Method for preparing lipidosome microcapsule long-acting mosquito repellent paste from plant essential oil

A plant essential oil and liposome technology, which is applied in the field of biomedicine, can solve the problems of poor heat sensitivity, poor mosquito repellent effect, easy volatilization of lemon eucalyptus essential oil, etc., and achieve the goal of preventing the volatilization of essential oil, good stability and prolonging mosquito repellent time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

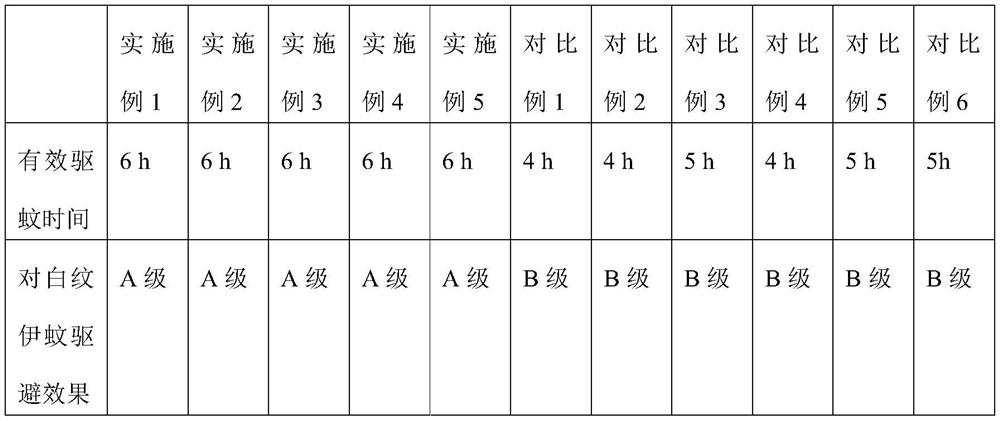

Examples

Embodiment 1

[0029] A kind of method utilizing plant essential oil to prepare liposome microcapsule long-acting mosquito repellent ointment, comprises the steps:

[0030] S1: Dissolve p-menthane-3,8-diol and Java citronella oil in absolute ethanol at a mass ratio of 2:1, and then add sulfosuccinate castor oil with a mass ratio of 1:2 Carry out ultrasonic emulsification with Polyethylene Glycol (600) double laurate emulsifier, be made into core material system, the add-on of described emulsifier is 1.8% of Javanese citronella quality;

[0031] S2: Make a mixture of soybean lecithin, cholesterol, squash gum, propylene glycol alginate, and acrylate redispersible latex powder according to the mass ratio of 5:1:0.3:0.5:0.2, and then add the mixture to the core material system In, stir and mix evenly, the mass ratio of described mixture and core material is 1:1, the mixture that forms adopts decompression distillation to remove ethanol again, can obtain liposome film;

[0032] S3: Ultrasonic di...

Embodiment 2

[0034] A kind of method utilizing plant essential oil to prepare liposome microcapsule long-acting mosquito repellent ointment, comprises the steps:

[0035] S1: Dissolve p-menthane-3,8-diol and Java citronella oil in absolute ethanol at a mass ratio of 2:1, and then add sulfosuccinate castor oil with a mass ratio of 1:1 Carry out ultrasonic emulsification with polyethylene glycol (600) double laurate emulsifier, be made into core material system, the add-on of described emulsifier is 2.5% of Javanese citronella quality;

[0036] S2: Soybean lecithin, cholesterol, squash gum, propylene glycol alginate, ethylene-vinyl acetate redispersible latex powder are formulated into a mixture according to the mass ratio of 8:1.5:0.5:1:0.2, and then the mixture is added to In the core material system, stir and mix evenly, the mass ratio of the mixture and the core material is 1:1.2, and the formed mixture is then decompressed to remove ethanol to obtain the liposome membrane;

[0037] S3:...

Embodiment 3

[0039] A kind of method utilizing plant essential oil to prepare liposome microcapsule long-acting mosquito repellent ointment, comprises the steps:

[0040]S1: Dissolve p-menthane-3,8-diol and Javanese citronella oil in absolute ethanol at a mass ratio of 2:1, and then add sulfosuccinate castor oil with a mass ratio of 1:3 Carry out ultrasonic emulsification with Polyethylene Glycol (600) double laurate emulsifier, be made into core material system, the add-on of described emulsifier is 1.2% of Javanese citronella quality;

[0041] S2: Soybean lecithin, cholesterol, squash gum, propylene glycol alginate, and ethylene-vinyl acetate redispersible latex powder are made into a mixture according to the mass ratio of 10:2:0.1:0.6:0.3, and then the mixture is added to In the core material system, stirring and mixing are uniform, the mass ratio of the mixture and the core material is 1:1.5, stirring and mixing are uniform, and the formed mixture is then decompressed to remove ethanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com