Polymer dispersed liquid crystal film prepared by using photomask and preparation method thereof

A technology for dispersing liquid crystals and polymers, used in chemical instruments and methods, optics, layered products, etc., can solve the problems of high driving voltage, slow response time, and poor mechanical properties of PDLC films, and achieve faster polymerization rate and response. Increased contrast and brightness, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

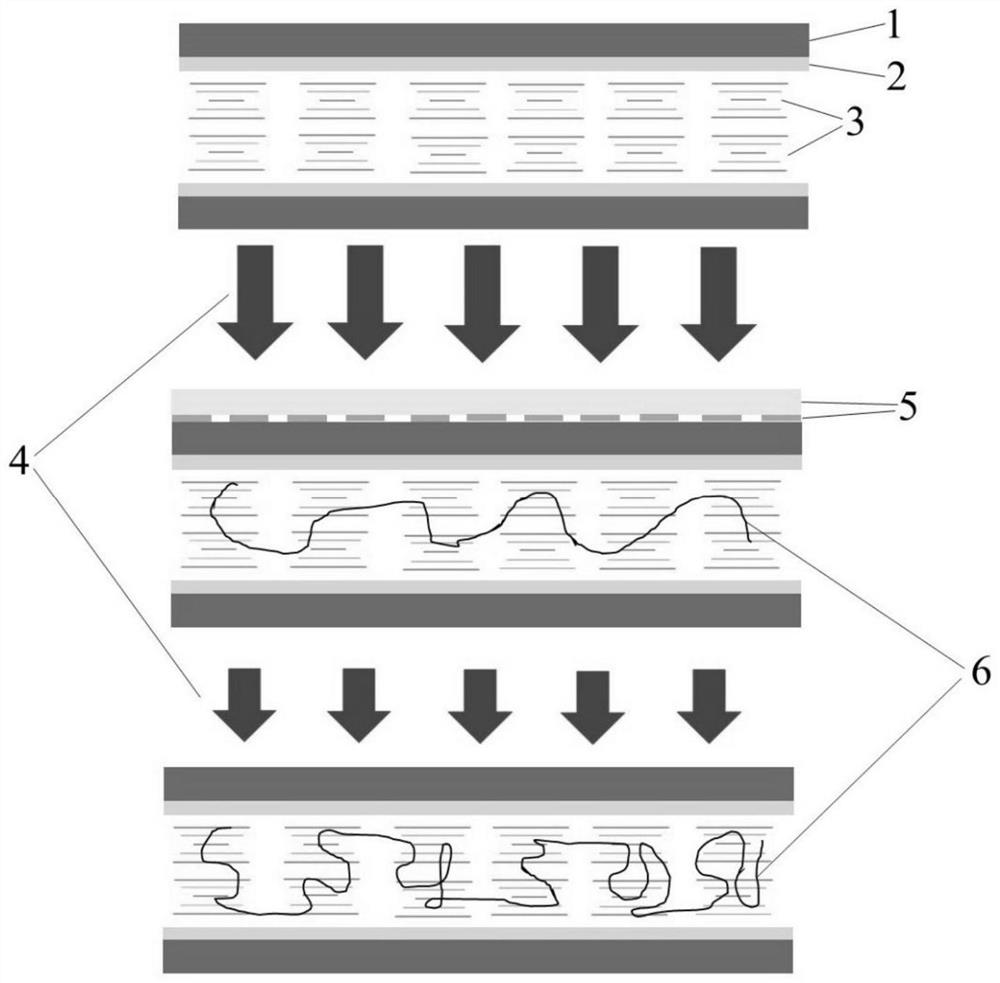

[0038]A polymer-dispersed liquid crystal film prepared by using a photomask, the first layer from top to bottom is a biaxially stretched polyester transparent conductive thin layer coated with a conductive layer on the lower side, and the second layer is a thin layer of polymer liquid crystal composite system , the third layer is a biaxially stretched polyester transparent conductive thin layer coated with a conductive layer on the upper side. The conductive layer is a silver nanowire / poly(3-hexylthiophene) composite conductive material with a resistivity of 10Ω / cm, a light transmittance of 85%, and a thickness of 10nm.

[0039] The polymer liquid crystal composite thin layer is made of the following raw materials by weight: 1 part of nematic liquid crystal, 1 part of polymerizable monomer mixture, 0.2 part of photoinitiator mixture, and 0.1 part of ultraviolet absorber mixture.

[0040] The thickness of the thin layer of the polymer liquid crystal composite system is 20 μm. ...

Embodiment 2

[0055] A polymer-dispersed liquid crystal film prepared by using a photomask, the first layer from top to bottom is a biaxially stretched polyester transparent conductive thin layer coated with a conductive layer on the lower side, and the second layer is a thin layer of polymer liquid crystal composite system , the third layer is a biaxially stretched polyester transparent conductive thin layer coated with a conductive layer on the upper side.

[0056] The conductive layer is a silver nanowire / poly(3-hexylthiophene) composite conductive material with a resistivity of 800Ω / cm, a light transmittance of 95%, and a thickness of 30nm.

[0057] The polymer liquid crystal composite thin layer is made of the following raw materials by weight: 50 parts of nematic liquid crystal, 50 parts of polymerizable monomer mixture, 5.0 parts of photoinitiator mixture, and 1.5 parts of ultraviolet absorber mixture.

[0058] The thickness of the thin layer of the polymer liquid crystal composite s...

Embodiment 3

[0073] A polymer-dispersed liquid crystal film prepared by using a photomask, the first layer from top to bottom is a biaxially stretched polyester transparent conductive thin layer coated with a conductive layer on the lower side, and the second layer is a thin layer of polymer liquid crystal composite system , the third layer is a biaxially stretched polyester transparent conductive thin layer coated with a conductive layer on the upper side. The conductive layer is a silver nanowire / poly(3-hexylthiophene) composite conductive material with a resistivity of 400Ω / cm, a light transmittance of 90%, and a thickness of 20nm.

[0074] The polymer liquid crystal composite thin layer is made of the following raw materials by weight: 25 parts of nematic liquid crystal, 25 parts of polymerizable monomer mixture, 2.50 parts of photoinitiator mixture, and 0.8 part of ultraviolet absorber mixture.

[0075] The thickness of the thin layer of the polymer liquid crystal composite system is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com