Temperature difference mixing preparation process for multi-strain step-by-step fermentation of carbonated beverage

A step-by-step fermentation and preparation technology, which is applied in applications, dairy products, milk preparations, etc., can solve the problems of strain competition and inhibition, achieve full flavor, avoid competition inhibition, and drink safely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

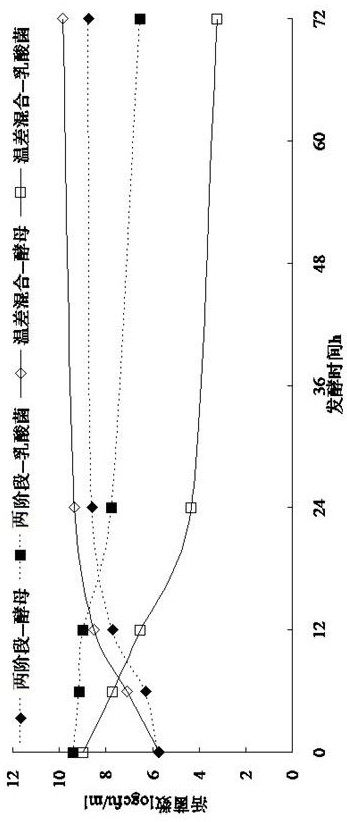

Image

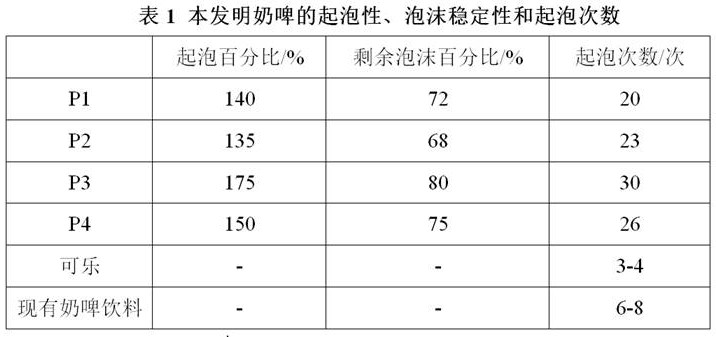

Examples

Embodiment 1

[0026] The temperature difference mixing preparation process of milk beer provided in this embodiment specifically includes the following steps:

[0027] Preparation of yogurt: Take 100 parts of standardized milk and put it in a fermentation tank, add 8 parts of sugar (glucose:sucrose=4:6, w / w), preheat to 40°C, homogenize at 20Mpa and pasteurize After sterilization, 0.1 part of Lactobacillus bulgaricus was inoculated and fermented at 42°C for 9 hours. At this time, the pH value of the system was 5.0, and the fermentation was stopped to obtain yogurt with high viscosity;

[0028] Temperature difference mixing: add sodium bicarbonate and citric acid (w / w=1 / 2.5), which account for 0.1% of the total weight of milk and sugar, into hot water at 75°C, and then add the above yogurt and 400 parts of hot water to the fermentation tank at the same time. Yogurt was added from the top, hot water was added from the bottom, then rapidly cooled, cooled to 40°C, homogenized at 20Mpa, inoculat...

Embodiment 2

[0030] The temperature difference mixing preparation process of milk beer provided in this embodiment specifically includes the following steps:

[0031] Preparation of yogurt: Take 100 parts of standardized milk and put it in a fermentation tank, add 8 parts of sugar (glucose:sucrose=4:6, w / w), preheat to 80℃, homogenize at 18Mpa and pasteurize After sterilization, 0.1 part of Lactobacillus bulgaricus was inoculated and fermented at 42°C for 9 hours. At this time, the pH value of the system was 5.0, and the fermentation was stopped to obtain yogurt with high viscosity;

[0032] Temperature difference mixing: add sodium bicarbonate and malic acid (w / w=1 / 2.5), which account for 0.2% of the total weight of milk and sugar, into hot water at 80°C, and then add the above yogurt and 400 parts of hot water to the fermentation tank at the same time. Yogurt was added from the top, hot water was added from the bottom, then rapidly cooled, cooled to 40°C, homogenized at 20Mpa, and then i...

Embodiment 3

[0034] The temperature difference mixing preparation process of milk beer provided in this embodiment specifically includes the following steps:

[0035] Preparation of yogurt: Take 100 parts of standardized milk and place it in a fermentation tank, add 8 parts of sugar (glucose:sucrose=4:6, w / w), preheat to 60℃, homogenize at 18Mpa and pasteurize After sterilization, inoculate 0.1 part of Lactobacillus bulgaricus, ferment at 42°C for 12 hours, measure the pH value of the system to 3.8, and obtain solid yogurt, add 0.5 part of the emulsion stabilizer pectin to the solid yogurt, and turn on the stirring device for stirring. broken spare;

[0036]Temperature difference mixing: add sodium bicarbonate and malic acid (w / w=1 / 2.9), which account for 0.25% of the total weight of milk and sugar, into hot water at 85°C, and then add the above yogurt and 450 parts of hot water to the fermentation tank at the same time. Yogurt was added from the top, hot water was added from the bottom, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com