Harmless treatment method for waste water-based mud

A technology for harmless treatment and waste water, which is applied in mining wastewater treatment, water/sludge/sewage treatment, sludge treatment, etc. It can solve the problem that waste water-based mud cannot be effectively treated, and achieve the effect of reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The waste drilling mud in the Yonghe block of PetroChina Coalbed Methane Linfen Branch Company was treated. The waste mud index: solid content 11.8%, total hardness 27300mg / L, calcium ion 9000mg / L, iron ion 221mg / L, magnesium ion 921mg / L.

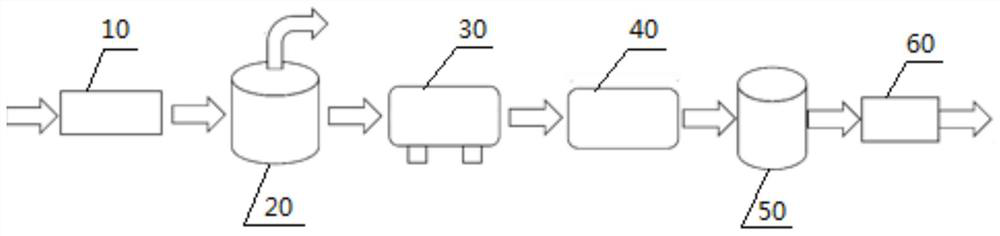

[0039] Processing technology such as figure 1 As shown, the specific process includes: waste drilling mud is pumped into the first tempering tank 10 through a mud pump, inorganic salt and PAM are added in the first tempering tank 10, and the waste drilling mud is broken and tempered; The waste mud after gelatin conditioning is pumped into the plate and frame filter press 20 for solid-liquid separation through the plunger pump. After maintaining the pressure in the plate filter press 20 for 1 hour, the filtrate and filter cake are discharged. After the strength of the filter cake reaches the standard, It can be used to pave the well site road; the filtrate is discharged into the electrocatalytic reaction device 30, and in the electroc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com