Reflecting film for photovoltaic module and preparation method of reflecting film

A photovoltaic module and reflective film technology, which is applied in the field of solar energy, can solve problems such as inability to convert, solar cells reduce photoelectric conversion efficiency, and affect the safe operation of photovoltaic modules, so as to achieve the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

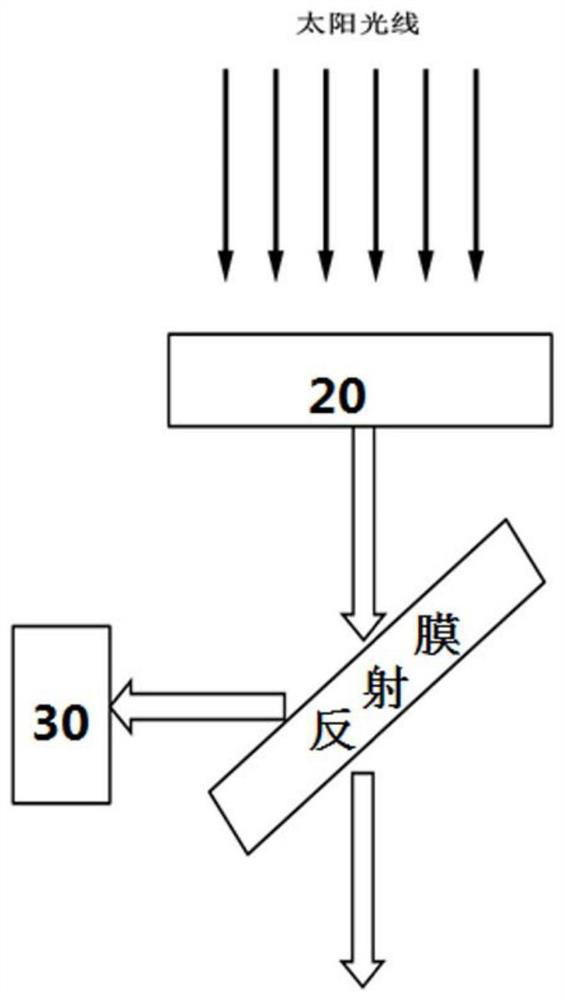

[0034] Beamsplitters are used to reflect and transmit light. According to different spectral characteristics, beamsplitters can be divided into neutral beamsplitters and dichroic beamsplitters. A neutral beamsplitter can split a beam of light into two beams with the same spectral composition; a dichroic beamsplitter can reflect one part of the spectrum and transmit the other part.

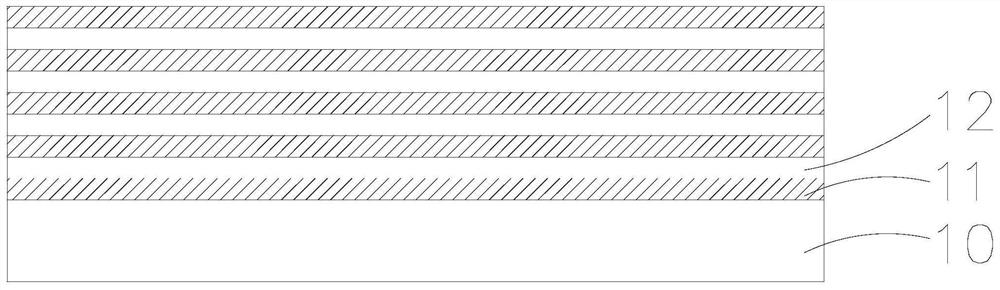

[0035] The invention provides a reflective film for a photovoltaic module. Different cut-off wavelengths can be selected according to the photovoltaic module used. Common wavelengths are 900nm, 1100nm, 1500nm, 1800nm and the like.

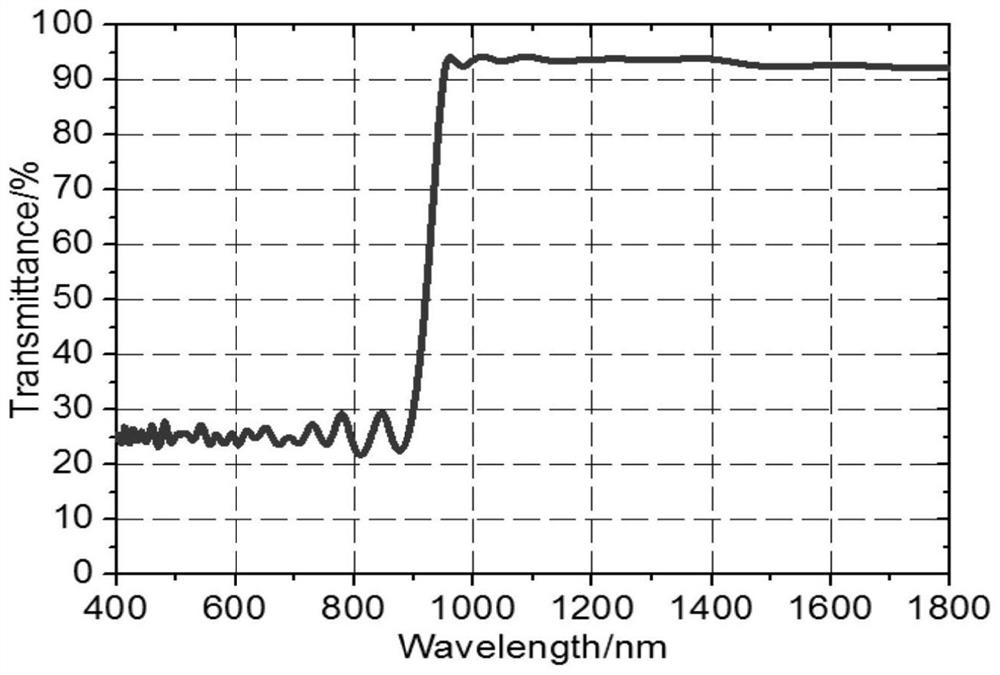

[0036] In the following, the cutoff wavelength is 900nm as an example for illustration. The reflective film of the present invention performs light splitting at 900nm to divide the solar spectrum into two parts, long wave and short wave. The long-wavelength light can use its thermal energy. The 900nm cut-off wavelength can be selected from GaAs single-junction solar...

Embodiment 2

[0044] The present invention also provides a method for preparing a reflective film for a photovoltaic module. The preparation of the coating film is completed on a 900Plus box-type vacuum coating machine produced by the German Leybold company.

[0045] The vacuum system of the box-type vacuum coating machine adopts the configuration of mechanical pump + oil diffusion pump, and the ultimate vacuum can reach 2×10 -4 Pa. Evaporation sources are: two e-type electron guns and two sets of anti-evaporation electrodes. The high voltage of the two electron guns is 10KV, and the voltage of the resistance evaporation electrode is 6V, and the power of the evaporation source can be adjusted according to the needs. The fixture is a magnetic fluid sealed high-speed rotary fixture with adjustable speed up to 800rad / min.

[0046] Film thickness monitoring adopts 4-probe IC / 5 quartz crystal oscillator + transparent and reflective optical direct monitoring, and is equipped with OMS3000 automa...

Embodiment 3

[0054] The present invention also provides a method for preparing a reflective film for a photovoltaic module, comprising:

[0055] The first step is to use CNC numerical control machine tools with high processing precision, high rigidity and high degree of automation to cut glass blanks into semi-finished products;

[0056] In the second step, the glass engraving and milling machine is used to shape and edge the semi-finished lens;

[0057] The third step is to polish the carved lenses. The mechanism of polishing is the same as that of grinding, except that the tool material used is different from the polishing fluid. Usually, it is necessary to achieve a high-precision polishing surface. The most commonly used material is high-grade polishing asphalt. Using asphalt to polish is to use the fine surface of asphalt to drive the polishing liquid to grind the surface of the lens to generate heat, so that the glass melts and flows, melts away the rough apex and fills the bottom o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap