Hydraulic loosening machine and intelligent detection method thereof

A loosening machine and loosening technology, applied in the testing of machines/structural components, fluid pressure actuation system testing, mechanical equipment, etc., can solve the problems of loosening equipment and energy loss, running speed adjustment of the loosening machine, affecting normal production, etc. , to achieve high economic benefits, reduce loose resistance, and reduce a lot of time and electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Join Figure 4 , figure 2 , image 3

[0043] Set the lower limit speed: The motor speed calculated according to the propulsion speed of the loose cylinder is equal to the design of the material.

[0044] Set the upper limit speed: According to the design requirements, when the maximum material load is operated by the design of the material, the motor current is equal to the rated current, the loose cylinder can push the speed upper limit of the speed of the material to calculate the motor speed.

[0045] The motor speed can be controlled, such as frequency or voltage in the specific implementation of other parameters.

[0046] When the motor is speed up by the inverter.

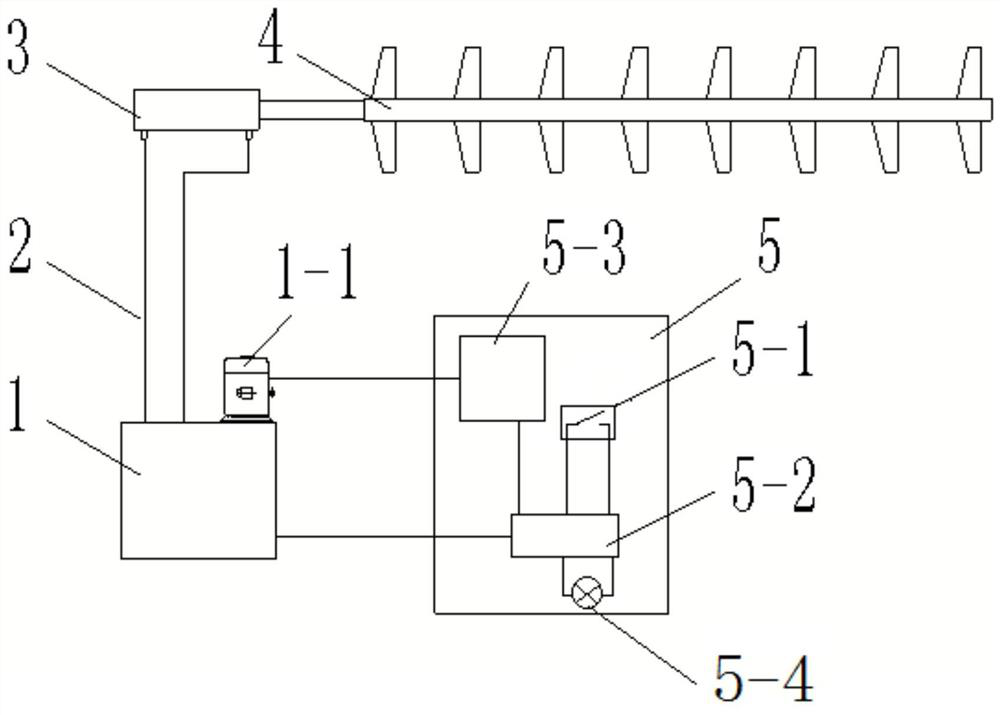

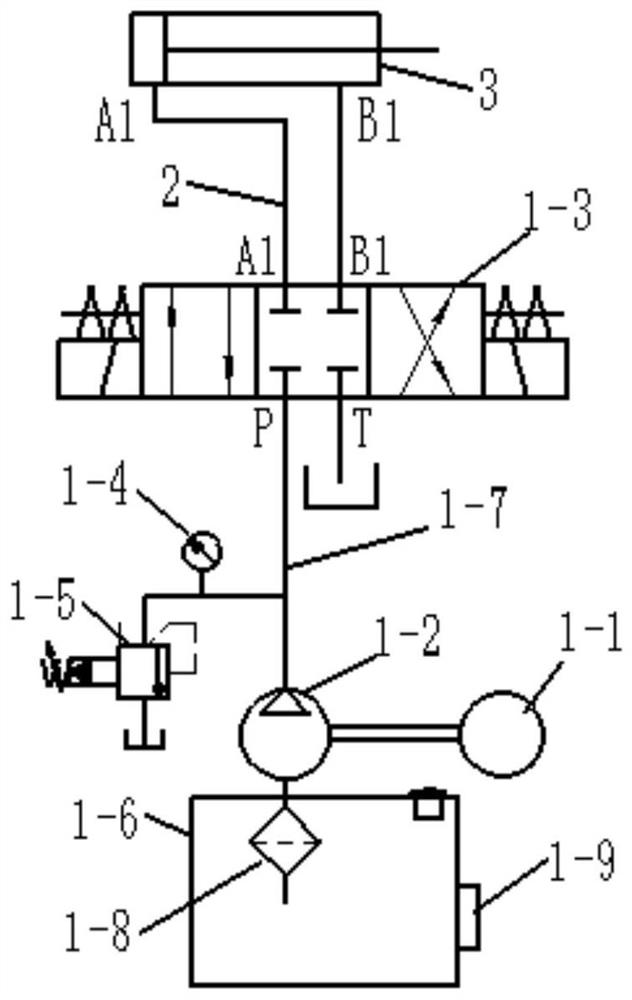

[0047] A hydraulic loose machine, including hydraulic stations 1, tubing 2, loose cylinders 3, dredger 4, and electronically controlled system 5, including motor 1-1, oil pump 1-2, electromagnetic replacement valve 1-3 , Pressure table 1-4, overflow valve 1-5, tank 1-6, tubing 1-7, oil filter 1-8 and level ...

Embodiment 2

[0062] Join Figure 5 , figure 2 , image 3

[0063] When the motor is a DC brush motor by a DC motor governor speeds up.

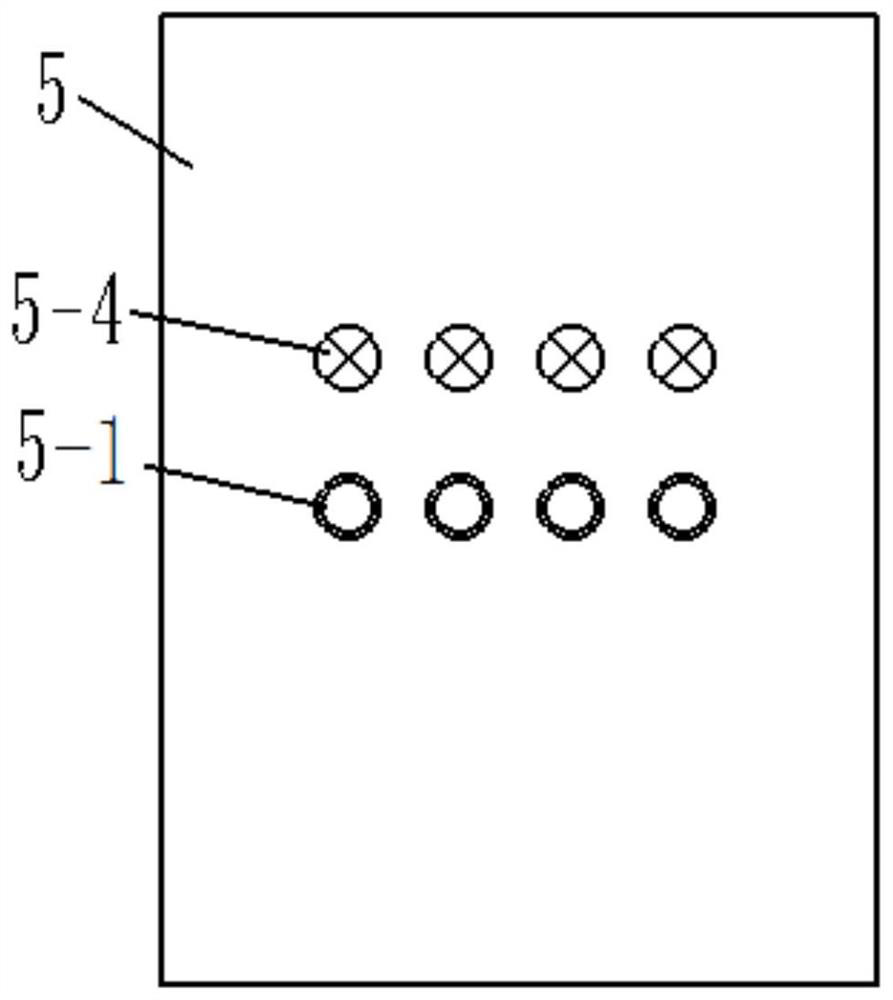

[0064] A hydraulic loose machine, including hydraulic stations 1, tubing 2, loose cylinders 3, dredger 4, and electronically controlled system 5, including motor 1-1, oil pump 1-2, electromagnetic replacement valve 1-3 , Pressure table 1-4, overflow valve 1-5, tank 1-6, tubing 1-7, oil filter 1-8 and level 1-9, the electron control system 5 includes a control switch 5-1 And indicators 5-4, the electron control system 5 also includes a industrial computer 5-2b and a DC motor governor 5-3b, and the DC motor governor 5-3b is connected to the motor 1-1, and the other end Connect to the industrial computer 5-2b, the controllers 5-2b also connect to the electromagnetic commutation valve 1-3, the control switch 5-1, and the indicator light 5-4, respectively.

[0065] The controller 5-2b can be replaced by the PLC programmable controller 5-2a.

[0066] The electron con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com