Semiconductor HEMT device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as device cracking, lattice mismatch and thermal mismatch, and achieve not easy to fall off and reduce stress Concentrated, easy-off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

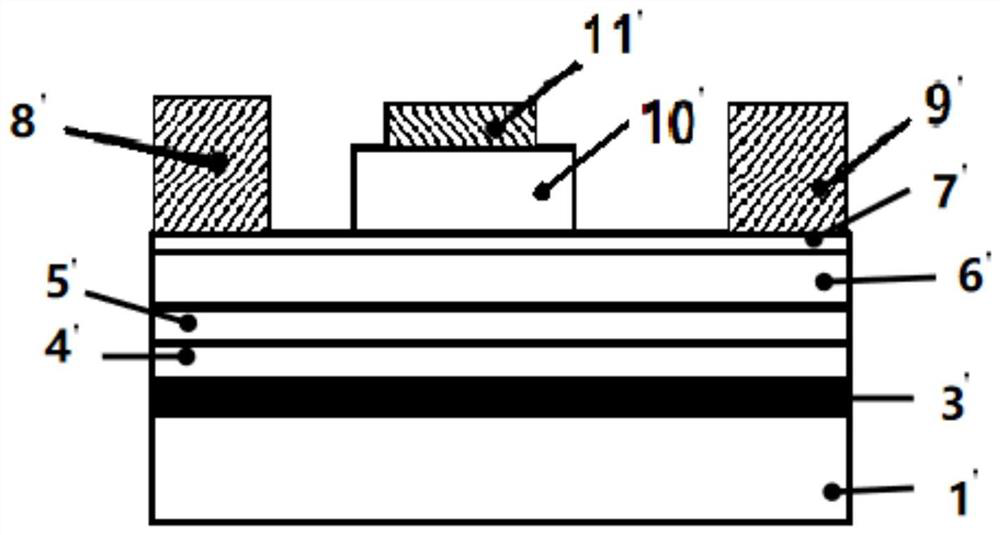

[0038] refer to Figure 9 , the present embodiment provides a semiconductor HEMT device, comprising:

[0039] Substrate Substrate 1.

[0040] The heat conduction layer, the heat conduction layer is located on the surface of one side of the base substrate 1 .

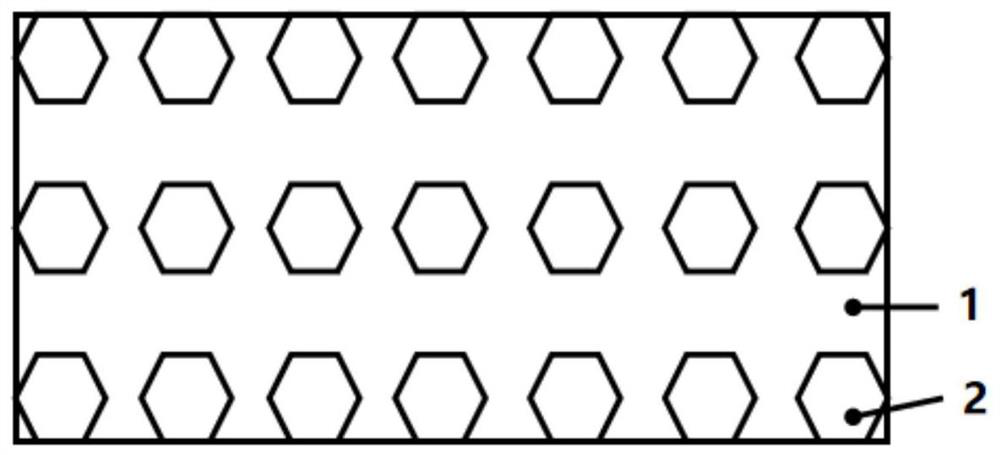

[0041] The heat conduction layer includes: a plurality of support structures 2 and heat conduction structures 3 arranged at intervals, the support structure 2 is located on one side surface of the base substrate 1; the heat conduction structure 3 is located on the surface of the base substrate 1 on the same side as the support structure 2, and the heat conduction structure 3 filling the gaps between the plurality of support structures 2.

[0042] The insulating layer 4 covers the surface of the heat conducting structure 3 facing away from the base substrate 1 , and the insulating layer 4 also covers the surfaces of the plurality of support structures 2 facing away from the base substrate 1 .

[0043] Wherein, the heat...

Embodiment 2

[0059] refer to Figure 2-Figure 9 , the present embodiment provides a method for manufacturing a semiconductor HEMT device, comprising the following steps:

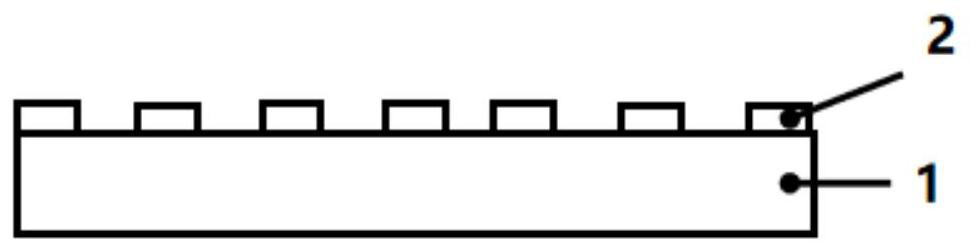

[0060] providing a base substrate 1;

[0061] refer to Figure 2-Figure 5 , forming a heat conduction layer, the step of forming a heat conduction layer includes: forming a plurality of support structures 2 at intervals on one side surface of the base substrate 1; and then forming a heat conduction structure 3 on the side surface of the support structure 2 formed on the base substrate 1 , the heat conducting structure 3 fills the gaps between the plurality of supporting structures 2 .

[0062] An insulating layer 4 is formed, and the insulating layer 4 covers the surface of the thermally conductive structure 3 facing away from the base substrate 1 , and the insulating layer 4 also covers the surfaces of the plurality of support structures 2 facing away from the base substrate 1 .

[0063] The heat conducting structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com