Fructo-oligosaccharide Chinese wolfberry vinegar and preparation method thereof

A technology of fructooligosaccharides and wolfberry, which is applied in the preparation of vinegar, biochemical equipment and methods, and methods based on microorganisms, etc., can solve the problems of insufficient functional ingredient content, low functional ingredient content, weak health care effect, etc. Health benefits, increased polyphenol content, increased taste and mouthfeel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

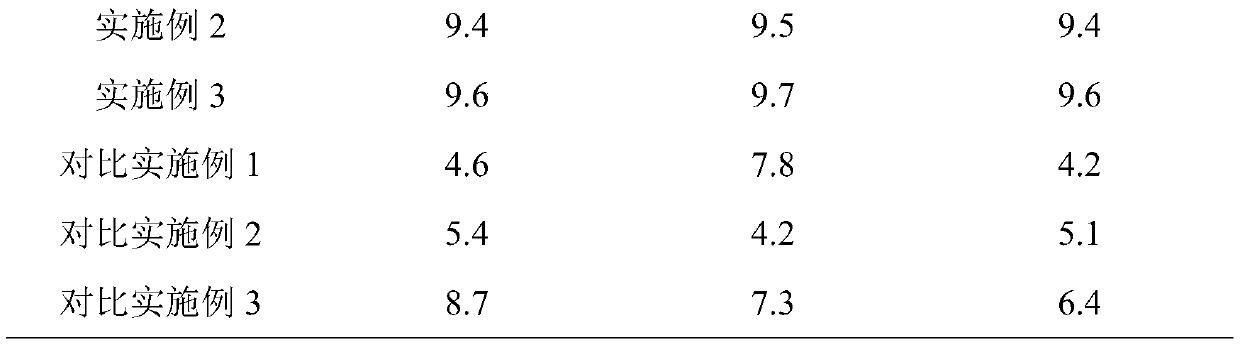

Embodiment 1

[0028] (1) Weigh 150kg of sun-dried chicory roots, wash them, cut them into sections, add 150kg of water to soak for 5 hours, and after draining, place the wet material under a pressure of 1.5Mpa and cook for 20min to obtain chicory root pulp, add 22.5kg of Water to obtain the chicory root slurry, according to the percentage per thousand of the weight of the mixed slurry, then add 0.52‰ of fructosyltransferase with an enzyme activity of 500,000 U / g, 0.84‰ of glucose oxidase with an enzyme activity of 100,000 U / g and 30 0.25‰ of glucose isomerase per 10,000 U / g, and hydrolyzed for 6-8 hours at 45°C to obtain a slurry containing fructooligosaccharides.

[0029] (2) Weigh 150kg of fresh medlar, soak in 150kg of water at 20°C for 1 hour, use a colloid mill to refine the beating, and heat it with a plate heat exchanger to inactivate the enzyme and prevent browning. The enzyme inactivation temperature is 100°C for 5 minutes to obtain wolfberry juice.

[0030] (3) The wolfberry juic...

Embodiment 2

[0035] (1) Weigh 150kg of sun-dried chicory roots, wash them, cut into sections, add 150kg of water to soak for 5 hours, and after draining, place the wet material under a pressure of 1.6Mpa and cook for 25min to obtain chicory root pulp, add 22.5kg of Water to obtain the chicory root slurry, according to the percentage per thousand of the weight of the mixed slurry, then add fructosyltransferase 1.02‰ with an enzyme activity of 500,000 U / g, glucose oxidase with an enzyme activity of 100,000 U / g 1.24‰ and enzyme activity 30 0.35‰ of glucose isomerase per 10,000 U / g, and hydrolyzed at 45°C for 8 hours to obtain a slurry containing fructooligosaccharides.

[0036] (2) Weigh 150kg of fresh medlar, soak in 150kg of water at 20°C for 1 hour, use a colloid mill to refine the beating, and heat it with a plate heat exchanger to inactivate the enzyme and prevent browning. The enzyme inactivation temperature is 100°C for 5 minutes to obtain wolfberry juice.

[0037] (3) The wolfberry jui...

Embodiment 3

[0042] (1) Weigh 150kg of sun-dried chicory roots, wash them, cut them into sections, add 150kg of water to soak for 6 hours, and after draining, put the wet material under the condition of 1.8Mpa and cook for 30min to obtain chicory root pulp, add 22.5kg of Water to obtain the chicory root slurry, in percent per thousand of the weight of the mixed slurry, then add fructosyltransferase 1.55‰ with an enzyme activity of 500,000 U / g, glucose oxidase with an enzyme activity of 100,000 U / g 1.58‰ and enzyme activity 30 0.51‰ of glucose isomerase per 10,000 U / g, and hydrolyzed at 50°C for 8 hours to obtain a slurry containing fructooligosaccharides.

[0043] (2) Weigh 150kg of fresh medlar, soak in 150kg of water at 25°C for 1 hour, use colloid mill to refine the pulp, and heat it with a plate heat exchanger to inactivate the enzyme and prevent browning. The enzyme inactivation temperature is 95°C for 10 minutes to obtain wolfberry juice.

[0044] (3) The wolfberry juice obtained in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com