Sealing plate for low-temperature dry space and mounting method thereof

A technology of drying space and installation method, applied in the direction of building insulation materials, floors, building components, etc., can solve the gap sealing and low-temperature expansion reserved margin design method, there is no clear technical solution, cracking, cold shrinkage deformation It is easy to leak and other problems, so as to improve the reliability and effectiveness of sealing, simplify the positioning structure, and improve the sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

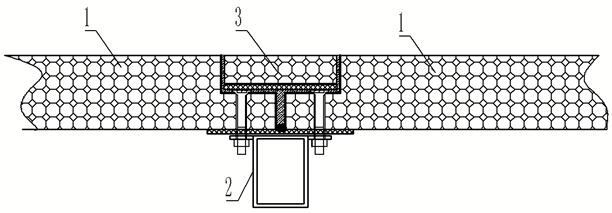

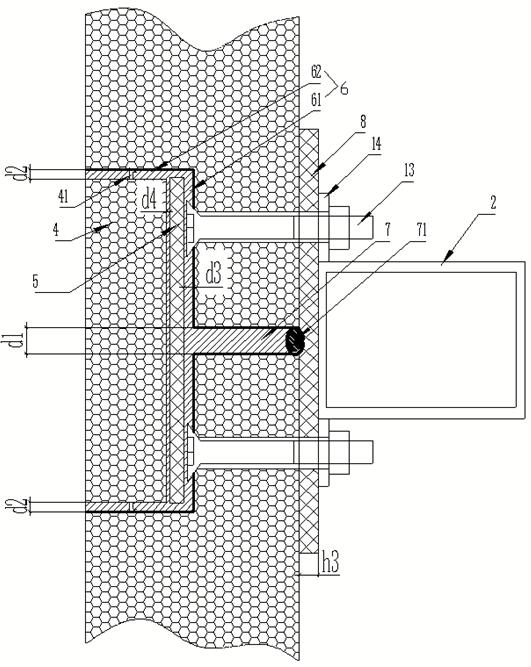

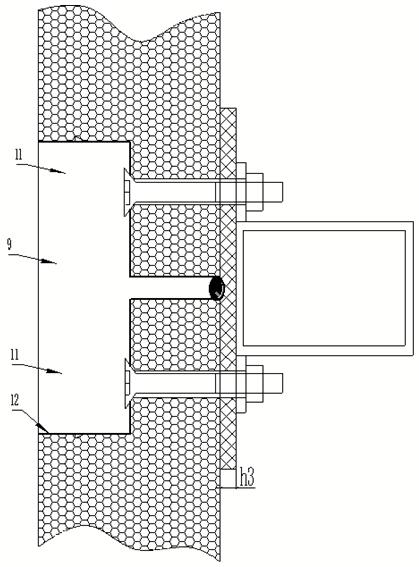

[0034] Combine below Figure 1~4 Embodiments of the present invention are described in detail.

[0035] The sealing board for low-temperature dry space, including main wall panel 1, is characterized in that: said main wall panel 1 is detachably installed on the wall keel 2 of the wall frame, and multiple adjacent main wall panels 1 are used. The turning sealing structure 3 is sealed and connected, and the multi-turning sealing structure 3 is filled with wall panels 4 and rubber pads 5 to perform secondary sealing on the seams between adjacent main wall panels 1, and make the joints in the multi-turning sealing structure 3 The sealant channel extends from the inner surface of the main wall panel 1 to the outer surface through multiple turns.

[0036] The above-mentioned sealing plate for low-temperature drying space, the adjacent main wall panels 1 are sealed and connected by a multi-turn sealing structure 3, and the sealant channel in the multi-turn sealing structure 3 is tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com