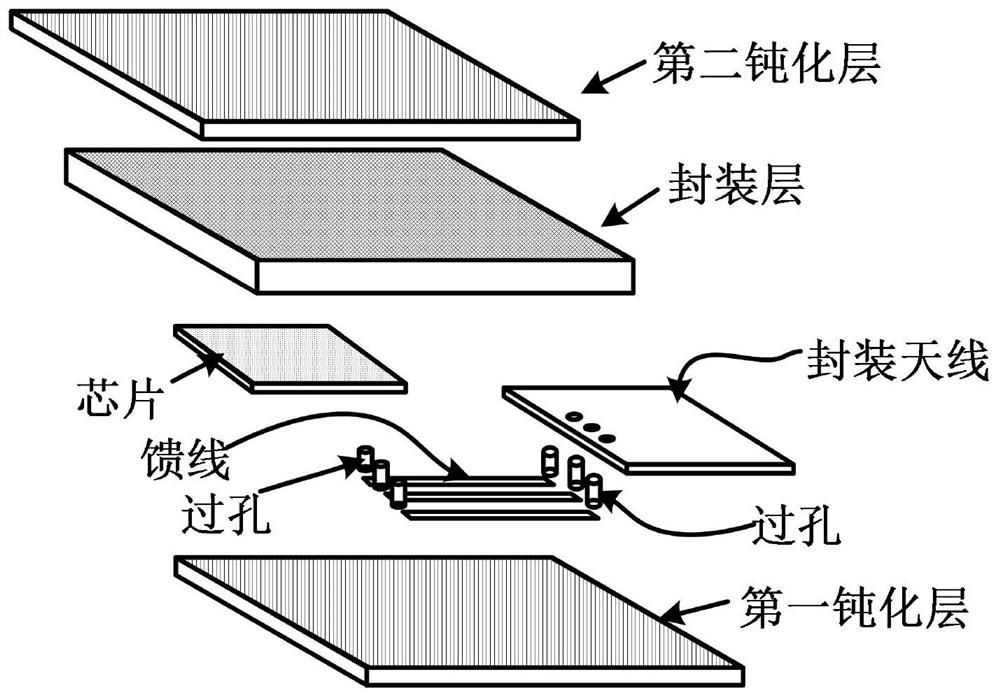

[0065] like image 3 As shown, taking the three-feed packaged antenna as an example, the implementation process of this embodiment will be described in detail:

[0066] Doubly-fed package antenna based on fan-out package, including package layer, chip and package antenna;

[0067] Doubly-fed package antenna based on fan-out package, including package layer, chip and package antenna;

[0068] The chip is a millimeter wave chip, the chip is embedded in the packaging layer, the chip is embedded in the packaging layer, and the side where the chip connection terminal is located is exposed, for example, the lower end surface of the chip and the lower end surface of the packaging layer are located on the same plane.

[0069] Considering that in the traditional fan-out packaging process, the packaging layer adopts plastic packaging, and the physical performance of the chip is improved by using a thicker packaging material on top of the chip. However, the plastic packaging material u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com