Preparation method and application of a high-entropy alloy for passive heavy-duty bulletproof armor

A high-entropy alloy and heavy-duty technology, which is applied in the field of high-entropy alloys, can solve the problems of poor protection of high-speed warheads, can not be used to protect heavy weapons, and is easy to split into many fragments, so as to achieve uniform structure and mechanical properties and good plasticity Moldability, ease of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method for high-entropy alloys for passive heavy-duty bulletproof armor, comprising the steps of:

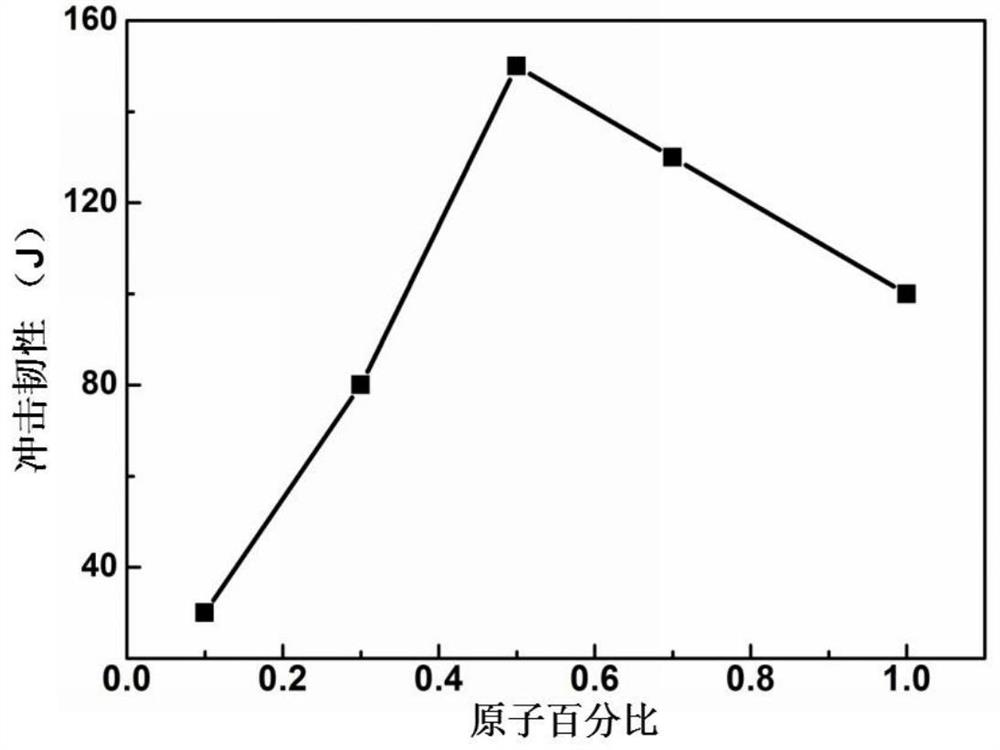

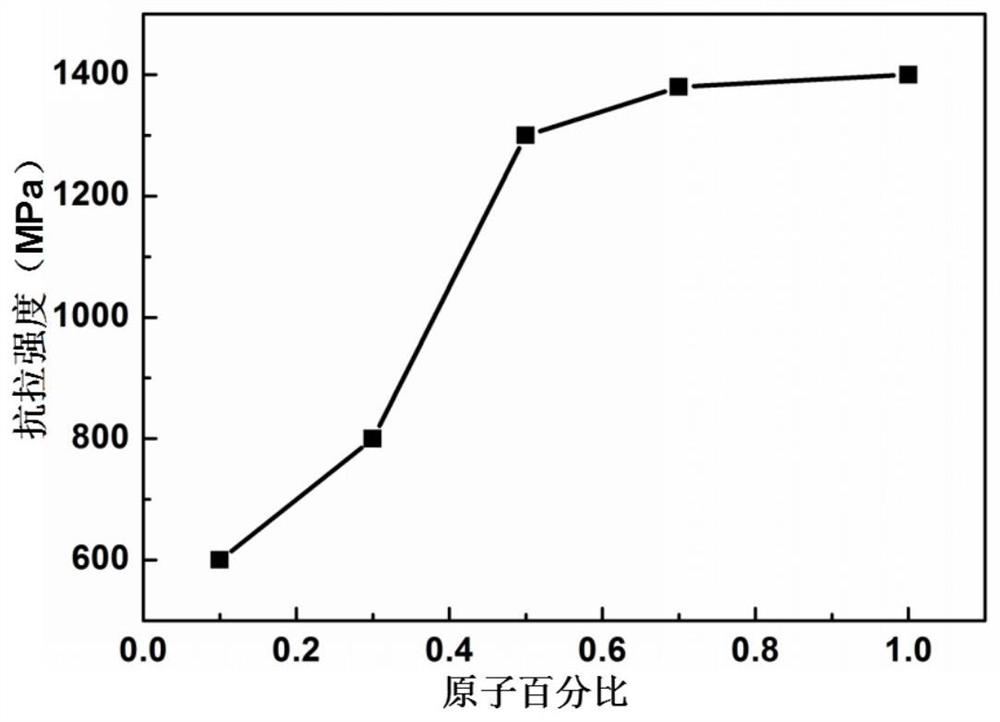

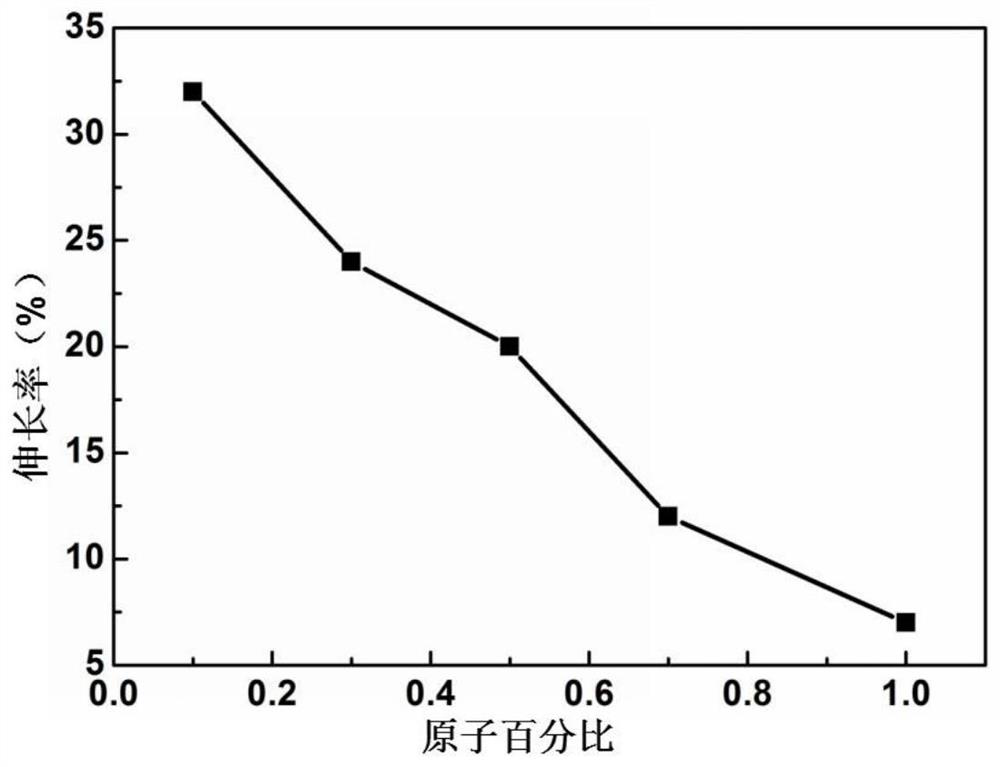

[0030] (1) Powder mixing: according to the atomic percentage of the high-entropy alloy 1:1:1:1:0.1, five elemental powders of cobalt, chromium, iron, nickel, and boron with a purity of 99.9% were mixed to obtain a mixed powder;

[0031] (2) Melting: Fill the above mixed metal powder into the crucible melting furnace of the spray deposition equipment and melt it at 1500°C to obtain molten metal;

[0032] (3) Lubricant coating: the inside of the rectangular mold on the workbench in the deposition chamber is coated with a water-based colloidal graphite lubricant, and after drying, the high-purity argon gas with a flow rate of 100 sccm is fed to form a protective atmosphere;

[0033] (4) Deposition: Fill the above-mentioned molten metal into the molten metal bag and pass high-purity argon gas with a pressure of 1.2MPa. The molten metal is atomized through a nozz...

Embodiment 2

[0040] A preparation method for high-entropy alloys for passive heavy-duty bulletproof armor, comprising the steps of:

[0041](1) Powder blending: five elemental powders of cobalt, chromium, iron, nickel and boron with a purity of 99.9% were mixed according to the atomic percentage of the high-entropy alloy 1:1:1:1:0.3 to obtain a mixed powder;

[0042] (2) Melting: Fill the above mixed metal powder into the crucible melting furnace of the spray deposition equipment and melt it at 1600°C to obtain molten metal;

[0043] (3) Lubricant coating: DFY-1 type grease-based coating lubricant is coated inside the rectangular mold on the workbench in the deposition chamber, and after drying, the high-purity argon gas with a flow rate of 80 sccm is formed to form a protective atmosphere;

[0044] (4) Deposition: Fill the above-mentioned molten metal into the molten metal bag and pass high-purity argon gas with a pressure of 1.0MPa. The molten metal is atomized through a nozzle with a di...

Embodiment 3

[0051] A preparation method for high-entropy alloys for passive heavy-duty bulletproof armor, comprising the steps of:

[0052] (1) Powder blending: five elemental powders of cobalt, chromium, iron, nickel and boron with a purity of 99.9% were mixed according to the atomic percentage of the high-entropy alloy 1:1:1:1:0.5 to obtain a mixed powder;

[0053] (2) Melting: Fill the above mixed metal powder into the crucible melting furnace of the spray deposition equipment and melt it at 1550°C to obtain molten metal;

[0054] (3) Lubricant coating: the inside of the rectangular mold on the workbench in the deposition chamber is coated with a water-based colloidal graphite lubricant, and after drying, the high-purity argon gas with a flow rate of 90 sccm is formed to form a protective atmosphere;

[0055] (4) Deposition: Fill the above-mentioned molten metal into the molten metal bag and pass high-purity argon gas with a pressure of 0.9MPa. The molten metal is atomized through a no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com