Damage monitoring and online maintenance system for thermosetting composite material structure

A technology for composite materials and structural damage, applied in the direction of analyzing materials, using sonic emission technology for material analysis, measuring devices, etc., can solve problems such as being unsuitable for traditional human maintenance, low degree of automation, toxic and harmful equipment, etc., to improve intelligence. degree of safety and reliability, high degree of automation, and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in further detail:

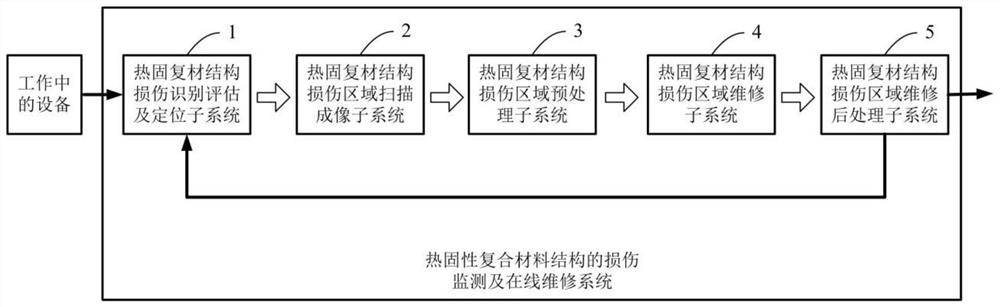

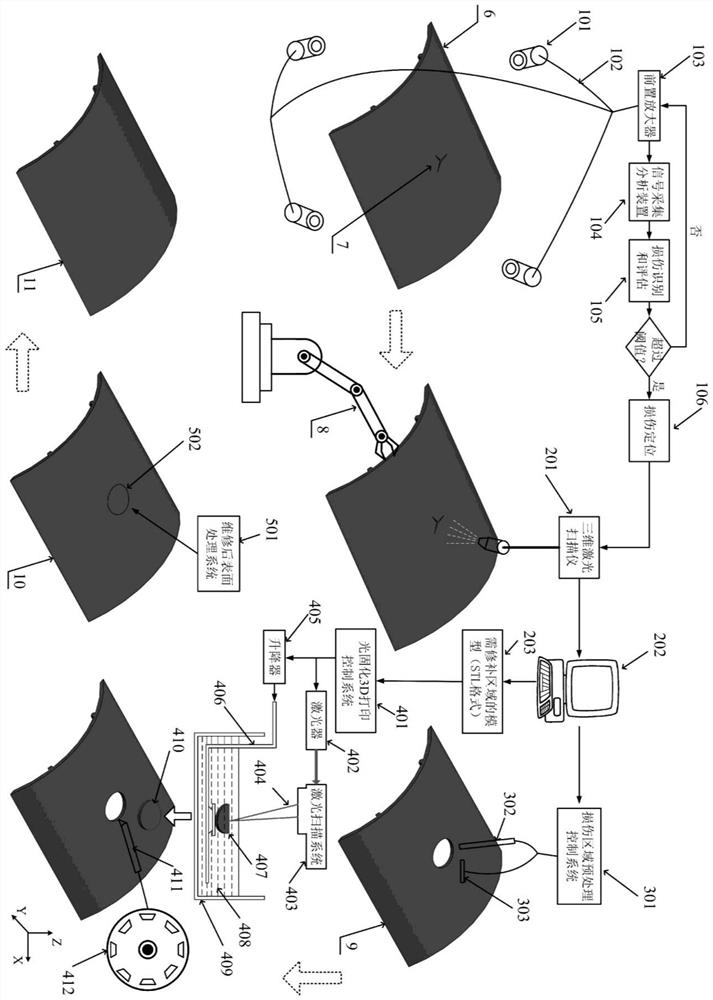

[0025] as attached figure 1 And attached figure 2 As shown, a damage monitoring and on-line maintenance system for a thermosetting composite material structure of the present invention includes: a damage identification, location and evaluation subsystem 1 for a thermosetting composite material structure, an acoustic emission sensor 101, a low-noise signal line 102, and a pre-signal amplifier 103. Signal acquisition and analysis device 104, damage identification and evaluation system 105, damage location system 106; thermosetting composite structure damage area scanning imaging subsystem 2, three-dimensional laser scanner 201, computer 202, model 203 of the area to be repaired; Solid composite material structure damaged area pretreatment subsystem 3, damaged area pretreatment control system 301, surface roughening device 302, cleaning device 303; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com