Flotation pretreatment method for pyrite in cyanogen-containing and sulfur-containing tailings

A pyrite and pretreatment technology, applied in the direction of solid separation, etc., can solve the problems of reducing the decyanation flotation effect of cyanidation tailings, increasing the oxidant, and the large amount of chemicals, so as to avoid large consumption, corrosion, and treatment low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

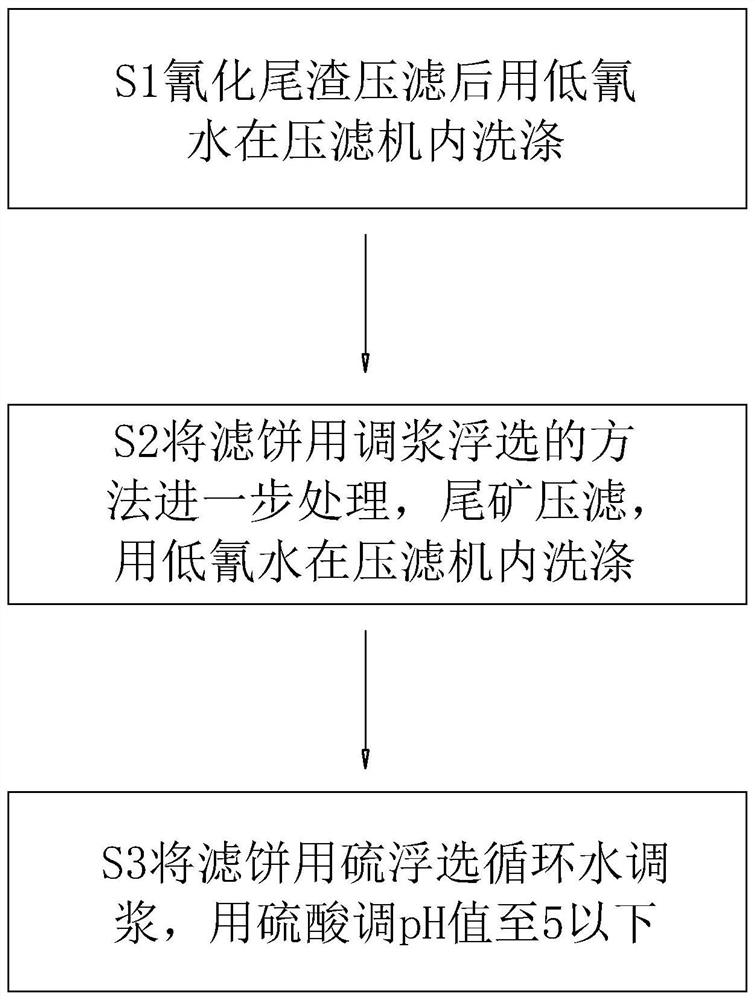

[0041] refer to figure 1 A method for flotation pretreatment of pyrite in cyanide-containing and sulfur-containing tailings, comprising the following steps:

[0042] After S1 cyanide tailings are press-filtered, they are washed in the filter press with low-cyanide water to reduce the cyanide content of the tailings;

[0043] S2 further reduces the cyanide content of the filter cake in step S1 by slurry flotation, reduces the lead and zinc content in the tailings, press-filters the tailings, and washes them in the filter press with low-cyanide water; the solids after washing The total cyanide content is less than 1g / kg, and the easy-release cyanide content is less than 0.5g / kg; the pH of slurry washing and filter washing are both greater than 9.5; the water used for flotation and washing water needs to be replaced and regenerated regularly;

[0044] S3 Slurry the filter cake in step S2 with sulfur flotation circulating water, adjust the pH value to below 5 with sulfuric acid, ...

Embodiment 2

[0048] The cyanide-containing tailings are adjusted to a concentration of about 40%, the pH is adjusted to 9-11, and the flotation lead-zinc and concentrate tailings are filtered separately to reduce the lead-zinc content of the sulfur flotation concentrate and initially reduce harmful impurities in the tailings content.

[0049] Then the tailings filter cake is washed with water with low total cyanide content, the pH of the washing water is greater than 9, and the pH is further reduced by washing. When the pH is above 9 during washing, the effect of dissolving impurities is better.

[0050] Finally, the filter cake is adjusted to a slurry, so that the stirring is even and does not sit on the bottom. Add sulfuric acid to adjust the pH to about 3, and stir for 0.5 hours to stabilize the pH at about 3. Then add alkali to adjust the pH to 5-8, and add water to a concentration of 40%. ~50%, the obtained pulp is the treated pulp, which is flotation with butyl xanthate. According t...

Embodiment 3

[0052] The total cyanide content of cyanidation tailings is 1.7g / Kg to 2.0g / Kg, and the sulfur content is about 28%. After slurry adjustment, it enters the lead-zinc flotation process. After production, the total cyanide content of the flotation circulating water increases, and the total cyanide is controlled below 3000 mg / L by decyanation treatment of part of the circulating water.

[0053] The lead-zinc flotation tailings are dehydrated with a filter press, and the filter cake is backwashed with treated low-cyanide washing water. The pH of the washing is above 10, and the weight ratio of the washing water to the filter cake is about 1. At this time, the water content of the filter cake is about 15%. The cyanide content is about 0.6g / Kg.

[0054] The lead-zinc flotation tailings filter cake is slurried with sulfur flotation water. After sizing, the concentration is about 50%, the total cyanide is about 90mg / L, and the pH is about 5. It enters the sulfur flotation process and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com