Metallization electroplating method for plastic shell and wear-resistant plastic

A plastic shell and metallization technology, applied in the field of material coating metal, can solve the problems of poor corrosion resistance and wear resistance, chromium ion pollution, low bonding performance, etc., to improve strength, reduce polarization phenomenon, and the method is simple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

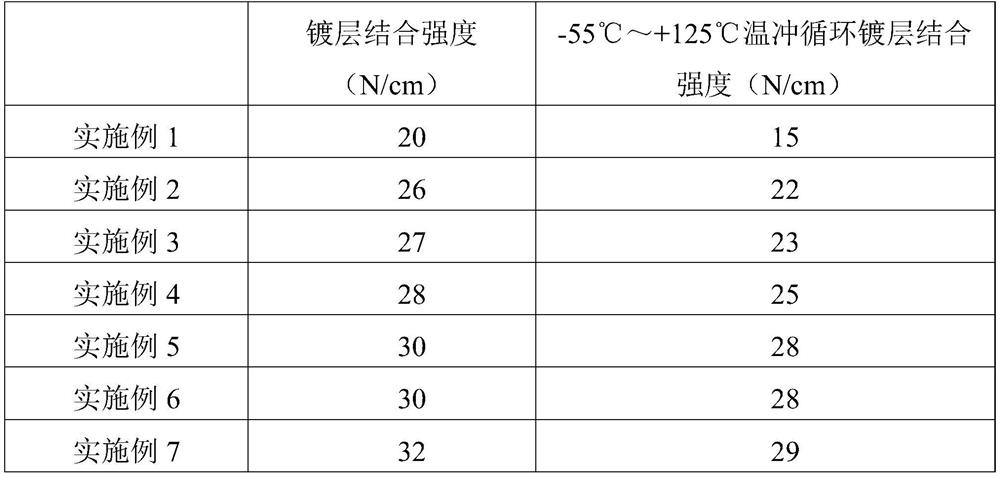

Examples

Embodiment 1

[0061] The metallization electroplating method for plastic shells consists of the following steps:

[0062] S1. Pretreatment: first clean the plastic with a mixture of acetone and absolute ethanol for 8 minutes, the mass ratio of the acetone and absolute ethanol is 1:1; then wash it with an aqueous solution of sodium carbonate at 50°C and pH=7.5 for 5 minutes; then Wash with pH=6 acetic acid aqueous solution for 2 minutes, and finally wash with 40°C deionized water for 4 minutes to obtain pretreated plastic; the plastic is polycarbonate plastic;

[0063] S2. Coarsening: Put the pretreated plastic into a microetching solution at 55° C. for 20 minutes at an ultrasonic power of 160 W and an ultrasonic frequency of 25 kHz to obtain a microetching plastic; the microetching solution is composed of 25 wt % phosphoric acid, 60 wt % sulfuric acid, and 5 wt % MnO 2 , 0.03wt% cetyltrimethylammonium bromide, 0.5wt% sodium tripolyphosphate, and the balance is deionized water;

[0064] S3,...

Embodiment 2

[0072] The metallization electroplating method for plastic shells consists of the following steps:

[0073] S1. Pretreatment: first clean the plastic with a mixture of acetone and absolute ethanol for 8 minutes, the mass ratio of the acetone and absolute ethanol is 1:1; then wash it with an aqueous solution of sodium carbonate at 50°C and pH=7.5 for 5 minutes; then Wash with pH=6 acetic acid aqueous solution for 2 minutes, and finally wash with 40°C deionized water for 4 minutes to obtain pretreated plastic; the plastic is polycarbonate plastic;

[0074] S2. Coarsening: Soak the pretreated plastic in a swelling solution at 40°C for 10 minutes, then put it in a microetching solution at 55°C, and treat it for 20 minutes at an ultrasonic power of 160W and an ultrasonic frequency of 25kHz to obtain a microetched plastic; The swelling liquid is mixed with 20wt% 5-carboxybenzotriazole, 30wt% N-methylpyrrolidone, 15wt% potassium hydroxide, 10wt% N,N-dimethylformamide, and the balance...

Embodiment 3

[0083] The metallization electroplating method for plastic shells consists of the following steps:

[0084] S1. Pretreatment: first clean the plastic with a mixture of acetone and absolute ethanol for 8 minutes, the mass ratio of the acetone and absolute ethanol is 1:1; then wash it with an aqueous solution of sodium carbonate at 50°C and pH=7.5 for 5 minutes; then Wash with pH=6 acetic acid aqueous solution for 2 minutes, and finally wash with 40°C deionized water for 4 minutes to obtain pretreated plastic; the plastic is polycarbonate plastic;

[0085] S2. Coarsening: Soak the pretreated plastic in a swelling solution at 40°C for 10 minutes, then put it in a microetching solution at 55°C, and treat it for 20 minutes at an ultrasonic power of 160W and an ultrasonic frequency of 25kHz to obtain a microetched plastic; The swelling liquid is mixed with 20wt% 5-carboxybenzotriazole, 30wt% N-methylpyrrolidone, 15wt% potassium hydroxide, 10wt% N,N-dimethylformamide, and the balance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com