MTBE device methanol recovery system and process

A methanol recovery and methanol technology, applied in the chemical industry, sustainable manufacturing/processing, distillation and separation, etc., can solve the problems of acid corrosion, packing or sieve clogging, corrosion leakage, etc. in the methanol recovery system, so as to reduce equipment corrosion and leakage, Compact structure and significant social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The features and principles of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

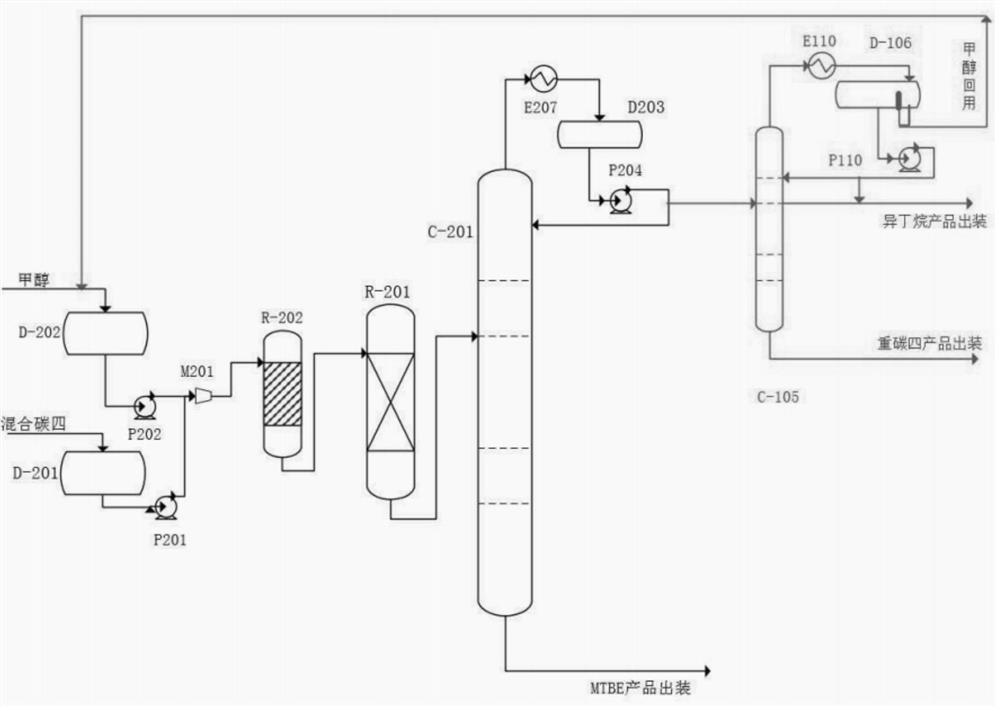

[0027] Such as figure 1 As shown, the methanol recovery system of this kind of MTBE unit includes a methanol raw material tank and a carbon four raw material tank connected to a feed mixer. The feed mixer is connected to a catalytic distillation tower through a purifier, and the top of the catalytic distillation tower is refluxed with the catalytic distillation Tank connection, the bottom is connected to the MTBE product tank, the catalytic distillation reflux tank is connected to the reflux of the catalytic distillation tower through the pipeline, and the C4 tower is connected through the pipeline. One way is connected to the isobutane product tank, the C4 tower reflux tank is connected to the C4 tower refl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com