Microbial capsule for tailing remediation and three-in-one tailing in-situ remediation method

An in-situ repair, three-in-one technology, applied in the direction of solid waste removal, fixation on or in inorganic carriers, etc., to achieve the effects of strong stability, strong isolation performance, and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

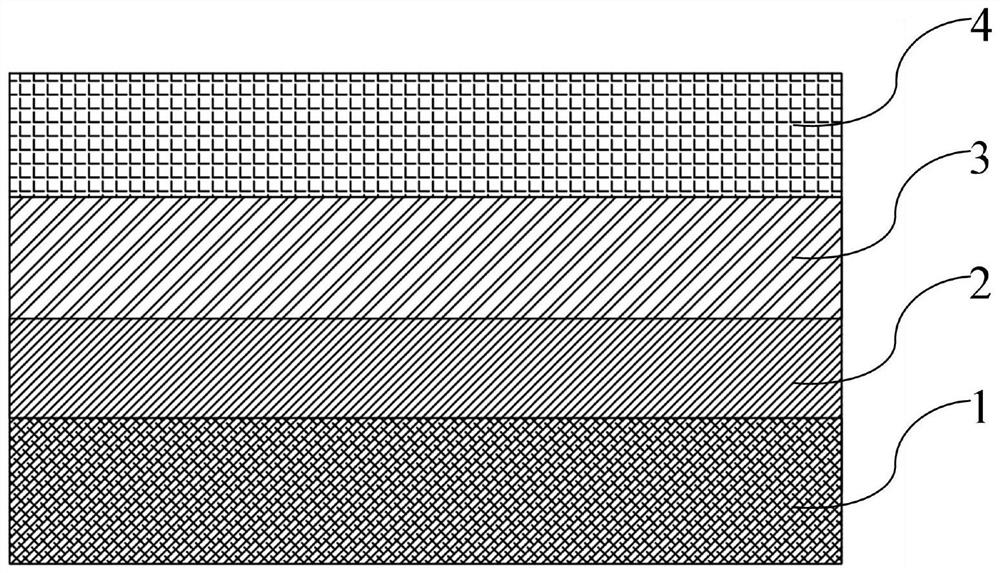

[0038] According to the aforementioned method, the contaminated tailings of a pyrite mine in Zhejiang were treated. The present embodiment selects pyrite heavy metal contaminated tailings to carry out the restoration experiment, which specifically includes the following steps: (1) raw material preparation: carry out bagging and washing with acid tailings soil, then add oxidant and fully stir to make it react, and then carry out Press filter, spare. (2) First, ore sand and microbial capsules are mixed and filled into the bottom layer of the tailings pond; then, the above-mentioned modified environmental minerals are evenly spread on the bottom layer of the acid tailings waste land, and the spreading thickness is 40cm. (3) Use microorganisms to pre-oxidize the tailings, and then mix catalysts and oxidants in the tailings to rapidly oxidize the tailings, and collect and treat the formed acidic wastewater in time. Add the pre-oxidized tailings sand and mix it evenly with the cata...

Embodiment 2

[0041] According to the aforementioned method, an acid tailings contaminated site in Gansu was treated. Add a mass fraction (relative) of 8.5% of the mixed agent to the acid tailings polluted site. After the contaminated soil is fully mixed with the agent, after natural aging, in the restored site, the organic matter content of the restored polluted soil increases by 35% %, the soil pH is significantly reduced, and the site can be used as planting soil. Concretely include the following steps: (1) Raw material preparation: bag the acid tailings sand, wash it with water, add an oxidizing agent and stir it sufficiently to make it react, and then carry out pressure filtration for standby. (2) First, ore sand and microbial capsules are mixed and filled into the bottom layer of the tailings pond; then, the above-mentioned modified environmental minerals are evenly spread on the bottom layer of the acid tailings waste land, and the spreading thickness is 40cm. (3) Use microorganisms...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com