A waterproof and crack-resistant exterior wall thermal insulation structure

A technology for external wall thermal insulation and building waterproofing, which is applied in building construction, construction, covering/lining, etc., and can solve the problems of external wall thermal insulation structure engineering quality, adverse effects on service life, waterproof, poor crack resistance, cracks, etc. , to achieve good corrosion resistance, precise and stable shape, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation of the modified halloysite nanotubes is as follows: the amido-modified halloysite nanotubes are reacted with an organic modifier under the conditions of cuprous chloride and pentamethyldiethylenetriamine as a catalyst, and the organic The double bond at one end of the modifying agent molecule can cross-link and polymerize with the carbon atom adjacent to the amide group in the amide-modified halloysite nanotube to form a polymer coating on the surface of the halloysite nanotube.

[0045] When the existing cement waterproof and anti-cracking mortar is in a humid and low-temperature environment on the water surface, the hydration reaction of the mortar is incomplete, which limits the physical performance of the mortar in all aspects and greatly limits its application. The modified halloysite nanotubes prepared by the present invention can combine with Ca(OH) in the cement hydration product due to containing multiple active groups. 2 Generate gel substances...

Embodiment 1

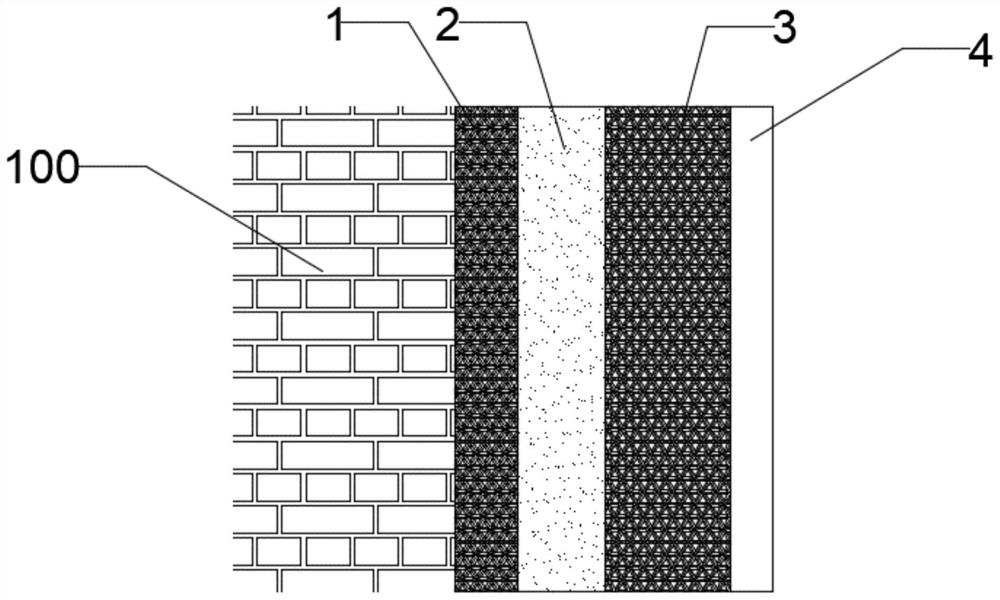

[0048] A waterproof and crack-resistant exterior wall insulation structure, such as figure 1 As shown, it includes the first waterproof and anti-crack layer 1, the insulation layer 2, and the second waterproof and anti-crack layer 3 arranged in sequence near the wall. Between the crack layer 1 and the second waterproof and crack-resistant layer 3;

[0049] Wherein, both the first waterproof and anti-crack layer 1 and the second waterproof and anti-crack layer 3 are prepared from waterproof and anti-crack mortar materials, and the waterproof and anti-crack mortar materials are composed of the following components in parts by weight:

[0050] 100 parts of Portland cement, 585 parts of medium sand, 102 parts of water, 53 parts of fly ash, 20 parts of modified halloysite nanotubes, 16 parts of polypropylene fiber, 7 parts of redispersible latex powder and 2 parts of water reducing agent.

[0051] The insulation layer 2 is prepared from the insulation mortar material, and the ins...

Embodiment 2

[0076] A waterproof and crack-resistant exterior wall insulation structure, such as figure 1 As shown, it includes the first waterproof and anti-crack layer 1, the insulation layer 2, and the second waterproof and anti-crack layer 3 arranged in sequence near the wall. Between the crack layer 1 and the second waterproof and crack-resistant layer 3;

[0077] Wherein, both the first waterproof and anti-crack layer 1 and the second waterproof and anti-crack layer 3 are prepared from waterproof and anti-crack mortar materials, and the waterproof and anti-crack mortar materials are composed of the following components in parts by weight:

[0078] 100 parts of Portland cement, 500 parts of medium sand, 90 parts of water, 32 parts of fly ash, 10 parts of modified halloysite nanotubes, 8 parts of polypropylene fiber, 3 parts of redispersible latex powder and 1 part of water reducing agent.

[0079] The insulation layer 2 is prepared from the insulation mortar material, and the insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com