Stable isotope <13>C skeleton labeled graphite and graphene oxide, preparation method, and application of graphene oxide

A stable isotope, graphene technology, applied in the field of graphene, can solve problems such as impurities, and achieve the effect of simple and feasible synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] According to the present invention 13 The preparation method of the graphite oxide marked by C skeleton, the method comprises the steps:

[0027] (i) Drill the graphite electrode along the axis of the electrode and fill the hole 13 C amorphous carbon powder;

[0028] (ii) Fill step (i) with 13 C. The graphite electrode of amorphous carbon powder is packed in a DC arc discharge reaction furnace as a discharge anode; (iii) under vacuum conditions, in the presence of hydrogen and helium, the discharge cathode is contacted with the discharge anode, and the arc is ablated The discharge anode described in step (ii);

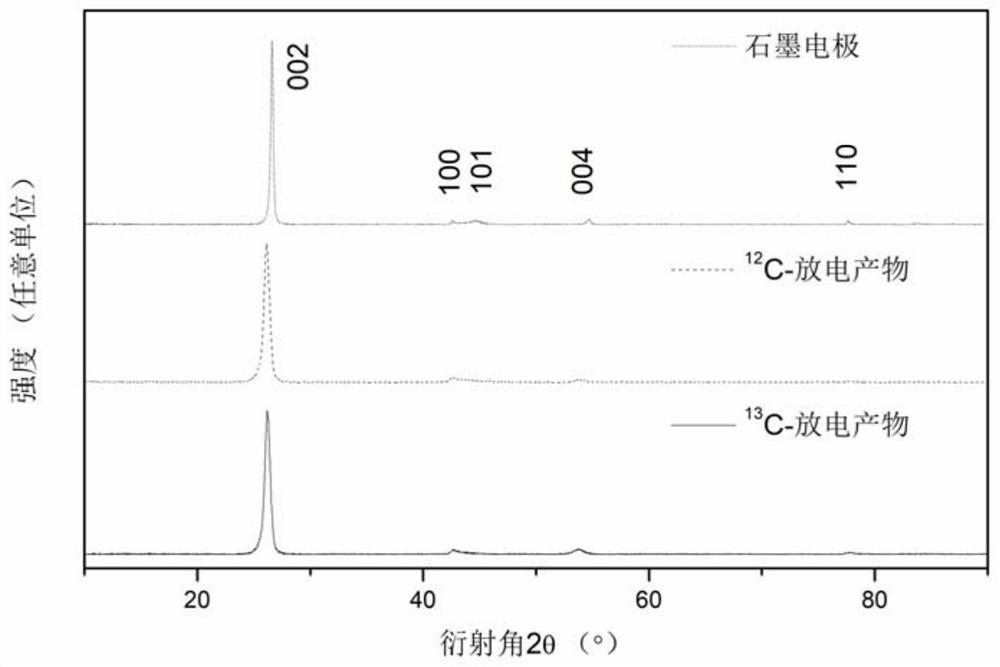

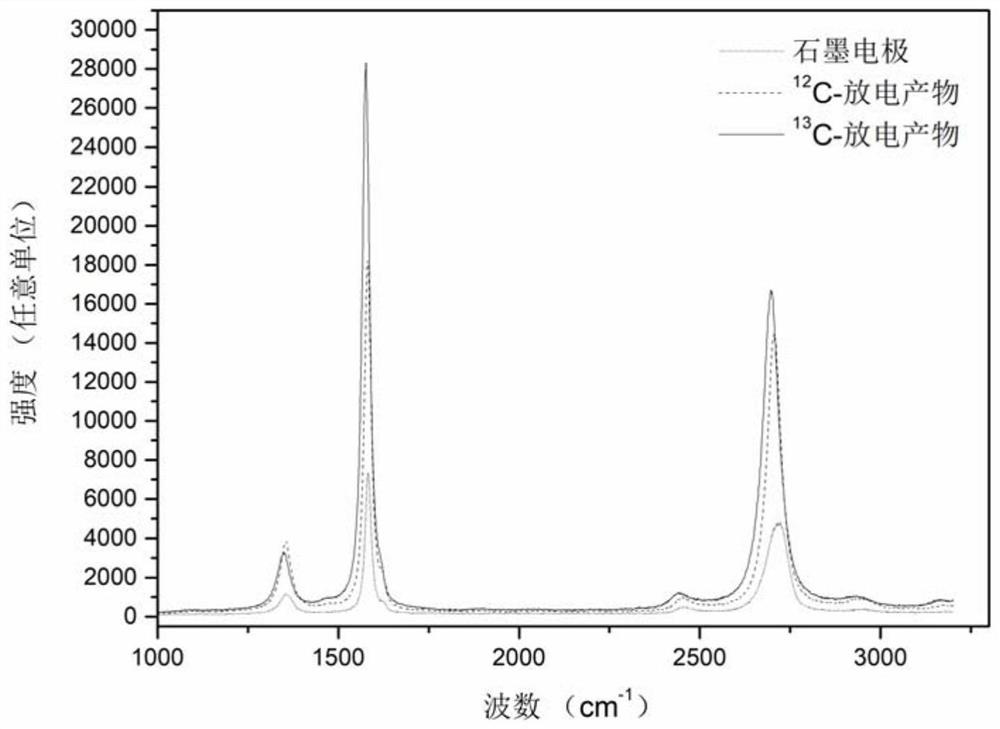

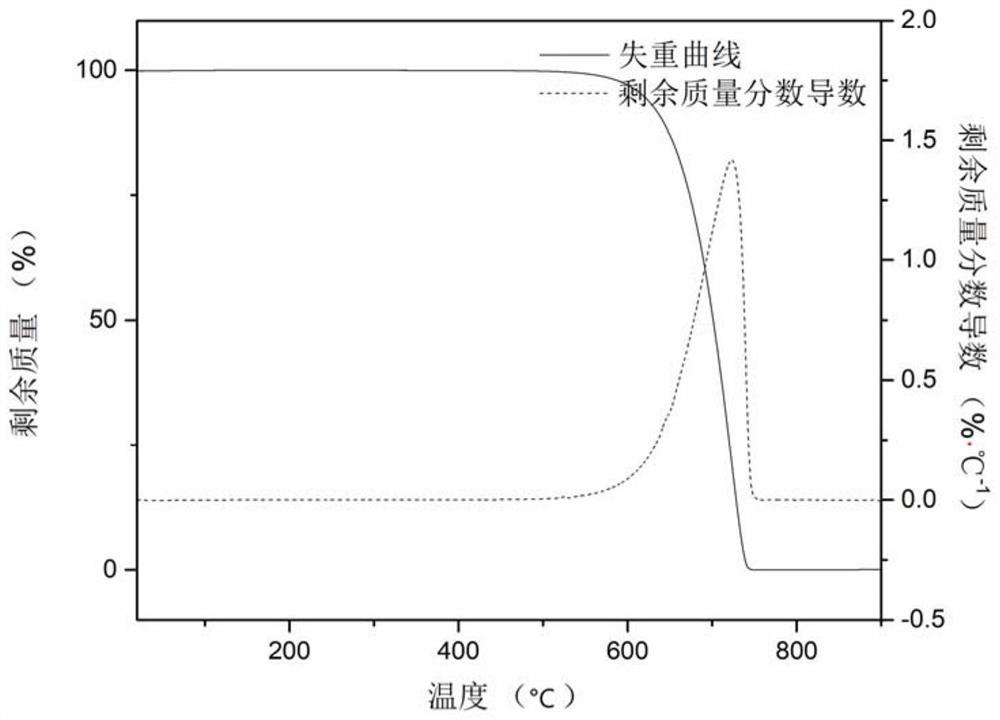

[0029] (vi) Collect the deposits on the discharge cathode, pulverize the collected deposits to obtain stable isotopes 13 C skeleton labeled graphite.

[0030] According to the method of the present invention, the present invention for graphite electrode in step (i): 13 The mass ratio of the C amorphous carbon powder is not particularly limited, and can var...

Embodiment 1

[0046] (i) A graphite electrode with a diameter of 1 cm and a length of 12 cm is drilled along the electrode axis. The diameter of the hole obtained is 6 mm and the depth is 11.8 cm. The mass of the graphite electrode after drilling is 10.30 g. Fill the hole with 1.74g of 13 C amorphous carbon powder;

[0047] (ii) Fill step (i) with 13 The graphite electrode of C amorphous carbon powder is put into a DC arc discharge reaction furnace as a discharge anode, and vacuumized, and then vacuumized again after introducing 600 Torr argon gas to replace the residual air;

[0048] (iii) Refill 100Torr argon as a protective gas, contact the discharge cathode with the discharge anode, adjust the current to 135A, and the power-on time is 2 minutes;

[0049] (iv) After the heating is completed, vacuumize, feed 600Torr helium, and then vacuumize again to replace the residual argon;

[0050] (v) Charge 200Torr hydrogen and 200Torr helium as the reaction atmosphere, adjust the discharge cur...

Embodiment 2

[0059] (i) A graphite electrode with a diameter of 1 cm and a length of 12 cm was drilled along the electrode axis. The diameter of the obtained hole was 6 mm and the depth was 11.8 cm. The mass of the graphite electrode after drilling was 6.86 g. Fill in the hole according to the mass ratio of 1:1 13 C and 12 C Amorphous carbon powder, charged 13 The mass of C amorphous carbon powder is 0.84g.

[0060] (ii) Fill step (i) with 13 C The graphite electrode of amorphous carbon powder is put into a DC arc discharge reaction furnace as a discharge anode, and vacuumized, and then 600 Torr of argon gas is introduced and then vacuumed again to replace the residual air.

[0061] (iii) Fill again with 100 Torr argon as a protective gas, connect the discharge cathode to the discharge anode, adjust the current to 135A, and the power-on time to 2 minutes.

[0062] (iv) After the heating is completed, vacuumize, feed 600Torr helium gas, and then vacuumize again to replace the residual a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com