Colored ink composition for dyeing surface of high-cleanliness material

A color ink and surface dyeing technology, applied in ink, household utensils, applications, etc., can solve the problems of surface coloring, cost and process difficulties, and complicated process of materials with high cleanliness, and achieve flexible color changes, rich colors, and easy operation The effect of simple process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

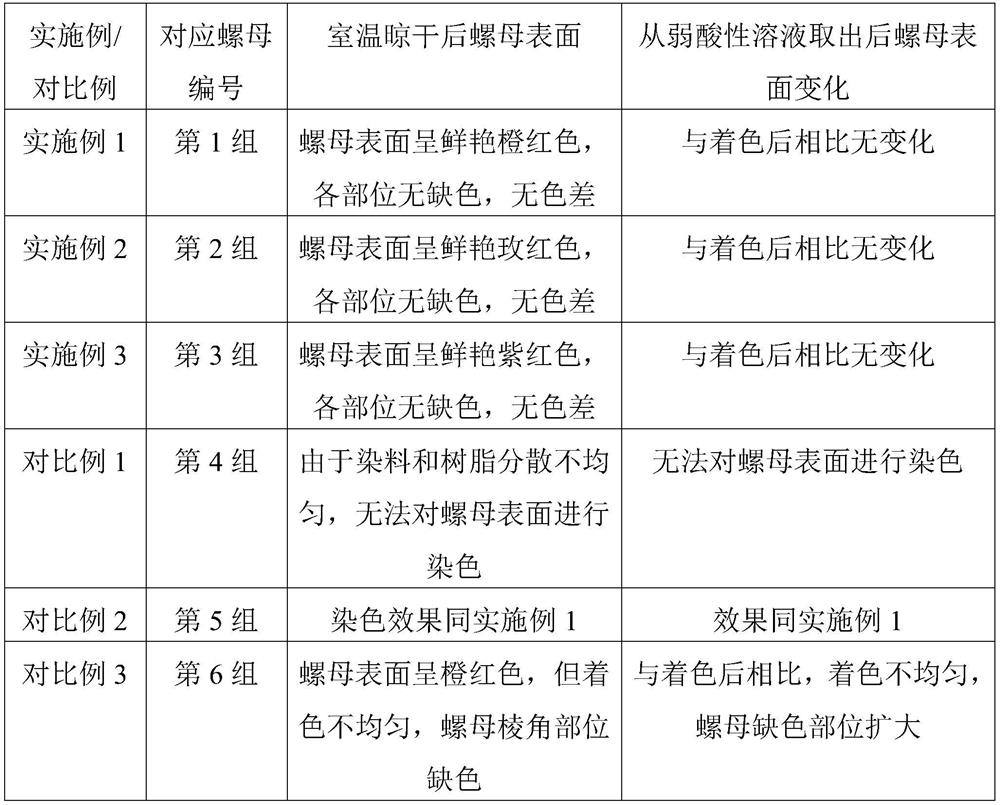

Examples

Embodiment 1

[0020] Orange-red color ink composition: 2,18,8,5,5 parts of weight parts, 2.5 parts of solvent yellow T, 17 parts of ethylene glycol, 45 n-butanol, 12 parts of polyvinyl alcohol, 19 parts of propanol And the leveling agent is 410 parts.

[0021] The method of preparing the orange-red color ink composition includes the following steps: 1) Weigh the solvent red 218 and the solvent yellow T, adding one-half of the amount of ethylene glycol and one-half of the n-butanol mixed after mixing. Further, the mixture a; 2) is referred to as a polyvinyl alcohol resin, adding the addition of one-half of the amount of ethylene glycol and one-half of n-butanol, pure powder, stirred dissolved, mixture B; 3) After mixing with the mixture B, the glycerol and level of Deli Di height 410 were slowly added thereto, and the color ink composition was uniformly obtained.

Embodiment 2

[0023] Rose red color ink composition: B2 parts of a weight of the weight, 50 parts of n-propanol, 25 parts of positivellicol, 6 parts of ethylene glycol, 6 urea, 2 urea, leveling agent BYK307 5 Part.

[0024] The method of preparing the rose-red color ink composition includes the following steps: 1) refer to the basic rose red B, adding one-half of the amount of n-propol and one-half of the amount of ethylene glycol monobutyl ether to stir after mixing Honen, obtaining mixture a; 2) weighing the urea resin, adding the remaining amount of n-propanol and the amount of ethylene glycol monobutyl ether, pure powder is stirred, and the mixture B; 3) After mixing the mixture A with the mixture B, urea and BYK307 were slowly added, and the color ink composition was uniformly obtained.

Embodiment 3

[0026] Purple Colored Ink Composition: Taking a mass of 10 parts by weight, a basic rose red B6, 15 parts of ethanol, 15 parts of diethylene glycol butyl ether, 20 n-butanol 10 parts. 7 parts of epoxy resin, 20 sorbitol.

[0027] The preparation method of the purple color ink composition includes the following steps: 1) Weigh the purple red O and alkaline rose red B, add one-half of ethanol, one-half of diethylene glycol butyl ether and After mixing the n-butanol mixed, stir well, resulting in mixture a; 2), the epoxy resin is obtained, adding the remaining amount of ethanol, one-half of diethylene glycol butyl ether and After one-half of the n-butanol, pure powder was stirred, and the mixture B; 3) was mixed with the mixture A and the sorbitol was slowly added thereto, and the colored ink composition was uniformly obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com