Heat-resistant rare earth aluminum alloy conductor for power cable and processing technology of heat-resistant rare earth aluminum alloy conductor

A technology of aluminum alloy conductors and power cables, which is applied in the direction of power cables, metal/alloy conductors, cable/conductor manufacturing, etc., can solve the problems of affecting the service life of cables, cable damage, and lack of heat resistance, so as to improve the performance of use , save energy, overcome the effect of heat intolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

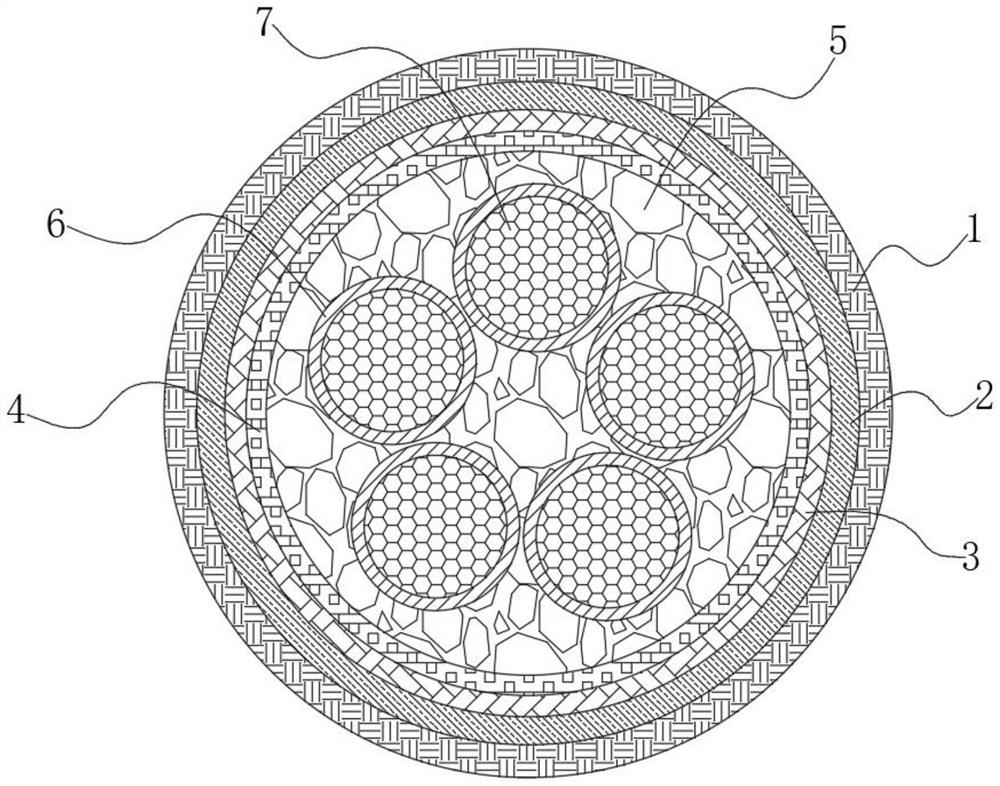

[0025] see figure 1 , the present invention provides a technical solution: a heat-resistant rare earth aluminum alloy conductor for power cables, comprising an outer sheath 1, the inner wall of the outer sheath 1 is fixedly connected with an armored layer 2, and the inner wall of the armored layer 2 is fixedly connected with a Inner lining layer 3, the inner wall of inner lining layer 3 is fixedly connected with packing tape 4, the inner wall of packing tape 4 is fixedly connected with filling layer 5, the inner wall of filling layer 5 is fixedly connected with insulating layer 6, and the inner wall of insulating layer 6 is fixedly connected with Aluminum alloy conductor 7.

[0026] A process for processing a heat-resistant rare earth aluminum alloy conductor for power cables, the process comprising the following steps:

[0027] 1): Material selection: silicon: 0.08; iron: 0.6; copper: 0.03; zirconium: 0.5; yttrium: 0.5; aluminum ingots with an aluminum content of more than 9...

Embodiment 2

[0037] The invention provides a technical solution: a heat-resistant rare earth aluminum alloy conductor for power cables, comprising an outer sheath 1, the inner wall of the outer sheath 1 is fixedly connected with an armor layer 2, and the inner wall of the armor layer 2 is fixedly connected with an inner Lining layer 3, the inner wall of inner lining layer 3 is fixedly connected with wrapping tape 4, the inner wall of wrapping tape 4 is fixedly connected with filling layer 5, the inner wall of filling layer 5 is fixedly connected with insulating layer 6, the inner wall of insulating layer 6 is fixedly connected with aluminum alloy conductor7.

[0038] A process for processing a heat-resistant rare earth aluminum alloy conductor for power cables, the process comprising the following steps:

[0039] 1): Material selection: silicon: 0.07; iron: 0.5; copper: 0.03; zirconium: 0.5; yttrium: 0.5; aluminum ingots with an aluminum content of more than 99.5%;

[0040] 2): Mixing of ...

Embodiment 3

[0049] The invention provides a technical solution: a heat-resistant rare earth aluminum alloy conductor for power cables, comprising an outer sheath 1, the inner wall of the outer sheath 1 is fixedly connected with an armor layer 2, and the inner wall of the armor layer 2 is fixedly connected with an inner Lining layer 3, the inner wall of inner lining layer 3 is fixedly connected with wrapping tape 4, the inner wall of wrapping tape 4 is fixedly connected with filling layer 5, the inner wall of filling layer 5 is fixedly connected with insulating layer 6, the inner wall of insulating layer 6 is fixedly connected with aluminum alloy conductor7.

[0050] A process for processing a heat-resistant rare earth aluminum alloy conductor for power cables, the process comprising the following steps:

[0051] 1): Material selection: silicon: 0.06; iron: 0.5; copper: 0.02; zirconium: 0.4; yttrium: 0.4; aluminum ingots with an aluminum content of more than 99.5%;

[0052]2): Mixing of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com