Method for preparing organic fertilizer from antibiotic mushroom dregs and product thereof

A technology of antibiotic bacterial residue and organic fertilizer, which is applied in the preparation of organic fertilizer, organic fertilizer, biological organic part treatment and other directions, can solve problems such as secondary pollution, and achieve the effect of simple method and solving difficult treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

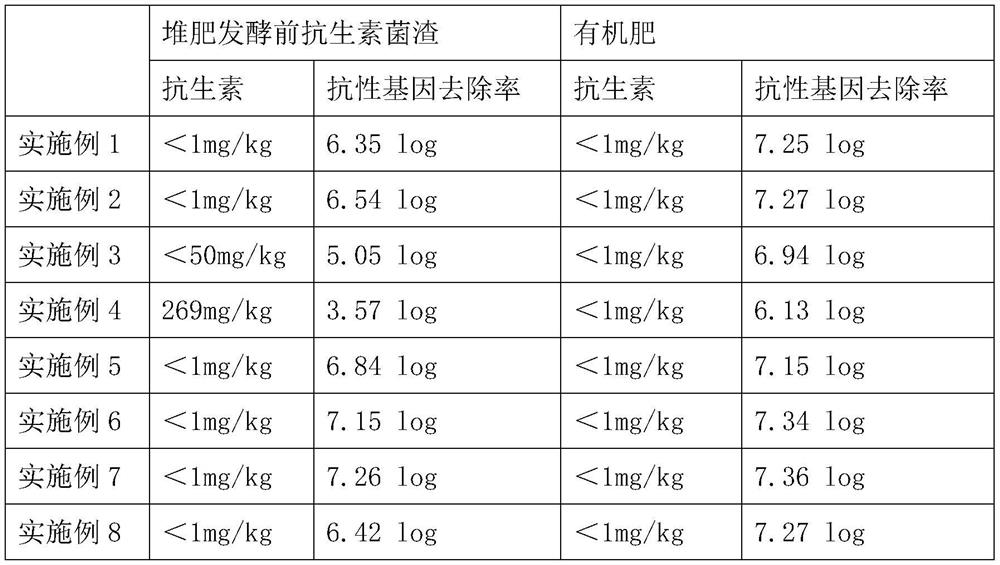

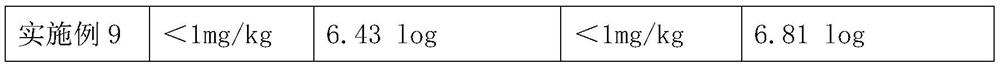

Examples

Embodiment 1

[0024] The residual amount of gentamycin is 2600mg / kg, and the antibiotic slag is adjusted to 85% water content and placed in microwave ultrasonic reaction, wherein the microwave treatment time is 15min under the ultrasonic condition at the sound frequency of 150KHz, and the microwave power is 700W, and the organic solid waste After mixing according to the mass ratio of 3:1, adjust the water content to 65%, and carry out aerobic composting and fermentation for 30 days after the pH value is 7.5.

Embodiment 2

[0026] After adjusting the water content of antibiotic bacteria slag to 80%, place it in microwave ultrasonic reaction, in which the sound frequency is 200KHz, the microwave power is 1000W, and the microwave treatment time is 10min under ultrasonic conditions. After mixing with organic solid waste according to the mass ratio of 3:1, the content The water content is 65%, and the pH value is 7.0. After 35 days of aerobic composting and fermentation, the composting is turned every 5 days. The composting fermentation product is dried, crushed and granulated to obtain organic fertilizer.

Embodiment 3

[0028] Same as Example 1, the difference is that the ultrasonic condition is omitted during the microwave treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com