Nano-silicon anticorrosive agent for preparing metal working fluid and preparation method of nano-silicon anticorrosive agent

A metalworking fluid and anti-corrosion agent technology, applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve the problems that silicon conformal coatings cannot be stabilized and precipitated, and metalworking fluids cannot be applied, so as to achieve no production hazard and no production Pollution, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

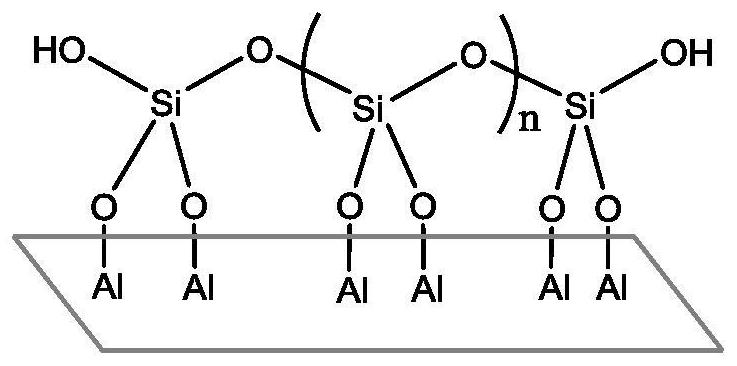

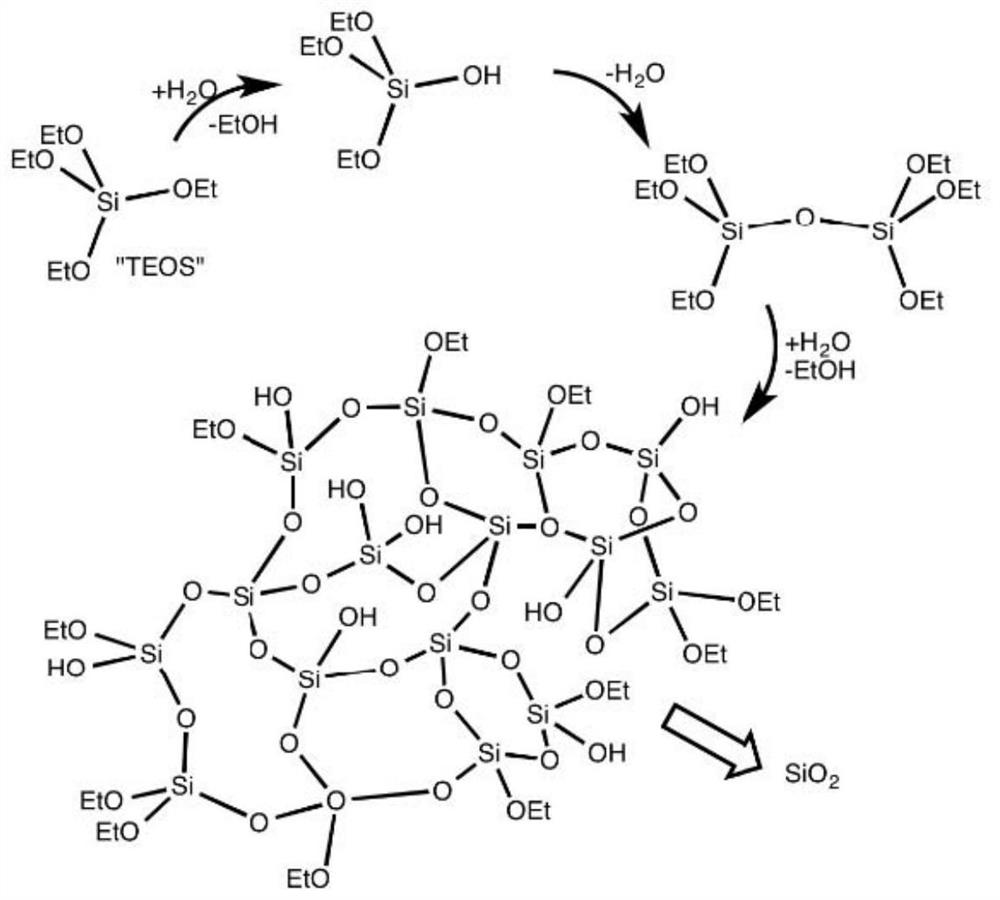

Method used

Image

Examples

preparation example Construction

[0015] A kind of preparation method of the nano-silicon anticorrosion agent that is used to prepare metalworking fluid of the present invention, comprises the following steps:

[0016] Step 1, mixing the organic amine compound with water, set aside;

[0017] Step 2. Add the silane coupling agent dropwise to the system obtained in step 1 under the protection of inert gas and stirring;

[0018] Step 3. After the dropwise addition, warm up to the first temperature, and stir under the protection of inert gas, then heat up to the second temperature, and stir under the protection of inert gas. After the stirring, cool down to obtain clear and transparent nano-silicon corrosive;

[0019] Wherein, the second temperature is higher than the first temperature.

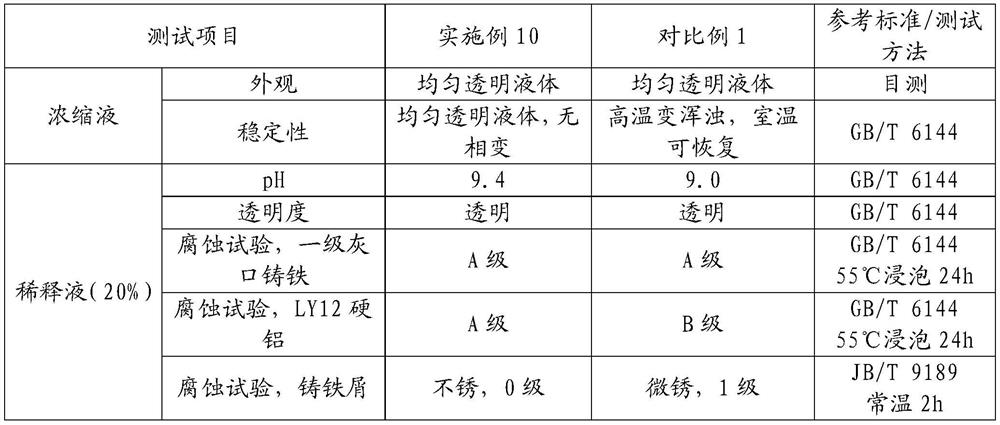

[0020] It can be seen from the above description that the beneficial effect of the present invention is that the nano-silicon antirust agents sold in the metalworking fluid market at this stage are not suitable for adding to th...

Embodiment 1

[0034] A preparation method for preparing a nano-silicon anticorrosion agent for metalworking fluid, specifically comprising the following steps:

[0035] Step 1. Mix 17.9g of aminopropyltrimethoxysilane with 41g of water, and place it in a 250mL double-necked reaction flask with a built-in magnetic stirrer;

[0036] Step 2. Put 31.2g of tetraethoxysilane in a 50mL dropping funnel, then assemble the dropping funnel on the double-mouth reaction flask, and connect the nitrogen protection system to the double-mouth reaction flask;

[0037] Step 3. Slowly add tetraethoxysilane dropwise to the mixture of aminopropyltrimethoxysilane and water under vigorous stirring (constant speed) under the condition of nitrogen gas protection at room temperature, and the dropping time is 60 minutes;

[0038] Step 4. After the dropwise addition, raise the temperature to 60°C and keep it warm, and stir for 120min under the protection of nitrogen, then raise the temperature to 90°C and keep it warm,...

Embodiment 2

[0040] A preparation method for preparing a nano-silicon anticorrosion agent for metalworking fluid, specifically comprising the following steps:

[0041] Step 1, mix 14.6g of triethylenetetramine with 50g of water, and place in a 250mL double-necked reaction flask with a built-in magnetic stirrer;

[0042] Step 2. Put 27g of tetraethoxysilane in a 50mL dropping funnel, then assemble the dropping funnel on the double-mouth reaction flask, and connect the nitrogen protection system to the double-mouth reaction flask;

[0043] Step 3. Slowly add tetraethoxysilane dropwise to the mixture of triethylenetetramine and water under vigorous stirring (constant speed) under the condition of nitrogen gas protection at room temperature, and the dropping time is 50 minutes;

[0044] Step 4. After the dropwise addition, heat up to 45°C and keep warm, and stir for 130min under nitrogen protection, then heat up to 80°C and keep warm, and stir for 130min under nitrogen protection, and cool to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com