High-strength and high-thermal-conductivity polyimide film and preparation method and cutting equipment thereof

A polyimide film, high thermal conductivity technology, used in flat products, other household appliances, applications, etc., can solve the problems of fixed structure, the strength and thermal conductivity of polyimide film cannot meet product requirements, and the quality of use is reduced. , to achieve the effect of convenient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A high-strength and high-thermal-conductivity polyimide film, the high-strength and high-thermal-conduction polyimide film is composed of the following raw materials in parts by mass: 65 parts of 3,3',4,4'-biphenyltetracarboxylic dianhydride , 48 parts of p-phenylenediamine, 5.8 parts of flake graphite and 3.6 parts of nanocrystalline diamond.

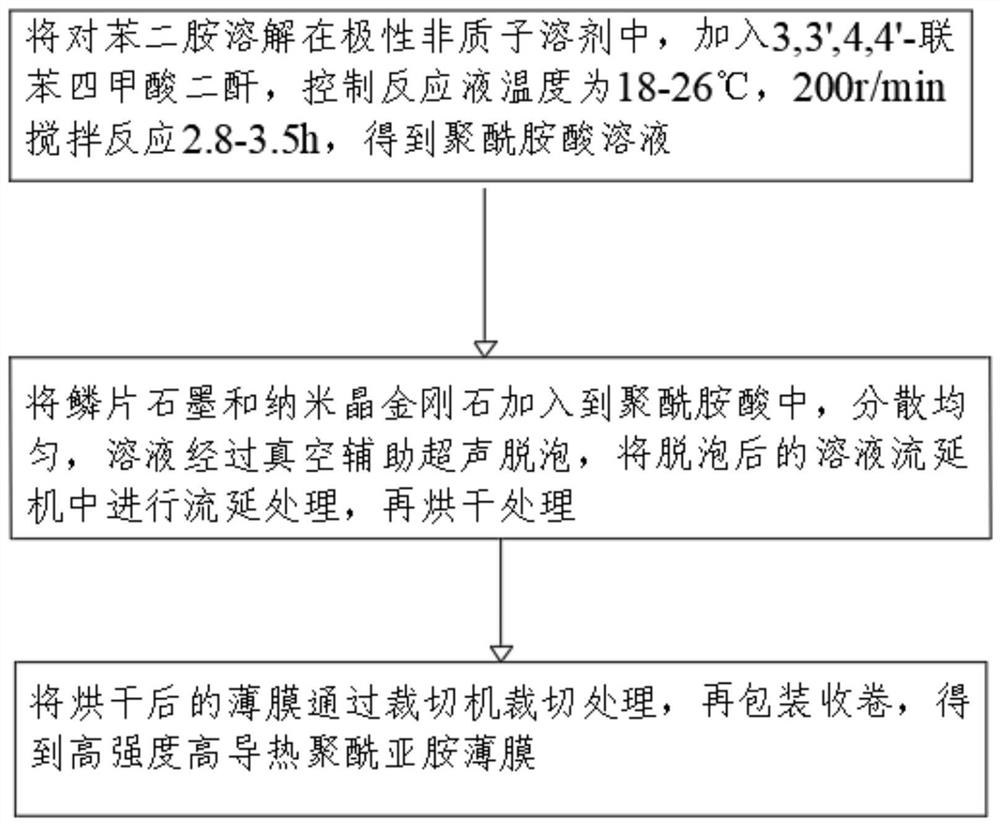

[0038]A preparation method of a high-strength and high-thermal-conductivity polyimide film, the steps of the preparation method are as follows:

[0039] Step 1. Dissolve p-phenylenediamine in a polar aprotic solvent, add 3,3',4,4'-biphenyltetracarboxylic dianhydride, control the temperature of the reaction solution at 26°C, and stir at 200r / min for 2.8h , to obtain a polyamic acid solution;

[0040] Step 2: adding flake graphite and nanocrystalline diamond into polyamic acid, dispersing evenly, the solution undergoes vacuum-assisted ultrasonic degassing, casting the defoamed solution in a casting machine, and then drying;

[0...

Embodiment 2

[0043] A high-strength and high-thermal conductivity polyimide film, the high-strength and high thermal conductivity polyimide film is composed of the following raw materials in parts by mass: 45 parts of 3,3',4,4'-biphenyltetracarboxylic dianhydride , 42 parts of p-phenylenediamine, 5.5 parts of flake graphite and 4.2 parts of nanocrystalline diamond.

[0044] A preparation method of a high-strength and high-thermal-conductivity polyimide film, the steps of the preparation method are as follows:

[0045] Step 1. Dissolve p-phenylenediamine in a polar aprotic solvent, add 3,3',4,4'-biphenyltetracarboxylic dianhydride, control the temperature of the reaction solution at 24°C, and stir at 200r / min for 3.5h , to obtain a polyamic acid solution;

[0046] Step 2: adding flake graphite and nanocrystalline diamond into polyamic acid, dispersing evenly, the solution undergoes vacuum-assisted ultrasonic degassing, casting the defoamed solution in a casting machine, and then drying;

...

Embodiment 3

[0049] A high-strength and high-thermal conductivity polyimide film, the high-strength and high thermal conductivity polyimide film is composed of the following raw materials in parts by mass: 45 parts of 3,3',4,4'-biphenyltetracarboxylic dianhydride , 42 parts of p-phenylenediamine, 6.2 parts of flake graphite and 4.8 parts of nanocrystalline diamond.

[0050] A preparation method of a high-strength and high-thermal-conductivity polyimide film, the steps of the preparation method are as follows:

[0051] Step 1. Dissolve p-phenylenediamine in a polar aprotic solvent, add 3,3',4,4'-biphenyltetracarboxylic dianhydride, control the temperature of the reaction solution at 18°C, and stir at 200r / min for 3.2h , to obtain a polyamic acid solution;

[0052] Step 2: adding flake graphite and nanocrystalline diamond into polyamic acid, dispersing evenly, the solution undergoes vacuum-assisted ultrasonic degassing, casting the defoamed solution in a casting machine, and then drying;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com