Colored carbon nitride-based thin film and preparation method thereof

A carbon nitride-based, color technology, applied in chemical instruments and methods, nitrogen compounds, nitrogen and non-metallic compounds, etc., can solve problems such as non-occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

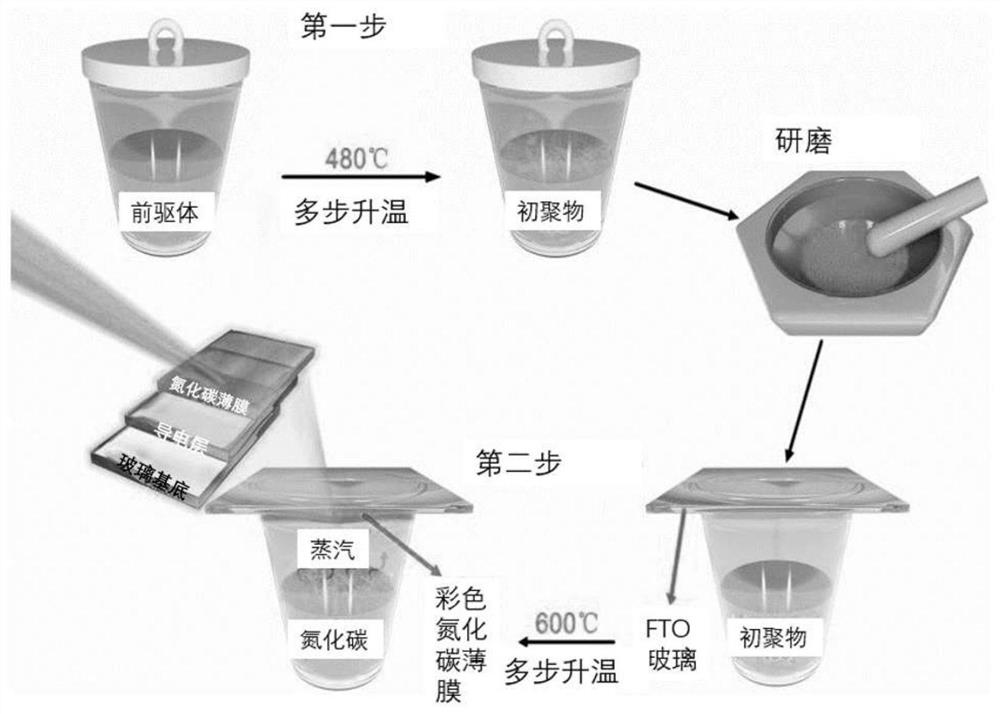

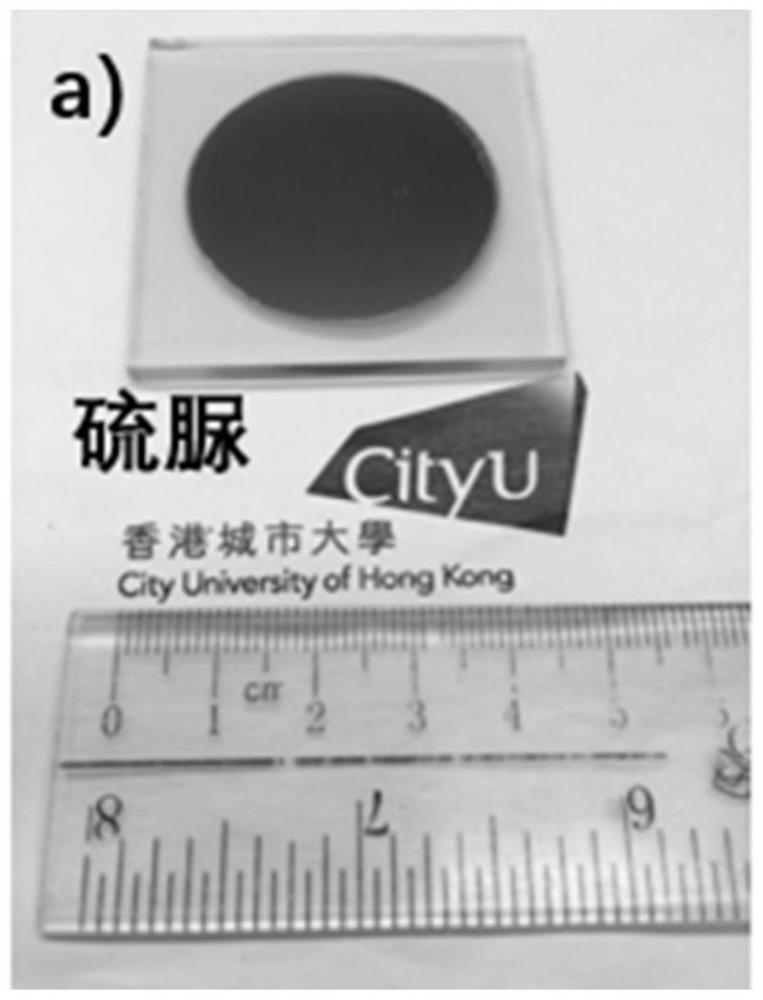

[0055] This embodiment prepares a kind of brown carbon nitride base film, comprises the following steps:

[0056] Put 11.4g of thiourea into the crucible, cover the crucible, and heat the prepolymer in the muffle furnace. The heating steps are r.t.-150°C, 10°C / min; 20min; 390-480℃, 3℃ / min, keep warm for 20min. After cooling, grind the prepolymer and transfer it to the crucible, cover with 5cm×5cm×0.32cm FTO glass, with the conductive surface facing the inside of the crucible, heat in the muffle furnace, the heating step is 0-300°C, 10°C / min; 300-390°C, 1.5°C / min, keep warm for 20min; 390-520°C, 3°C / min, keep warm for 20min; 520-600°C, 3°C / min, keep warm for 20min. After cooling to room temperature, a dark brown carbon nitride film was obtained, such as Figure 2a shown.

[0057] The photoresponse test was performed on an electrochemical workstation, using a three-electrode system, with a platinum sheet as the counter electrode, a silver chloride electrode as the reference e...

Embodiment 2

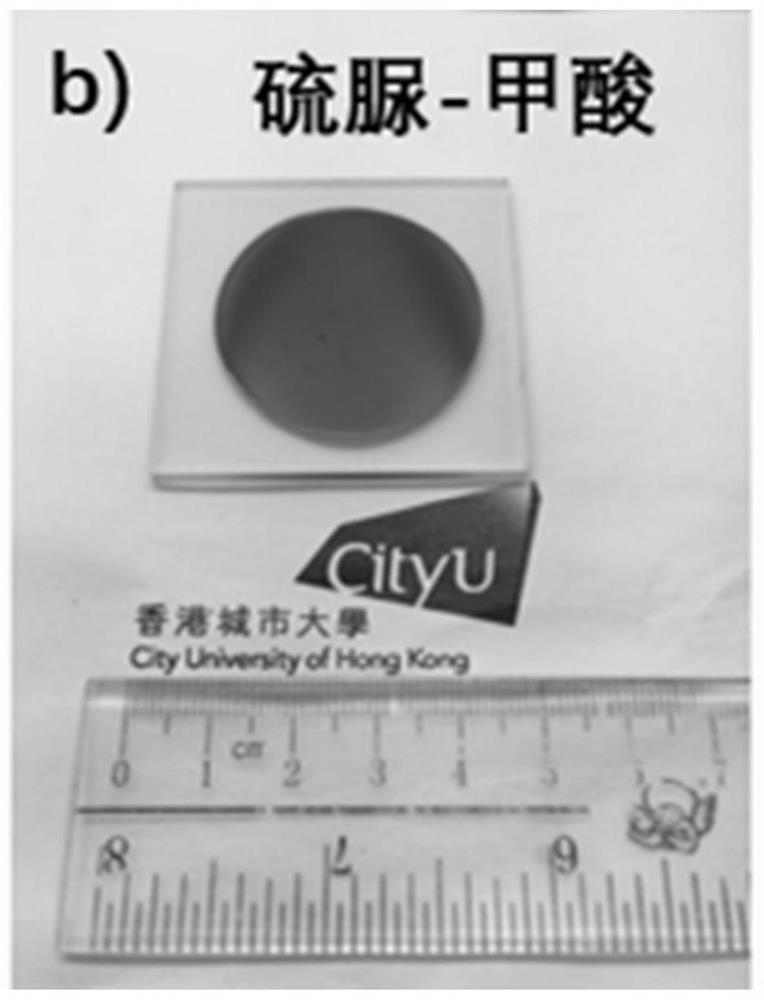

[0060] In this embodiment, a multicolor carbon nitride-based thin film is prepared, which includes the following steps:

[0061] Mix and dissolve 11.4g thiourea, 0.6g formic acid and 100mL water in a crucible, evaporate to dryness at 100°C, cover the crucible and heat in a muffle furnace to obtain a prepolymer. The heating steps are r.t.-150°C, 10°C / min; 150-390°C, 1.5°C / min, keep warm for 20min; 390-480°C, 3°C / min, keep warm for 20min. After cooling, grind the prepolymer and transfer it to a crucible, cover with 5cm×5cm×0.32cm FTO glass, with the conductive surface facing the inside of the crucible, and heat in a muffle furnace, the heating step is 0-300°C, 10°C / min; 300-390°C, 1.5°C / min, keep warm for 20min; 390-520°C, 3°C / min, keep warm for 20min; 520-600°C, 3°C / min, keep warm for 20min. Cool to room temperature to obtain a multi-colored carbon nitride film with a film thickness of 200nm, such as Figure 2b shown.

[0062] The photoresponse current density of this color...

Embodiment 3

[0064] This embodiment prepares a kind of green carbon nitride base film, comprises the following steps:

[0065] Mix and dissolve 11.4g thiourea, 0.6g nitric acid and 100mL water in a crucible, evaporate to dryness at 100°C, cover the crucible and heat in a muffle furnace to obtain a prepolymer. The heating steps are r.t.-150°C, 10°C / min; 150-390°C, 1.5°C / min, keep warm for 20min; 390-480°C, 3°C / min, keep warm for 20min. After cooling, grind the prepolymer and transfer it to a crucible, cover with 5cm×5cm×0.32cm FTO glass, with the conductive surface facing the inside of the crucible, and heat in a muffle furnace, the heating step is 0-300°C, 10°C / min; 300-390°C, 1.5°C / min, keep warm for 20min; 390-520°C, 3°C / min, keep warm for 20min; 520-600°C, 3°C / min, keep warm for 20min. Cool to room temperature to obtain a green carbon nitride film with a film thickness of 200nm, such as Figure 2c shown.

[0066] The photoresponse current density of this color film is 22μA cm -2 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com