Nano titanium dioxide photocatalytic antibacterial material as well as preparation method and application thereof

A nano-titanium dioxide, antibacterial material technology, applied in chemical instruments and methods, physical/chemical process catalysts, antibacterial drugs, etc., can solve problems such as unfavorable photocatalytic reactions, easy recombination, easy particle agglomeration, etc., to improve the photocatalytic efficiency. , avoid particle agglomeration, easier separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In this embodiment, a preparation method of nano-titanium dioxide photocatalytic antibacterial material specifically includes the following steps:

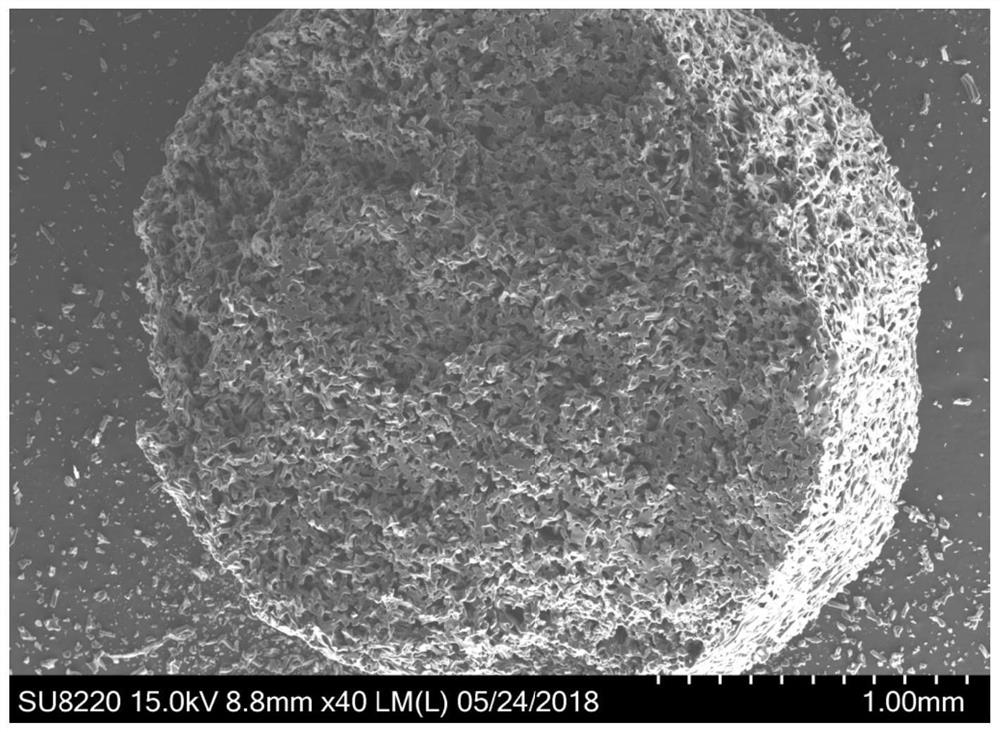

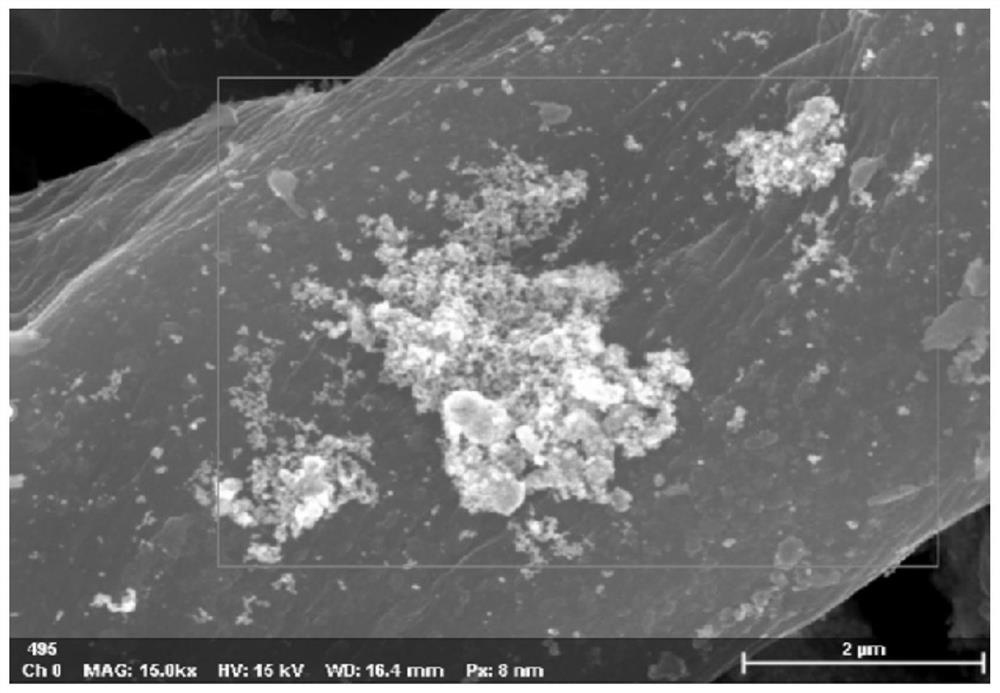

[0053] S1 Put the cigarette filter into a tube furnace, pass in an inert gas, slowly raise the temperature to 800°C at a rate of 15°C / min in an inert gas environment, keep the temperature for calcination for 30 minutes, and then cool naturally to obtain a carbonized cigarette filter;

[0054] S2 Add double-distilled water into the surfactant dodecylamine, stir until it is fully dissolved, adjust the pH value to 8, and then add titanium (IV) isopropoxide salt solution to make Ti in the titanium dioxide growth solution 4+ The concentration of ions is 0.25mol / L, and a titania growth solution is prepared;

[0055] S3 immersing the carbonized cigarette filter in the titanium dioxide growth solution and stirring for 30 min;

[0056] S4 Place the carbonized cigarette filter soaked in the titanium dioxide growth solution in a hydr...

Embodiment 2

[0060] In this embodiment, a preparation method of nano-titanium dioxide photocatalytic antibacterial material specifically includes the following steps:

[0061] S1 Put the cigarette filter into a tube furnace, pass in an inert gas, slowly raise the temperature to 700°C at a rate of 10°C / min in an inert gas environment, keep the temperature for calcination for 40 minutes, and then cool naturally to obtain a carbonized cigarette filter;

[0062] S2 Add double-distilled water into the surfactant dodecylamine, stir until it is fully dissolved, adjust the pH value to 9, and then add titanium (IV) isopropoxide salt solution to make Ti in the titanium dioxide growth solution 4+ The concentration of ions is 0.25mol / L, and a titania growth solution is prepared;

[0063] S3 immersing the carbonized cigarette filter in the titanium dioxide growth solution and stirring for 25 minutes;

[0064] S4 Place the carbonized cigarette filter soaked in the titanium dioxide growth solution in a ...

Embodiment 3

[0068] In this embodiment, a preparation method of nano-titanium dioxide photocatalytic antibacterial material specifically includes the following steps:

[0069] S1 Put the cigarette filter into a tube furnace, pass in an inert gas, slowly raise the temperature to 750°C at a rate of 20°C / min in an inert gas environment, keep the temperature for calcination for 20 minutes, and then cool naturally to obtain a carbonized cigarette filter;

[0070] S2 Add double-distilled water into the surfactant dodecylamine, stir until it is fully dissolved, adjust the pH value to 10, and then add titanium (IV) isopropoxide salt solution to make Ti in the titanium dioxide growth solution 4+ The concentration of ions is 0.25mol / L, and a titania growth solution is prepared;

[0071] S3 immersing the carbonized cigarette filter in the titanium dioxide growth solution and stirring for 40 min;

[0072] S4 Place the carbonized cigarette filter soaked in the titanium dioxide growth solution in a hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com