Split stamping and splicing type weaving shuttle of fishing net weaving machine and assembling method of split stamping and splicing type weaving shuttle

A splicing and loom technology, applied in the direction of weaving auxiliary equipment, textiles, shuttles, etc., can solve the problems of high assembly workload and assembly precision, unreasonable design of weaving shuttle structure, and consumption of precious metal brass, etc., to achieve production High efficiency, improved scope of application, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

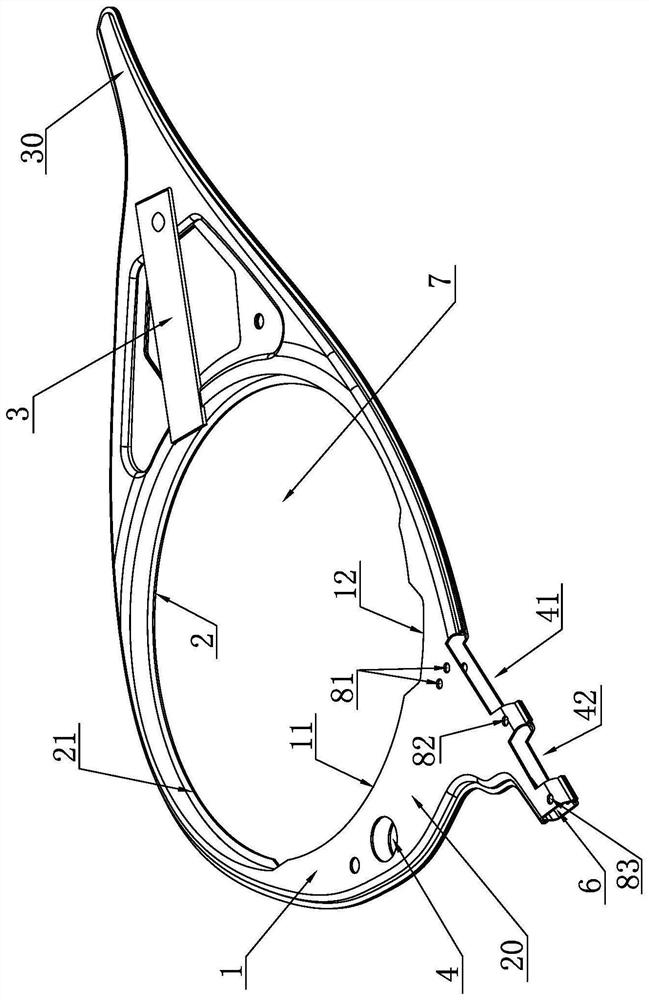

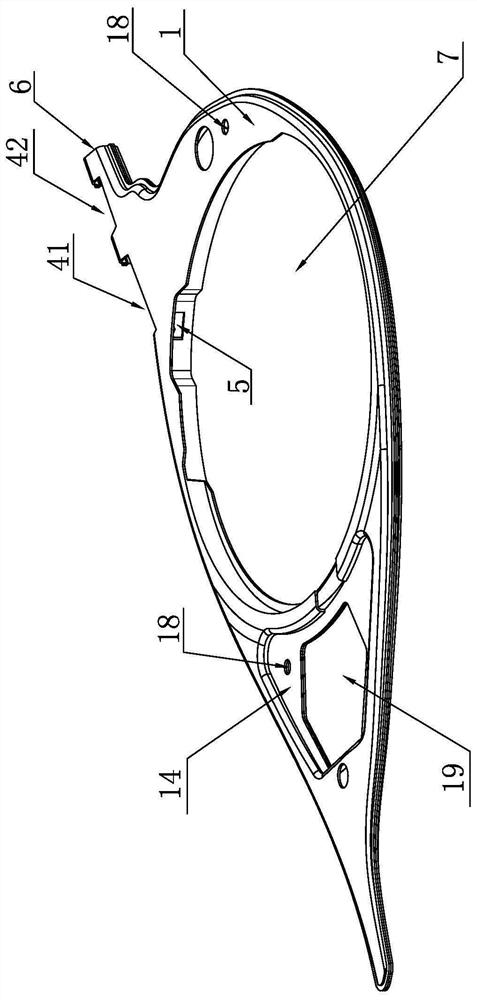

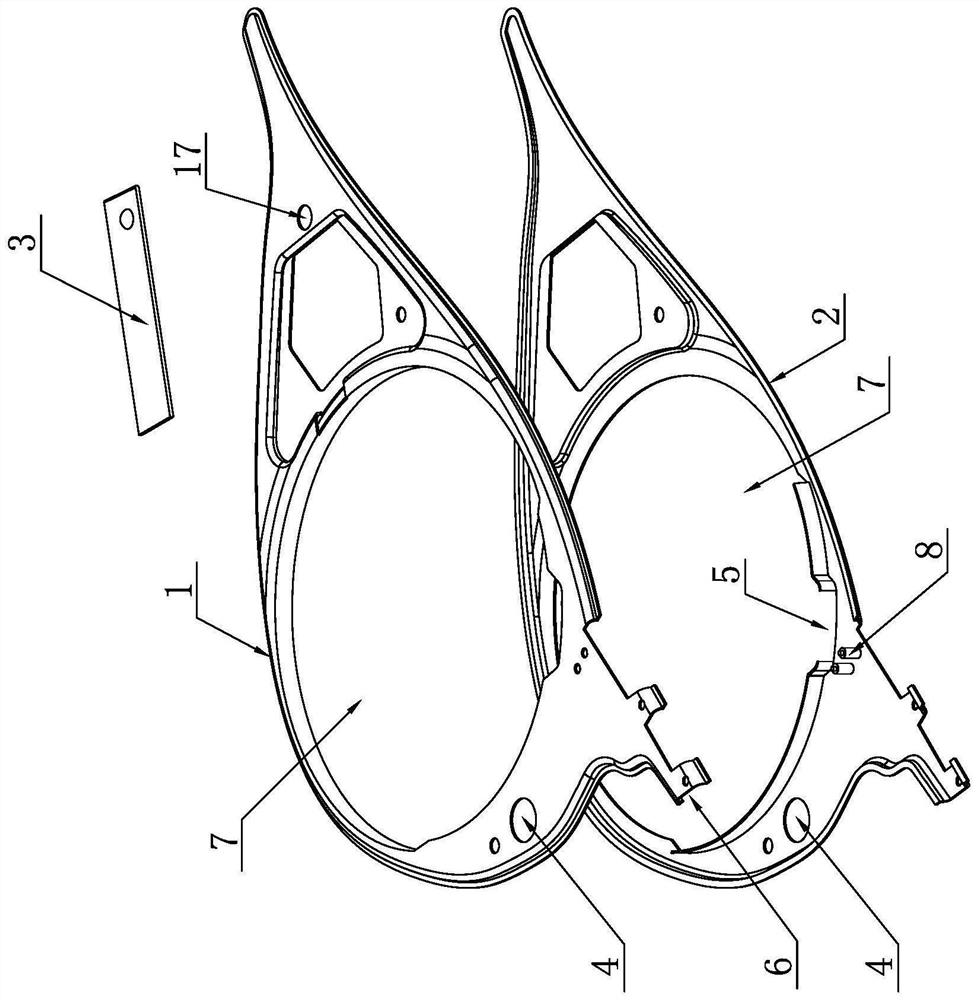

[0033] A split stamping splicing weaving shuttle of a fishing net loom, such as Figure 1-6 As shown, it includes a shuttle case 1, a bobbin case seat 2, a pressing piece 3, a photoelectric switch installation hole 4, an inlet hole 5, and an outlet hole 6. The shuttle case 1 and the bobbin case seat 2 are all stainless steel stamping parts, The periphery of the bobbin case seat 2 is provided with an upward connection flange, the bottom plate of the bobbin case seat 2 is provided with a photoelectric switch mounting hole 4 and a wire reel hole 7, and the bottom of the wire reel hole 7 is provided with a horizontally arranged seating edge 21 and The vertically upward inner side 22 is provided with a wire inlet 23 on the inner side 22, and the sector angle of the seating side 21 is 240 to 300 degrees; The connecting boss 25, the lower guide post hole 24 is arranged on the shuttle head 20, and the connecting boss 25 is arranged on the shuttle tail 30;

[0034]A downward connectin...

Embodiment 2

[0037] Embodiment 2: On the basis of Embodiment 1, conduits are provided in the wire inlet hole 5 and the wire outlet hole 6 respectively, and the axes of the wire conduits are arranged horizontally and perpendicular to the axis of the coil hole 7 .

Embodiment 3

[0038] Embodiment 3: In the inner side of the wire inlet 5, two wire posts 8 are arranged at intervals, and in the inner side of the outlet hole 6, two wire posts 8 are arranged at intervals along the line. Pass between the root incoming wire guide posts 81, and draw out from the outlet hole 6 through the transition line post 82 and the outgoing line post 83.

[0039] In this example, the number of wire posts 8 is related to the applicable specification range of the network cable, the more the number of wire posts 8 is set, the larger the applicable diameter range of the network cable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com