Method capable of reducing crystal grain size of aluminum phosphate molecular sieve

A kind of technology of phosphorus-aluminum molecular sieve and molecular sieve, which is applied in the direction of molecular sieve catalyst, molecular sieve characteristic aluminum phosphate, molecular sieve and alkali exchange phosphate, etc. It can solve the problems of unfavorable product actual production and application, complex synthesis process and high cost of raw materials, so as to improve the comprehensive utilization The effect of low rate, type and particle size, simple and practical synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Source or preparation of aluminum phosphate molecular sieve samples (a) to (l) used as seed crystals.

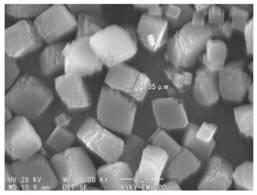

[0035] The sample (a) is the flaky SAPO-34 molecular sieve prepared in Example 6 of patent CN106477595A, with a crystal size of about 1.5 μm and a thickness of 50-200 nm.

[0036] Sample (b) is a SAPO-11 molecular sieve purchased from Shanghai Shentan Environmental Protection New Material Co., Ltd., with a crystal particle size of 1-5 μm.

[0037] sample (c)

[0038] Add 12.3g pseudo-boehmite, 18.5g phosphoric acid, 7.4g silica sol, 26.8g triethylamine and 75g water into the beaker, mix and stir evenly, then transfer to a 200ml hydrothermal synthesis kettle, and heat up to 200°C under stirring Crystallized for 30h. After the crystallization, the solid product was cooled and centrifuged. The solid product was washed with deionized water until neutral, dried at 120°C, and then baked in a muffle furnace at 600°C for 4 hours to obtain a SAPO molecular sieve ...

Embodiment 2~15

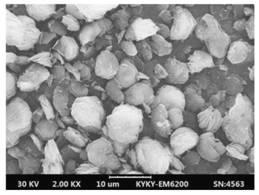

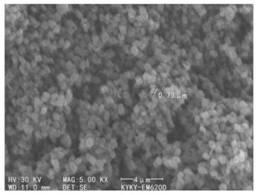

[0057] Embodiment 2~15: the preparation of small particle size aluminum phosphate molecular sieve

[0058] When using silicon source, aluminum source, phosphorus source, aluminum phosphorus molecular sieves (a)~(l) that can be used as seeds, metal salt solution, organic amine template agent R and water or the above preparation (a)~(l) samples The collected mother liquor is mixed with silicon source, aluminum source, phosphorus source, phosphorus-aluminum molecular sieves (a)~(l) that can be used as crystal seeds, metal salt solution, and organic amine template agent R in a certain proportion to prepare crystallization liquid , secondary crystallization at a certain temperature for a period of time; the aluminum phosphate molecular sieve with small particle size is prepared by separation. Among them, the source of the seed crystal used as the raw material and the template used for the secondary crystallization of the traditional / seed crystal method, each raw material, the ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com