Anti-drag material for fine pressure-controlled well cementation and anti-drag cement paste

A drag-reducing water and well cementing technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of small wellhead back pressure compensation space, large cement slurry annular friction resistance, and inability to achieve fine grout injection stage. Problems such as pressure control, to achieve the effect of improved rheological properties, stable thickening performance, and good sedimentation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

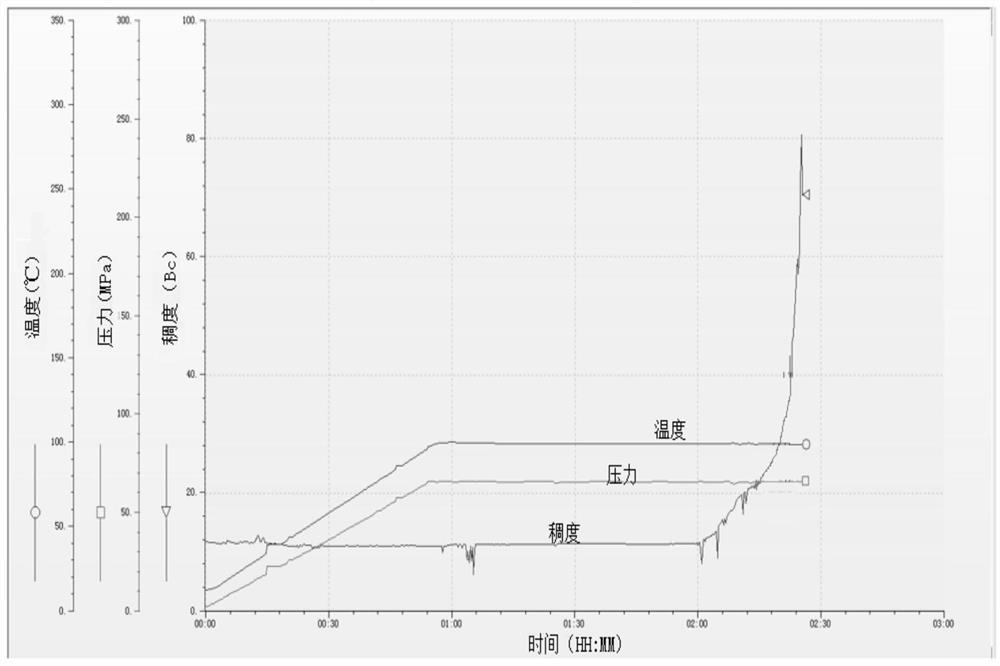

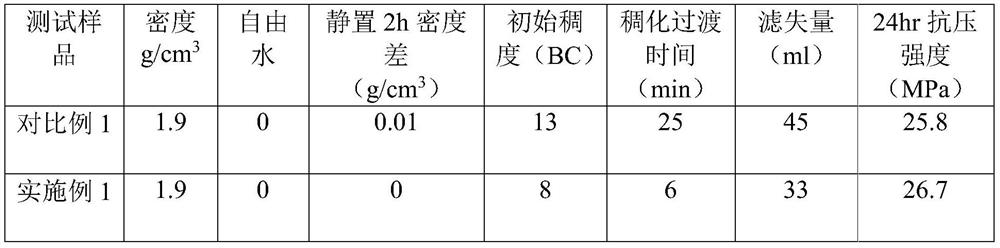

Embodiment 1

[0061] The drag-reducing cement slurry system (1.90g / cm 3 ) is composed as follows (parts by mass):

[0062] 100 parts of G grade oil well cement; 46 parts of fresh water; 10 parts of drag reducing material; 1.5 parts of suspension stabilizer; 3 parts of fluid loss reducer; 0.5 part of retarder; 0.6 part of defoamer.

[0063] Among them, the drag reducing material is composed of drag reducing agent, drag reducing particles, polymer active agent, sodium sulfamate and phosphoric acid ester. The content of each component in 10 parts of drag reducing material is as follows: 0.9 parts of alkali drag reducing agent, 0.9 parts of drag reducing particles, 3.5 parts, 4.4 parts of polymer active agent, 0.9 part of sodium sulfamate, 0.3 part of phosphoric acid ester;

[0064] Among them, the drag reducing agent is sulfonated ketone aldehyde condensation polymer, and the material of drag reducing particles is spherical trimanganese tetroxide, which consists of 400 mesh (low mesh) spheric...

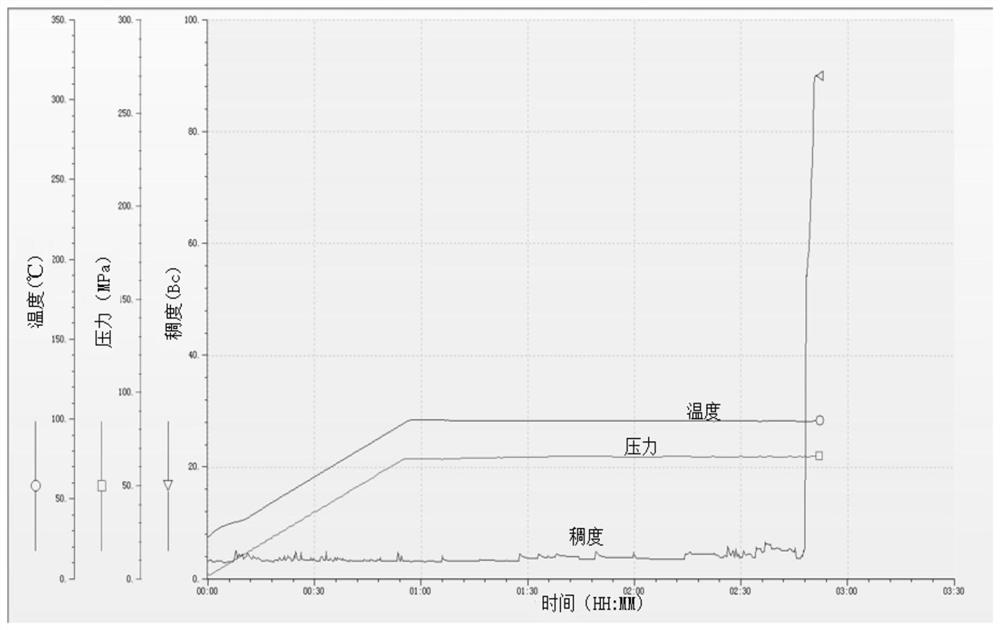

Embodiment 2

[0088] The drag-reducing cement slurry system (2.00g / cm 3 ) is composed as follows:

[0089] 100 parts of G grade oil well cement; 46 parts of fresh water; 20 parts of weighting agent; 12 parts of drag reducing material; 2 parts of suspension stabilizer;

[0090] Among them, the drag reducing material is composed of drag reducing agent, drag reducing particles, polymer active agent, sodium sulfamate and phosphoric acid ester. The content of each component in 12 parts of drag reducing material is as follows: 1.08 parts of alkali drag reducing agent, 1.08 parts of drag reducing particles, 4.2 parts, 5.28 parts of polymer active agent, 1.08 parts of sodium sulfamate, 0.36 parts of phosphoric acid ester;

[0091] Among them, the drag reducing agent is sulfonated ketone aldehyde condensation polymer, and the material of drag reducing particles is spherical trimanganese tetroxide, which consists of 400 mesh (low mesh) spherical solid particles and 800 mesh (high mesh) balls. Type ...

Embodiment 3

[0094] The drag-reducing cement slurry system (2.1g / cm 3 ) is composed as follows:

[0095] 100 parts of G grade oil well cement; 52 parts of fresh water; 50 parts of weighting material; 15 parts of drag reducing material; 2 parts of suspension stabilizer;

[0096] Among them, the drag reducing material is composed of drag reducing agent, drag reducing particles, polymer active agent, sodium sulfamate and phosphoric acid ester. The content of each component in 15 parts of drag reducing material is as follows: 1.35 parts of alkali drag reducing agent, 1.35 parts of drag reducing particles, 5.25 parts, 6.6 parts of polymer active agent, 1.35 parts of sodium sulfamate, 0.45 parts of phosphoric acid ester;

[0097] Among them, the drag reducing agent is sulfonated ketone aldehyde condensation polymer, and the material of drag reducing particles is spherical trimanganese tetroxide, which consists of 400 mesh (low mesh) spherical solid particles and 800 mesh (high mesh) balls. Typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com