Process for treating surfactant wastewater by using foam separation tower

A surfactant and foam separation technology, applied in multi-stage water treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of incomplete separation and air flotation separation equipment without multi-stage separation Function, low separation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

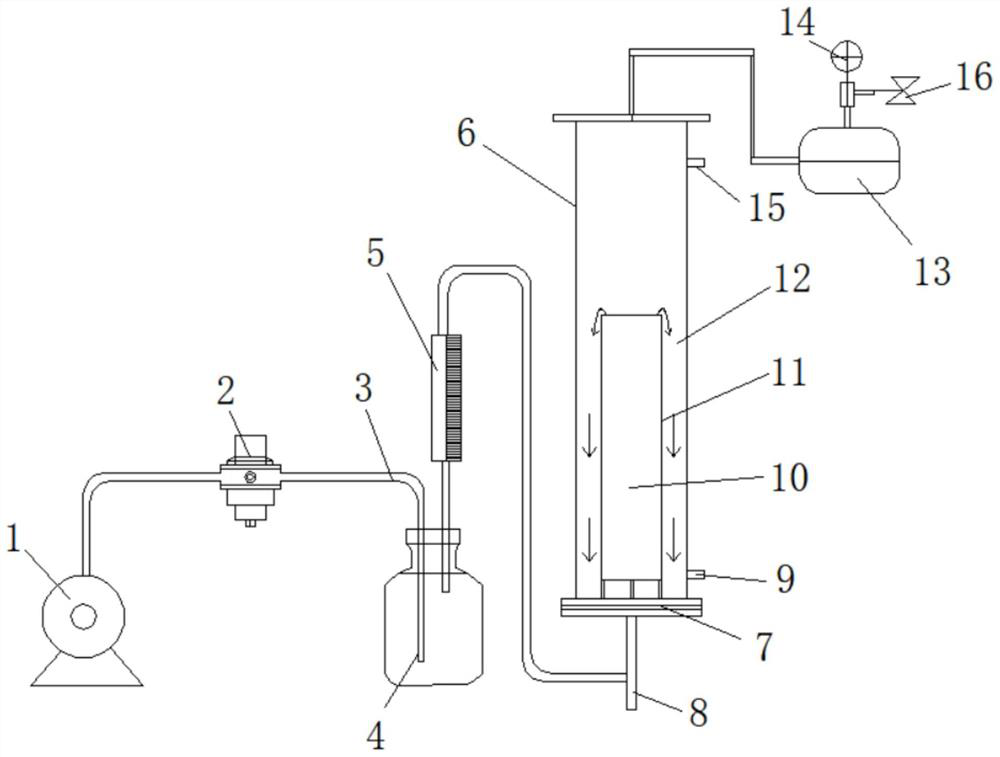

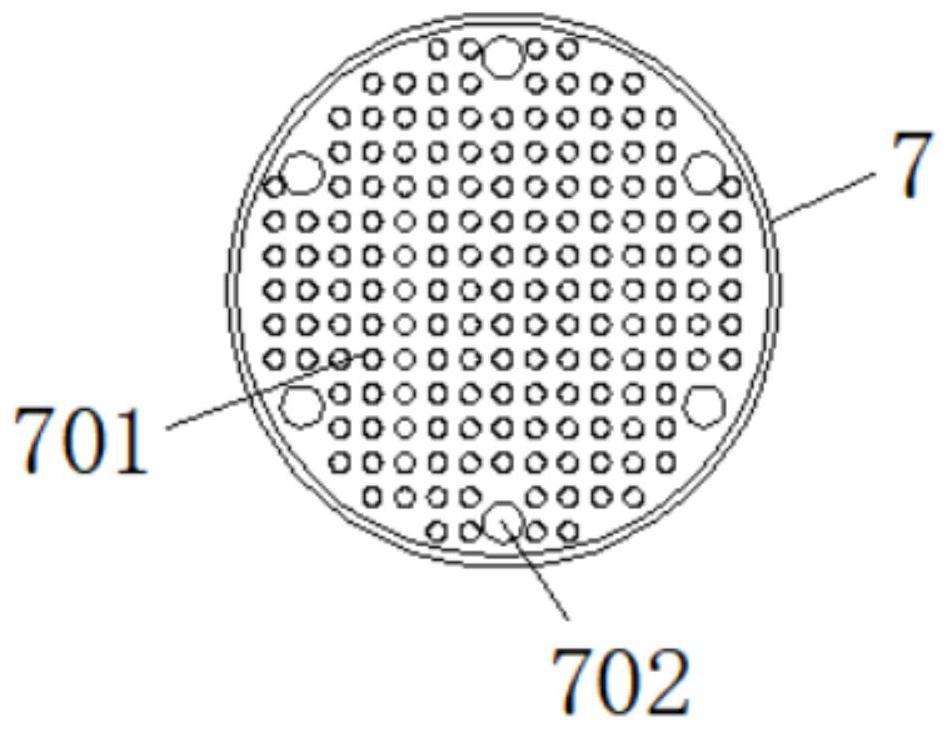

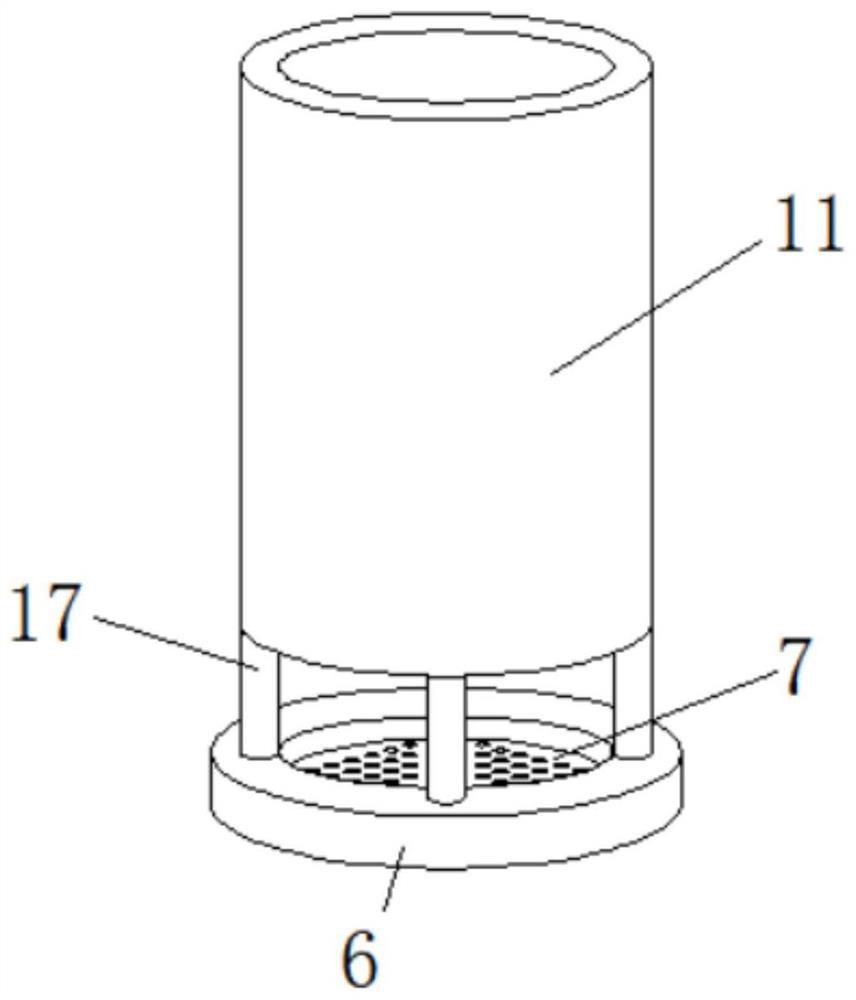

[0035] see figure 1 , 2, 4 and 5, a kind of technology that adopts foam separation tower to treat surfactant wastewater, experiment adopts simulated surfactant wastewater cetyltrimethylammonium bromide (CTAB) aqueous solution as system, concentration is 100mg / L, experiment For intermittent operation, the treatment capacity of each batch of wastewater is 350mL; the pH value of the solution is adjusted by adding HCl or NaOH to the simulated industrial wastewater; the surfactant wastewater solution is injected from the top of the tower body through the sampling port 15, and the liquid volume is high 350mm, gas velocity = 300mL / min, the temperature of the experiment is maintained at (22 ± 1) ° C, the liquid sample is collected from the sampling port 15 on the side; the internal circulation flow foam separation tower 6 operates the system, including the air compressor 1 and the pressure stabilizing valve 2. Conduit 3, gas buffer bottle 4, rotameter 5, foam separation tower 6, gas ...

specific Embodiment 2

[0041] see Figure 1-6 , a process for treating surfactant wastewater using a foam separation tower. The experiment uses a simulated surfactant wastewater cetyltrimethylammonium bromide (CTAB) aqueous solution as the system, and the CTAB concentration is 3.0g L -1 , the experiment is intermittent operation, and the treatment capacity of each batch of wastewater is 350mL; the pH value of the solution is adjusted by adding HCl or NaOH in the simulated industrial wastewater; the surfactant wastewater solution is injected from the top of the tower body through the sampling port 15, and the liquid is filled The measurement height is 350mm, the gas velocity=300mL / min, the temperature of the experiment is maintained at (22 ± 1) ℃, and the liquid sample is collected from the sampling port 15 on the side; the operating system of the internal circulation foam separation tower 6 includes an air compressor 1, a stable Pressure valve 2, conduit 3, gas buffer bottle 4, rotameter 5, foam sep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com