Liquid setting accelerator as well as preparation method and application thereof

A technology of accelerator and liquid, which is applied in the field of liquid accelerator and its preparation, can solve problems such as difficult to configure accelerator, unstable solution state, and low solubility of aluminum sulfate, so as to reduce negative reactions, low raw material cost, The effect of low alkali content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

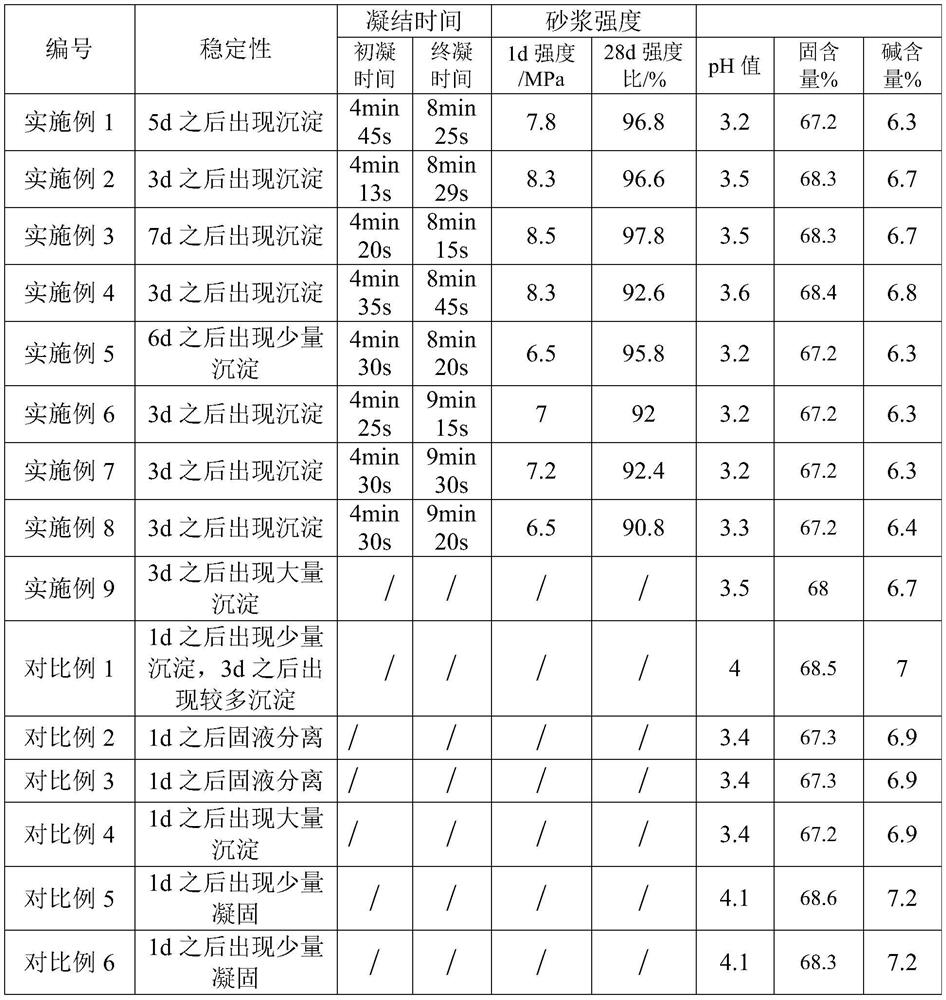

Examples

Embodiment 1

[0059] 1. Weigh sodium fluoride, sodium fluorosilicate, magnesium fluorosilicate, water, and sodium edetate according to the ratio in Table 1 and mix them into a three-necked flask, heat to 60-100°C, and stir thoroughly for 30 -50 minutes until the solution state is stable, wherein the mass ratio of the sum of sodium fluorosilicate and magnesium fluorosilicate to the complexing agent is 1.1:1.

[0060] 2. Weigh aluminum sulfate and calcium oxide according to the ratio in Table 1 and add them to a three-neck flask, heat to 60-100°C, and stir thoroughly for 40-100 minutes until the solution is stable.

[0061] 3. Weigh diethanolamine and triethanolamine according to the ratio in Table 1 (the mass ratio of diethanolamine and triethanolamine is 10:3) into a three-necked flask, heat to 60-100°C, and stir thoroughly for 30-60 minutes until The solution state is stable, and the liquid quick-setting agent is obtained.

Embodiment 2

[0063] 1. Weigh sodium fluoride, sodium fluorosilicate, magnesium fluorosilicate, water, and sodium edetate according to the ratio in Table 1 and mix them into a three-necked flask, heat to 60-100°C, and stir thoroughly for 30 -50 minutes, until the solution state is stable, wherein the mass ratio of the sum of sodium fluorosilicate and magnesium fluorosilicate to the complexing agent is 1.5:1.

[0064] 2. Weigh aluminum sulfate and calcium oxide according to the ratio in Table 1 and add them to a three-neck flask, heat to 60-100°C, and stir thoroughly for 40-100 minutes until the solution is stable.

[0065] 3. Weigh diethanolamine and triethanolamine according to the ratio in Table 1 (the mass ratio of diethanolamine and triethanolamine is 10:3) into a three-necked flask, heat to 60-100°C, and stir thoroughly for 30-60 minutes until The solution state is stable, and the liquid quick-setting agent is obtained.

Embodiment 3

[0067] 1. Weigh sodium fluoride, sodium fluorosilicate, magnesium fluorosilicate, water, and sodium edetate according to the ratio in Table 1 and mix them into a three-necked flask, heat to 60-80°C, and stir thoroughly for 30 -70 minutes until the solution state is stable, wherein the mass ratio of the sum of sodium fluorosilicate and magnesium fluorosilicate to the complexing agent is 1:1.

[0068] 2. Weigh aluminum sulfate and calcium oxide according to the ratio in Table 1 and add them into a three-neck flask, heat to 60-80°C, and stir thoroughly for 40-120 minutes until the solution is stable.

[0069] 3. Weigh diethanolamine and triethanolamine according to the ratio in Table 1 (the mass ratio of diethanolamine and triethanolamine is 10:3) into a three-necked flask, heat to 60-80°C, and stir thoroughly for 30-80 minutes until The solution state is stable, and the liquid quick-setting agent is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com