Intelligent test system for testing impact type mechanical products

A technology of mechanical products and testing systems, applied in impact testing, testing of machine/structural components, measuring devices, etc., can solve problems such as poor data accuracy, low efficiency, and poor real-time performance, and achieve the elimination of airflow pulses and fluctuations, The effect of reducing airflow pulses and fluctuations and improving the degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

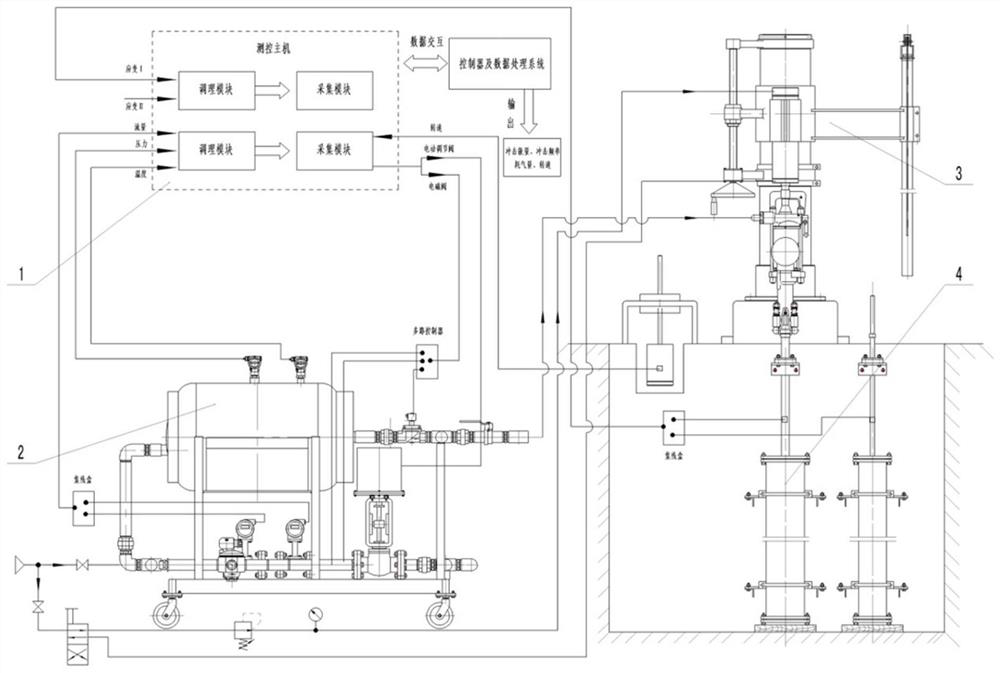

[0085] An intelligent test system for testing impact mechanical products includes a measurement and control host control system 1, a pressure flow control device 2, a vertical test bench 3 and an energy absorber group 4.

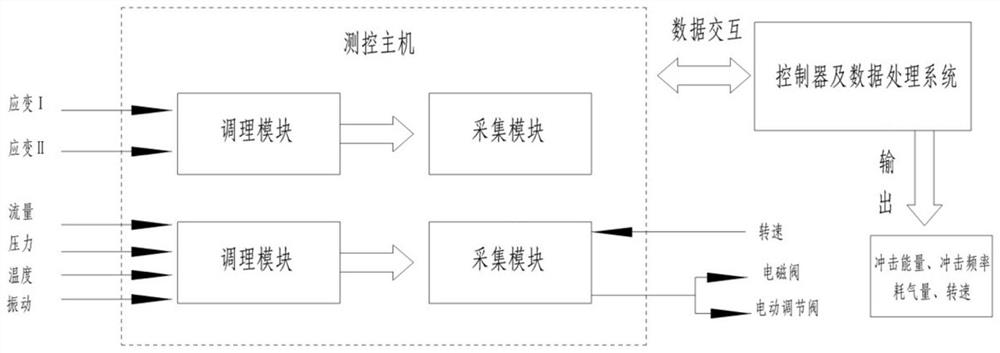

[0086] The measurement and control host control system 1 includes a signal acquisition input terminal, a measurement and control host, a controller and a data processing system. The information collected by the signal acquisition input terminal includes strain information, flow information, pressure information, temperature information, vibration information and rotational speed information.

[0087] The information signals received by the test host include strain signals, flow signals, pressure signals, temperature signals, vibration signals and rotational speed signals. The test host includes a conditioning module and an acquisition module. The conditioning module of the test host converts the collected analog signal into a digital signal and stores it in ...

Embodiment 2

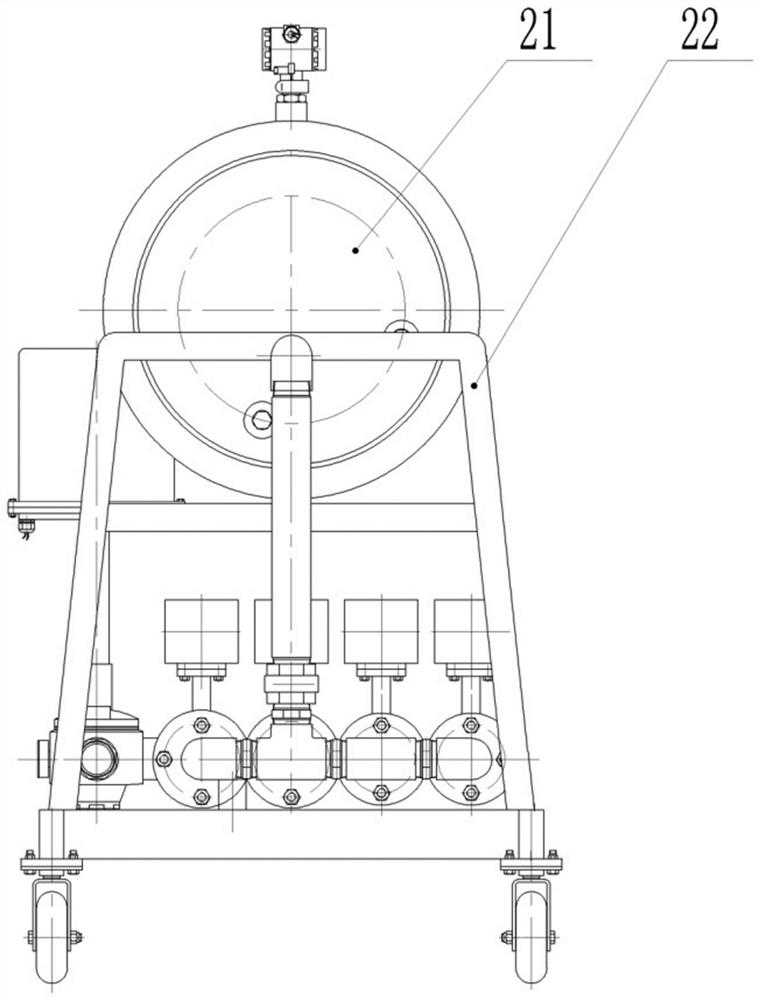

[0091] The difference between this embodiment and Embodiment 1 is that the pressure flow control device 2 includes an air storage tank 21, a vehicle frame 22, a first stop valve 23, a temperature transmitter 24, a pressure transmitter 25, and a compressed air pipeline 26 , the fourth pilot solenoid valve 27, the fourth stop valve 28, the fourth vortex flowmeter 29, the pilot pressure regulating valve 210, the second stop valve 211, the third vortex flowmeter 212, the first vortex flowmeter 213 , the second vortex flowmeter 214 , the electric control valve 215 , the third pilot solenoid valve 216 , the second pilot solenoid valve 217 , the first pilot solenoid valve 218 and the third stop valve 219 .

[0092] The compressed air pipeline 26 and the air storage tank 21 are arranged on the vehicle frame 22 . The compressed air pipeline 26 sequentially includes a first air intake main road, a parallel flow monitoring branch, a second air intake main road, a first air outlet main ro...

Embodiment 3

[0097] The difference between this embodiment and Embodiment 2 is that: the compressed air pipeline 26 also includes a cut-off branch arranged in parallel with the parallel flow monitoring branch, and the cut-off branch is provided with a third cut-off valve 219 and a second cut-off valve in sequence along the air flow direction. 211 and the fourth vortex flowmeter 29 , the outlet end of the pilot pressure regulating valve 210 communicates with the inlet end of the second cut-off valve 211 .

[0098] Working process under normal conditions: the first vortex flowmeter 213, the second vortex flowmeter 214 and the third vortex flowmeter 212 are normally open, the first stop valve 23 is opened, the second stop valve 211 and the third stop valve are closed. The stop valve 219 and the fourth stop valve 28 set the pressure value and gas consumption flow value of the test system according to the test pressure and gas consumption reference value of the tested equipment, and match the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com