Cobalt ferrite magnetic nanoparticle filled strain rate sensitive composite material and method

A technology of magnetic nanoparticles and composite materials, which is applied in the preparation of cobalt ferrite magnetic nanoparticles filled strain rate sensitive composite materials, and in the field of cobalt ferrite magnetic nanoparticles filled strain rate sensitive composite materials, which can solve the problem of CFO magnetic nanoparticles Problems such as uneven reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

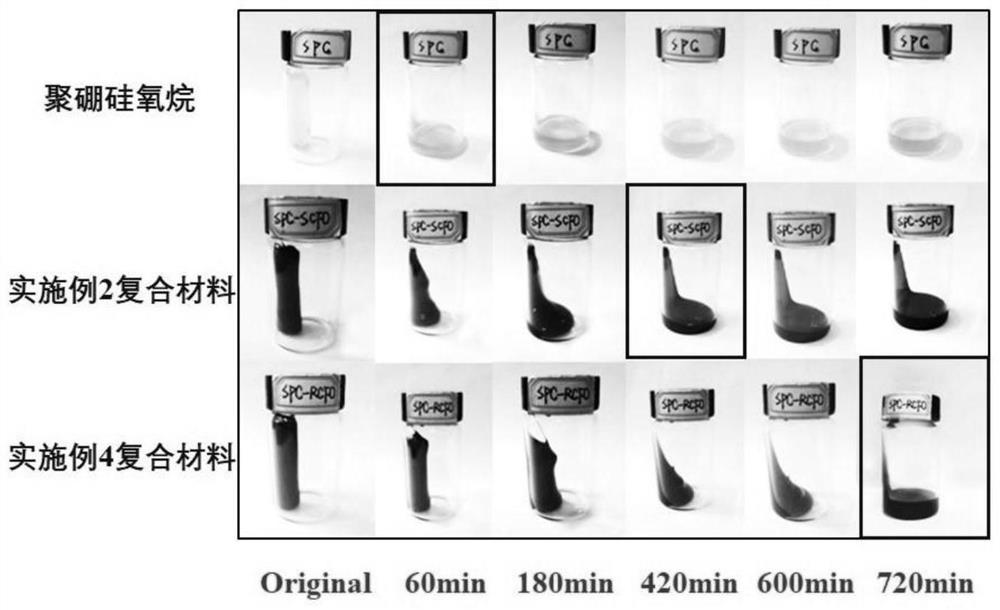

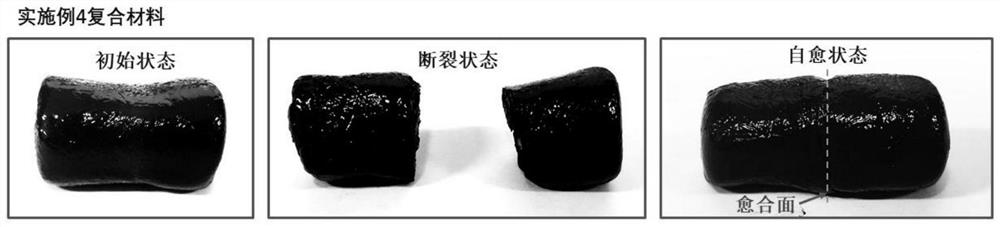

[0042] The invention provides a method for preparing a strain rate-sensitive composite material filled with cobalt ferrite (CFO) magnetic nanoparticles, which is specifically implemented according to the following steps:

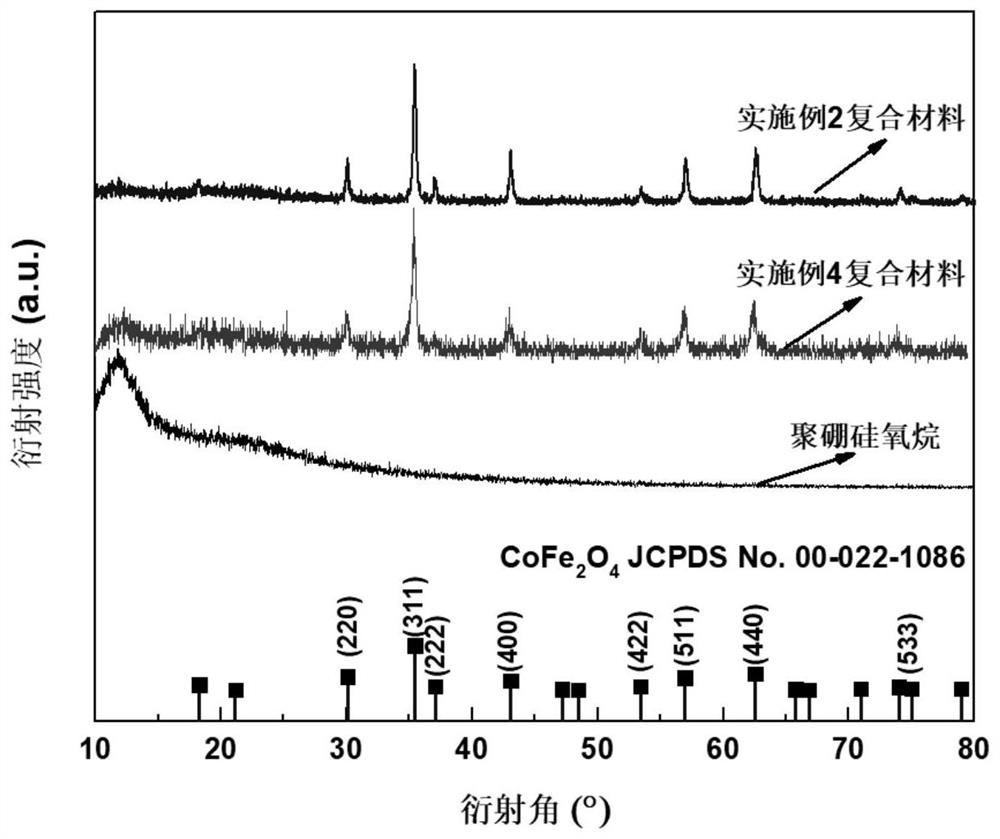

[0043] Step 1. Preparation of CoFe 2 o 4 magnetic nanoparticles

[0044] In step 1, CoFe 2 o 4 Magnetic nanoparticles for CoFe 2 o 4 Nanospheres (SCFO) or CoFe 2 o4 nanorods (RCFO);

[0045] A: Preparation of CoFe 2 o 4 The method of magnetic nanoparticles (SCFO) is as follows:

[0046] Step S1, weighing raw materials according to the following molar mass ratio: FeCl 3 ·6H 2 O: CoCl 2 ·6H 2 O: CH 3 COONa·3H 2 O: polyethylene glycol = 2.5:5:25~30:40~50;

[0047] Step S2, FeCl 3 ·6H 2 O and CoCl 2 ·6H 2 O is mixed with ethylene glycol to obtain a mixed solution A; wherein, 12.5 mmol of FeCl is required for every 100 mL of ethylene glycol 3 ·6H 2 O;

[0048] Step S3, continuously stir the mixed solution A at 50-60°C for 30-60min, and mix ...

Embodiment 1

[0064] A method for preparing a strain rate sensitive composite material filled with cobalt ferrite magnetic nanoparticles, specifically implemented according to the following steps:

[0065] Step 1. Preparation of CoFe 2 o 4 magnetic nanoparticles

[0066] In step 1, CoFe 2 o 4 Magnetic nanoparticles for CoFe 2 o 4 Nanospheres to prepare CoFe 2 o 4 The method of nanospheres is as follows:

[0067] Step S1, weighing raw materials according to the following molar mass ratio: FeCl 3 ·6H 2 O: CoCl 2 ·6H 2 O: CH 3 COONa·3H 2 O: polyethylene glycol = 2.5:5:25:40;

[0068] Step S2, FeCl 3 ·6H 2 O and CoCl 2 ·6H 2 O is mixed with ethylene glycol to obtain a mixed solution A; wherein, 12.5 mmol of FeCl is required for every 100 mL of ethylene glycol 3 ·6H 2 O;

[0069] Step S3, continuously stir the mixed solution A at 50°C for 30min, and mix CH 3 COONa·3H 2 O and polyethylene glycol (PEG-4000) are added in mixed solution A to obtain mixed solution B;

[0070] ...

Embodiment 2

[0078] Step 1. Preparation of CoFe 2 o 4 magnetic nanoparticles

[0079] In step 1, CoFe 2 o 4 Magnetic nanoparticles for CoFe 2 o 4 Nanospheres to prepare CoFe 2 o 4 The method of nanospheres is as follows:

[0080] Step S1, weighing raw materials according to the following molar mass ratio: FeCl 3 ·6H 2 O: CoCl 2 ·6H 2 O: CH 3 COONa·3H 2 O: polyethylene glycol = 2.5:5:26:45;

[0081] Step S2, FeCl 3 ·6H 2 O and CoCl 2 ·6H 2 O is mixed with ethylene glycol to obtain a mixed solution A; wherein, 12.5 mmol of FeCl is required for every 100 mL of ethylene glycol 3 ·6H 2 O;

[0082] Step S3, continuously stir the mixed solution A at 60°C for 30min, and mix CH 3 COONa·3H 2 O and Polyethylene Glycol are added in the mixed solution A to obtain the mixed solution B;

[0083] Step S4, pour the mixed solution B into an autoclave lined with PPL, and heat at 210° C. for 9 hours to obtain a mixed solution C, cool to room temperature, suction filter and wash the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com