Adsorbing material as well as preparation method and application thereof

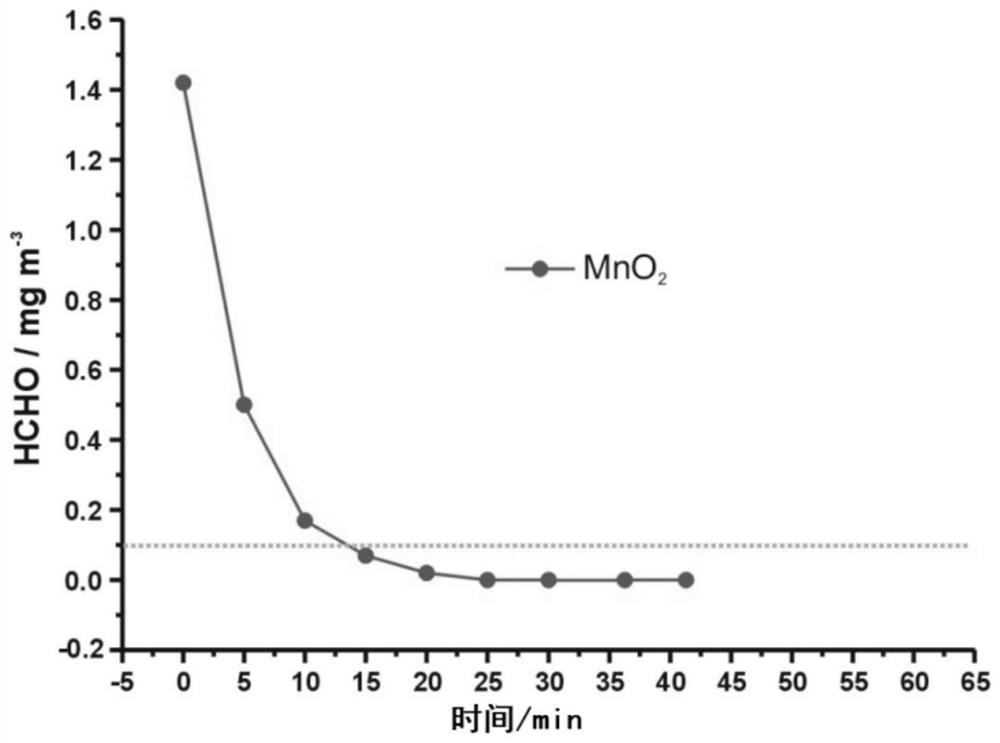

An adsorption material and reaction technology, applied in the field of adsorption material and its preparation, can solve the problems of complex preparation process, unfavorable industrial production, unsatisfactory formaldehyde removal efficiency, etc., and achieves mild peak shape, good formaldehyde removal effect, and better purification effect. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

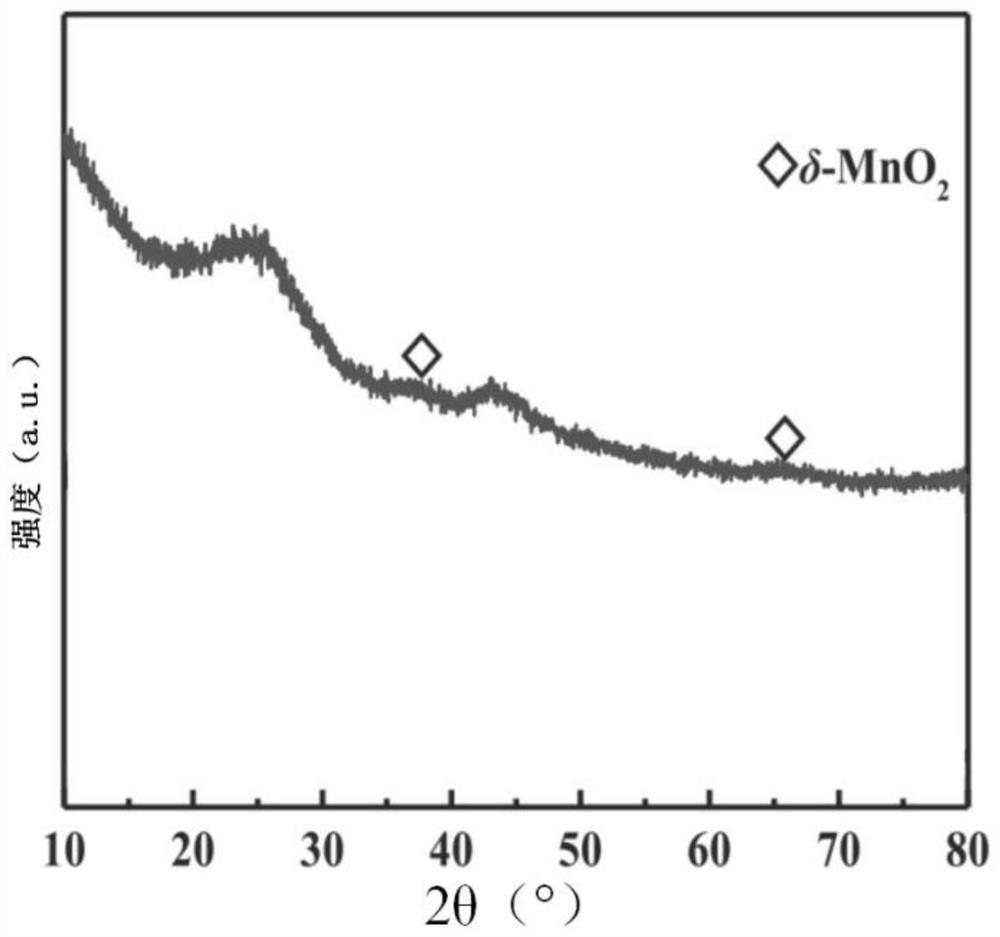

[0056] Embodiment 1 A kind of granular manganese dioxide adsorbent material

[0057] The present embodiment provides a kind of preparation method of granular manganese dioxide adsorption material, comprising:

[0058] (1) Potassium manganate is added in water, stirred to dissolve, and preparation concentration is the potassium manganate aqueous solution of 0.2g / ml;

[0059] (2) Add ethanol in described potassium manganate aqueous solution, every 1g potassium manganate adds 20ml ethanol;

[0060] (3) stirring and reacting for a certain period of time at room temperature, judging whether the reaction is complete according to the reaction temperature curve, obtaining a manganese dioxide suspension;

[0061] Wherein, the reaction temperature curve means that the reaction is complete when the temperature no longer drops; in the present embodiment, the reaction is carried out after 600min and the reaction is complete;

[0062] (4) The manganese dioxide suspension is subjected to s...

Embodiment 2

[0068] Embodiment 2 A kind of powdery manganese dioxide adsorption material

[0069] The present embodiment provides a kind of preparation method of powdery manganese dioxide adsorption material, comprising:

[0070] (1) Potassium manganate is added in water, stirred to dissolve, and preparation concentration is the potassium manganate aqueous solution of 0.2g / ml;

[0071] (2) Add ethanol in described potassium manganate aqueous solution, every 1g potassium manganate adds 20ml ethanol;

[0072] (3) stirring and reacting for a certain period of time at room temperature, judging whether the reaction is complete according to the reaction temperature curve, obtaining a manganese dioxide suspension;

[0073] Wherein, the reaction temperature curve means that the reaction is complete when the temperature no longer drops; in the present embodiment, the reaction is carried out after 600min and the reaction is complete;

[0074] (4) The manganese dioxide suspension is subjected to so...

Embodiment 3

[0076] Embodiment 3 A kind of granular manganese dioxide adsorbent material

[0077] The present embodiment provides a kind of preparation method of granular manganese dioxide adsorption material, comprising:

[0078] (1) Potassium permanganate is added in water, stirred to dissolving, preparation concentration is the potassium permanganate aqueous solution of 0.02g / ml;

[0079] (2) add methyl alcohol in described potassium permanganate aqueous solution, every 1g potassium permanganate adds 5ml methyl alcohol;

[0080] (3) stirring and reacting for a certain period of time at room temperature, judging whether the reaction is complete according to the reaction temperature curve, obtaining a manganese dioxide suspension;

[0081] Wherein, the reaction temperature curve indicates that when the temperature no longer drops, it means that the reaction is complete; in the present embodiment, the reaction is carried out after 700min and the reaction is complete;

[0082] (4) The man...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com