Treatment method for cleaning and recycling polytetrafluoroethylene reaction kettle

A technology of polytetrafluoroethylene and a treatment method, which is applied in the directions of cleaning methods, cleaning methods and utensils using liquids, cleaning hollow objects, etc., can solve the problems of no practical significance, acidic environment of the reaction kettle, and the inner wall is dyed yellow, etc. To achieve the effect of being beneficial to the removal of dirt, improving the ability of dissolution and penetration, and improving the penetration of solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

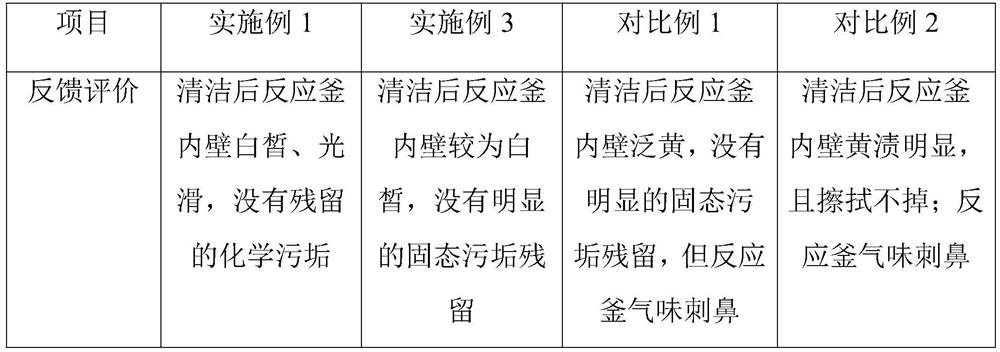

Examples

Embodiment 1

[0020] A treatment method for cleaning and reusing a polytetrafluoroethylene reactor, comprising the steps of:

[0021] (1) At first the polluted polytetrafluoroethylene reactor is collected, soaked for 2h with 10% ethyl acetate solution, then repeatedly scrub the inner and outer walls of the reactor for 3 times, then rinse with tap water; then the reactor is transferred to In an ultrasonic machine equipped with 1L, 9% citric acid / polyethylene glycol-400 mixed solution, perform ultrasonic cleaning at 60°C for 2 hours; then replace the citric acid / polyethylene glycol-400 mixed solution in the ultrasonic machine with Ionized water, continue ultrasonic cleaning for 3 times, each time for 0.5h;

[0022] (2) Take out the polytetrafluoroethylene reactor after cleaning in step (1) and pour 60mL, 6% hydrofluoric acid solution into each reactor, add 0.25g sodium hexametaphosphate, ultrasonically disperse for 20min, Then seal it, install the outer lining of the reaction kettle, and hea...

Embodiment 2

[0025] A treatment method for cleaning and reusing a polytetrafluoroethylene reactor, comprising the steps of:

[0026] (1) At first the polluted polytetrafluoroethylene reactor is collected, soaked for 2h with 10% ethyl acetate solution, then repeatedly scrub the inner and outer walls of the reactor for 3 times, then rinse with tap water; then the reactor is transferred to In an ultrasonic machine equipped with 1L, 8% sulfamic acid / ethylenediaminetetramethylphosphinic acid solution, citric acid / polyethylene glycol-400 mixed solution, ultrasonically clean at 60°C for 2 hours; then put the Replace the sulfamic acid / ethylenediaminetetramethylphosphinic acid solution with citric acid / polyethylene glycol-400 mixed solution with deionized water, and continue ultrasonic cleaning for 3 times, each time for 0.5h;

[0027] (2) Take out the polytetrafluoroethylene reaction kettle after cleaning in step (1) and pour 60mL, 6% hydrofluoric acid solution into each reaction kettle, add 0.3g ...

Embodiment 3

[0030] A treatment method for cleaning and reusing a polytetrafluoroethylene reactor, comprising the steps of:

[0031] (1) At first the polluted polytetrafluoroethylene reactor is collected, soaked for 2h with 10% ethyl acetate solution, then repeatedly scrub the inner and outer walls of the reactor for 3 times, then rinse with tap water; then the reactor is transferred to In an ultrasonic machine equipped with 1L, 5% citric acid / polyethylene glycol-400 mixed solution, perform ultrasonic cleaning at 60°C for 2 hours; then replace the citric acid / polyethylene glycol-400 mixed solution in the ultrasonic machine with Ionized water, continue ultrasonic cleaning for 3 times, each time for 0.5h;

[0032] (2) Take out the polytetrafluoroethylene reactor after cleaning in step (1) and pour 60mL, 5% hydrofluoric acid solution into each reactor, add 0.1g sodium hexametaphosphate, ultrasonically disperse for 20min, Then seal it, install the outer lining of the reaction kettle, and heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com