Photovoltaic module with light reflecting device

A photovoltaic module and reflective device technology, applied in the field of solar energy, can solve the problems of solar cell heating reducing photoelectric conversion efficiency, inability to convert, affecting safe operation, etc., to achieve the effect of reducing photoelectric conversion efficiency and avoiding heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0029] Beamsplitters are used to reflect and transmit light. According to different spectral characteristics, beamsplitters can be divided into neutral beamsplitters and dichroic beamsplitters. A neutral beamsplitter can split a beam of light into two beams with the same spectral composition; a dichroic beamsplitter can reflect one part of the spectrum and transmit the other part.

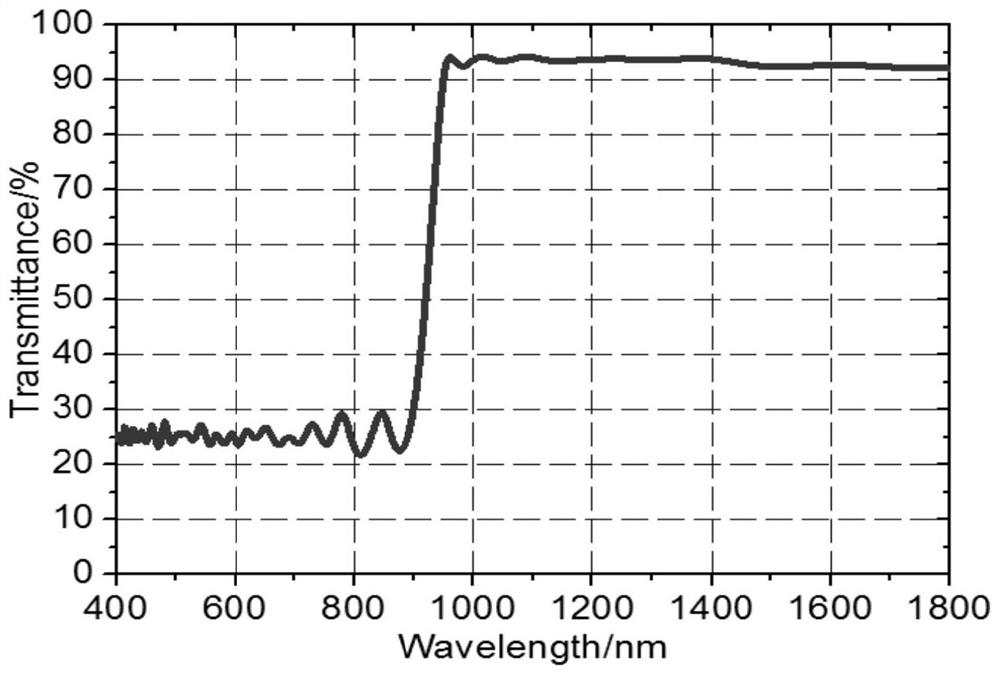

[0030] The invention discloses a photovoltaic component with a reflective device, which uses a reflective film with a cut-off wavelength of 900nm. The reflective film used in the present invention splits the solar spectrum at 900nm to divide the solar spectrum into two parts, long wave and short wave. The 900nm cut-off wavelength can be selected from GaAs single-junction solar cells, single-junction dye-sensitized solar cells, single-junction silicon thin-film solar cells, crystalline silicon solar cells, cadmium telluride solar cells and copper indium gallium selenide solar cells.

Embodiment 1

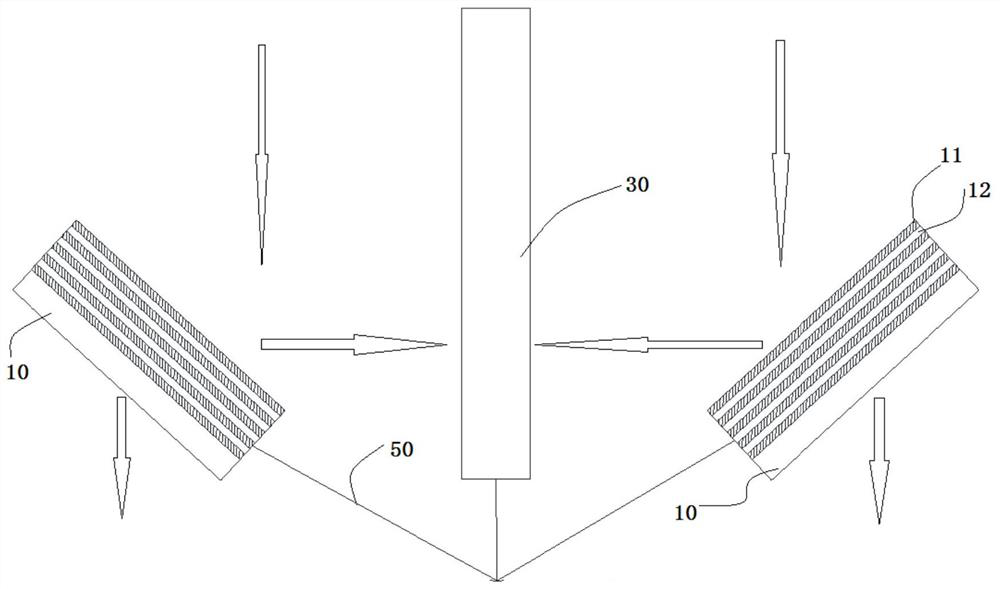

[0032] see figure 1 As shown, the present invention provides a photovoltaic module with a reflective device, including two reflective films, a photovoltaic module 30 and a fixing bracket 50 .

[0033] The working angle of the reflective film is 45°; the photovoltaic module 30 is double-sided photovoltaic;

[0034] The two reflective films are arranged on both sides of the photovoltaic module 30 , and the angle between them and the photovoltaic module 30 is 45°. The photovoltaic module 30 is disposed on the reflective side of the reflective film.

[0035] The two reflective films and the photovoltaic module 30 are fixed on the fixing bracket 50 to fix their positions and angles.

[0036] Sunlight is vertically incident on the reflective film set at 45°, and the short-wavelength light energy with a wavelength below 900nm is reflected to the surfaces of both sides of the photovoltaic module 30 for photovoltaic power generation. Control the temperature rise of photovoltaic modu...

Embodiment 2

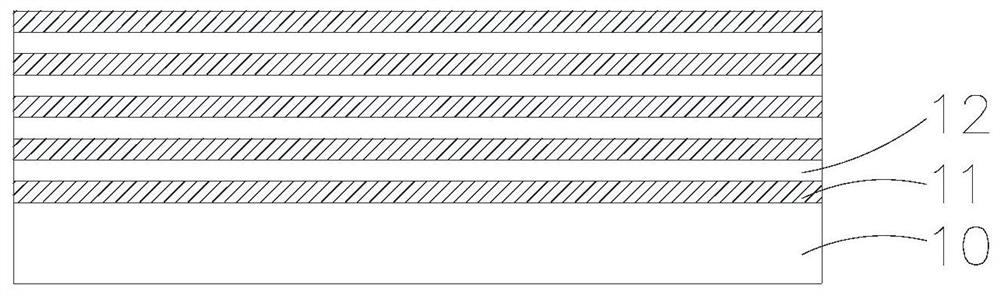

[0038] see figure 2 As shown, the reflective film in the present invention includes a substrate 10 and a coating film disposed on the substrate; the coating film includes a first material coating layer 11 and a second material coating layer 12 sequentially overlapped and disposed on the substrate. Both the bottom layer and the topmost layer of the coating are coating layers of the first material. The first material coating layer 11 and the second material coating layer 12 are respectively a high refractive index material coating layer and a low refractive index material coating layer.

[0039] The working band of the reflective film is 400-1800nm, and the substrate 10 is made of hard materials: aluminum sheets, steel sheets, copper sheets, glass sheets, quartz sheets, high borosilicate materials, etc., or flexible plastic substrates, such as EVA film, PI film, etc. .

[0040] The working angle of the reflective film is 45°, and the transmittance in the 400-900nm band is req...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap