Pectin graft copolymer as well as preparation method and application thereof

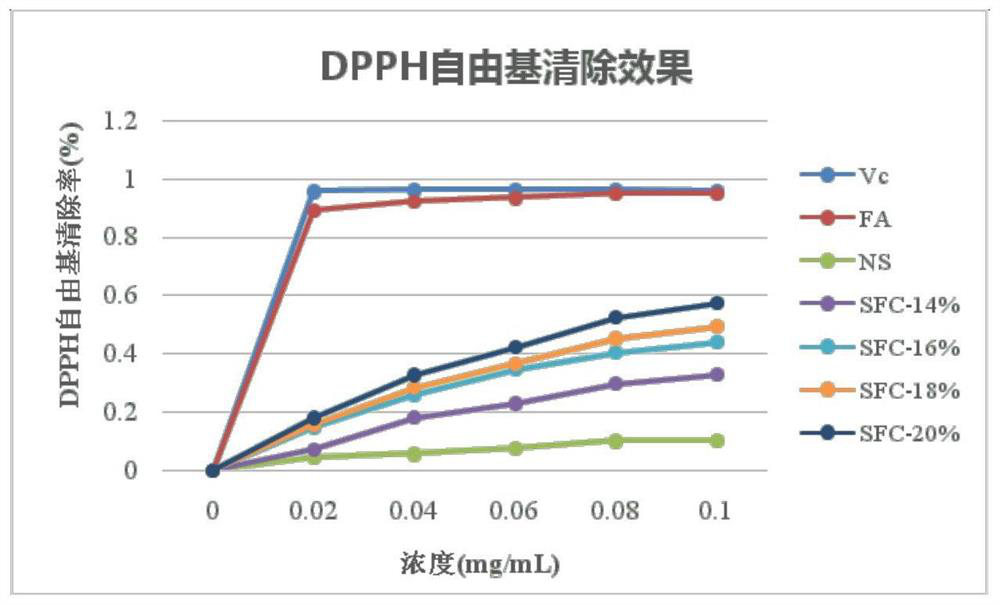

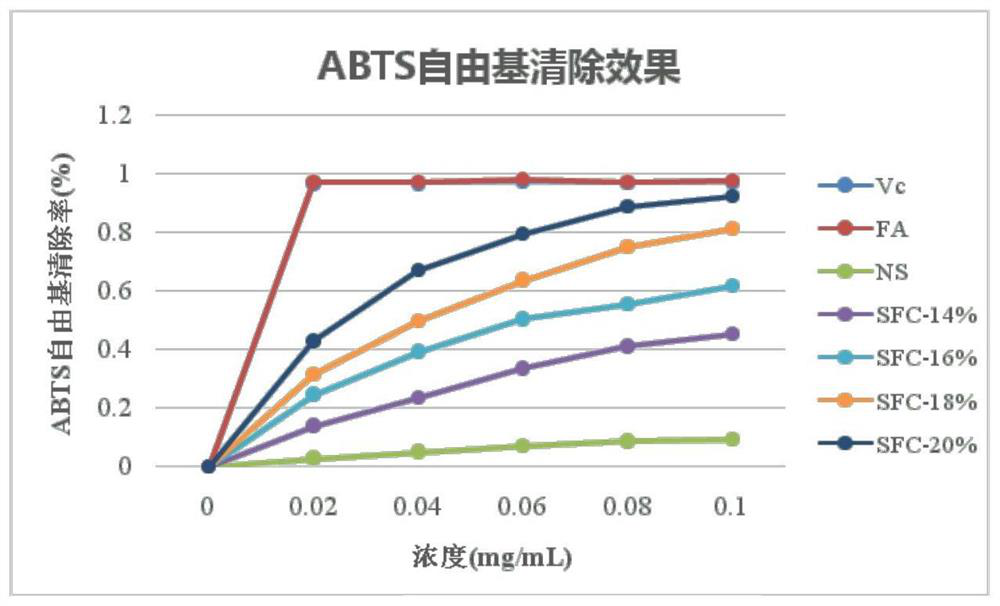

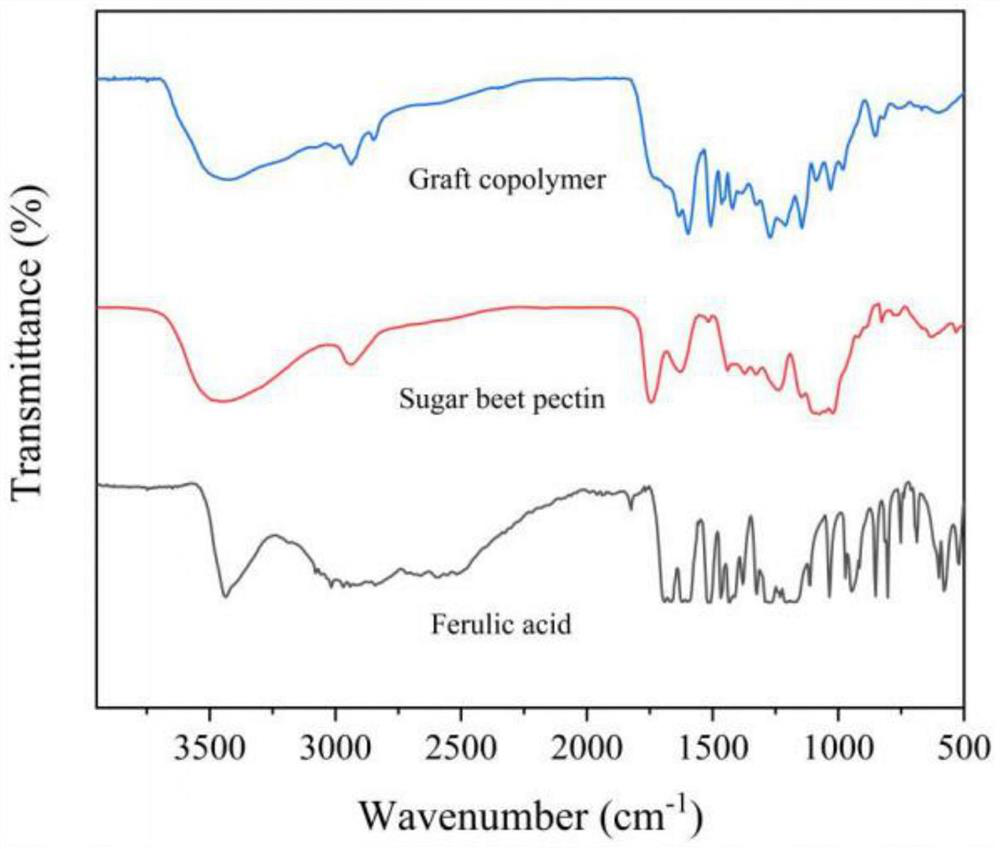

A graft copolymer and a technology of copolymerization reaction are applied in the field of pectin graft copolymer and its preparation, and can solve the problems of unsatisfactory oxidation resistance and thermal stability of natural pectin, unable to meet the actual needs in the field of food chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation of embodiment 1 pectin graft copolymer (SFC-14%)

[0039] 1) Add 0.5g of beet pectin powder to 45mL of 50mM phosphate buffer (pH 7.5), and stir magnetically at 20°C for 8 hours to fully dissolve the beet pectin;

[0040] 2) 5 mL of 1.0% (w / v) ferulic acid-methanol solution was added to the pectin solution in step 1), and the resulting mixed solution was magnetically stirred at 20° C. and 500 rpm for 15 min;

[0041] 3) 100 μL of laccase was added to the mixed solution in step 2) to initiate the reaction, and the resulting mixed solution was magnetically stirred at 20° C. and 500 rpm for 15 minutes;

[0042] 4) React the mixed system obtained in step 3) in a constant temperature shaking water bath at 40°C and 120 rpm for 1 hour;

[0043] 5) After the reaction, add 150 mL of absolute ethanol to the reaction solution in step 4) to terminate the reaction, and the resulting mixed liquid is filtered twice with a vacuum pump;

[0044] 6) Rotate evaporate the ...

Embodiment 2

[0047] The preparation of embodiment 2 pectin graft copolymer (SFC-16%)

[0048] 1) Add 0.5g of beet pectin powder to 45mL of 50mM phosphate buffer (pH 7.5), and stir magnetically at 20°C for 8 hours to fully dissolve the beet pectin;

[0049] 2) 5 mL of 2.0% (w / v) ferulic acid-methanol solution was added to the pectin solution in step 1), and the resulting mixed solution was magnetically stirred at 20° C. and 500 rpm for 15 min;

[0050] 3) 150 μL of laccase was added to the mixed solution in step 2) to initiate the reaction, and the resulting mixed solution was magnetically stirred at 20° C. and 500 rpm for 15 minutes;

[0051] 4) React the mixed system obtained in step 3) in a constant temperature shaking water bath at 30°C and 120rpm for 4h;

[0052] 5) After the reaction, add 150 mL of absolute ethanol to the reaction solution in step 4) to terminate the reaction, and the resulting mixed liquid is filtered twice with a vacuum pump;

[0053] 6) Rotate evaporate the filtr...

Embodiment 3

[0056] The preparation of embodiment 3 pectin graft copolymers (SFC-18%)

[0057] 1) Add 0.5g of beet pectin powder to 45mL of 50mM phosphate buffer (pH 7.5), and stir magnetically at 20°C for 8 hours to fully dissolve the beet pectin;

[0058] 2) 5 mL of 1.0% (w / v) ferulic acid-methanol solution was added to the pectin solution in step 1), and the resulting mixed solution was magnetically stirred at 20° C. and 500 rpm for 15 min;

[0059] 3) 50 μL of laccase was added to the mixed solution in step 2) to initiate the reaction, and the resulting mixed solution was magnetically stirred at 20° C. and 500 rpm for 15 minutes;

[0060] 4) React the mixed system obtained in step 3) in a constant temperature shaking water bath at 30°C and 120rpm for 3h;

[0061] 5) After the reaction, add 150 mL of absolute ethanol to the reaction solution in step 4) to terminate the reaction, and the resulting mixed liquid is filtered twice with a vacuum pump;

[0062] 6) Rotate evaporate the filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com