Preparation method and application of two-phase synergistic nickel hydroxide electrode material

An electrode material, nickel hydroxide technology, applied in the field of energy storage, can solve problems such as poor cycle stability, and achieve the effects of high specific capacity, low cost, and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2

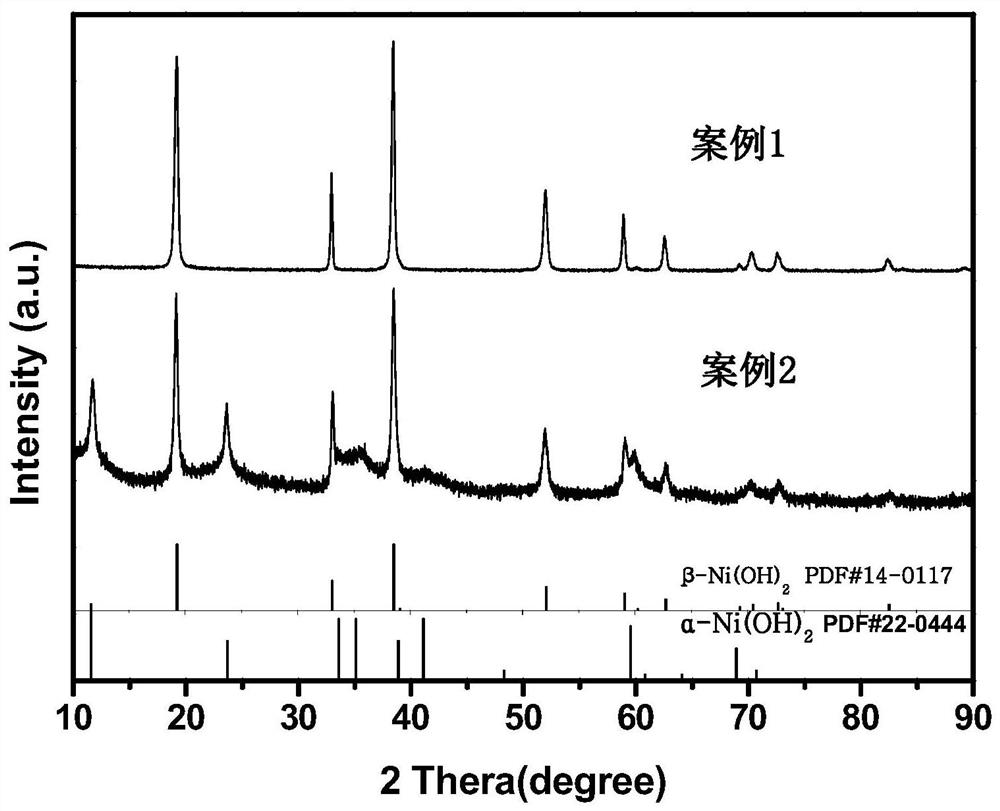

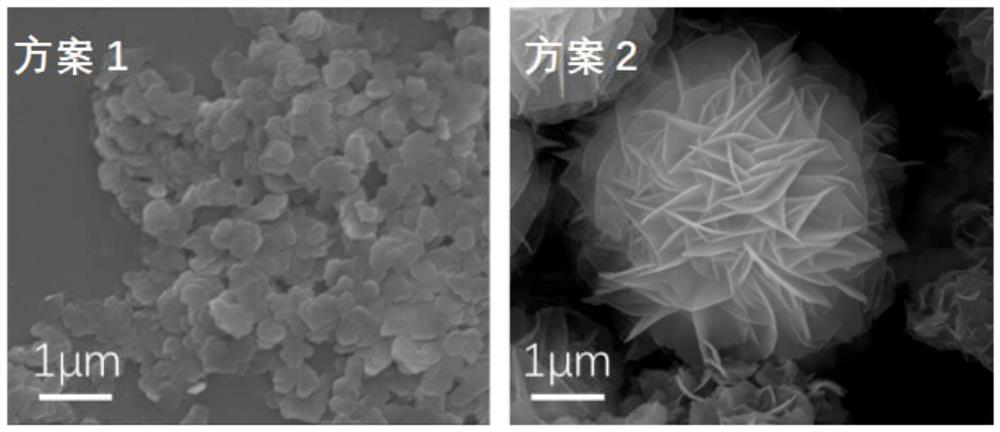

[0025] Examples 1 and 2 prepared Mo-doped nickel hydroxide electrode materials according to the following steps.

[0026] (a) The nickel salt is configured as an aqueous solution of 0.05-0.1mol / L nickel salt; wherein the nickel salt is nickel acetate; the complexing agent is added in an amount of 0-150mg, and the complexing agent is ammonium heptamolybdate.

[0027] (b) After the solid-phase raw materials are completely dissolved, the pH is adjusted to 9 with ammonia water, and the mixed solution is sonicated for 30 min.

[0028] (c) Subsequently, the mixed solution is subjected to hydrothermal treatment at a temperature of 160° C. and a reaction time of 12 hours.

[0029] (d) Finally, a light green precipitate was obtained, which was centrifuged at a centrifugal speed of 4000-8000r / min, the liquid phase was recovered, and the solid phase was washed three times with distilled water and ethanol respectively; dried at 80°C for 12 hours, and then ground to a uniform The nickel h...

Embodiment 1

[0031] (1) configure 0.067mol / L nickel acetate aqueous solution;

[0032] (2) Adjust the pH of the solution to 9 with ammonia water, and sonicate the mixed solution for 30 minutes;

[0033] (3) Put the light green suspension into the reaction kettle, and conduct a hydrothermal reaction at 160°C for 12 hours. After completion, naturally cool to room temperature;

[0034] (4) Obtain light green precipitate, centrifuge, centrifuge speed is 5000-8000r / min, wash 3 times with deionized water and ethanol respectively, dry (drying temperature is 60-100 ℃, drying time 8-16 hours), grind Obtain nickel hydroxide electrode material after being uniform;

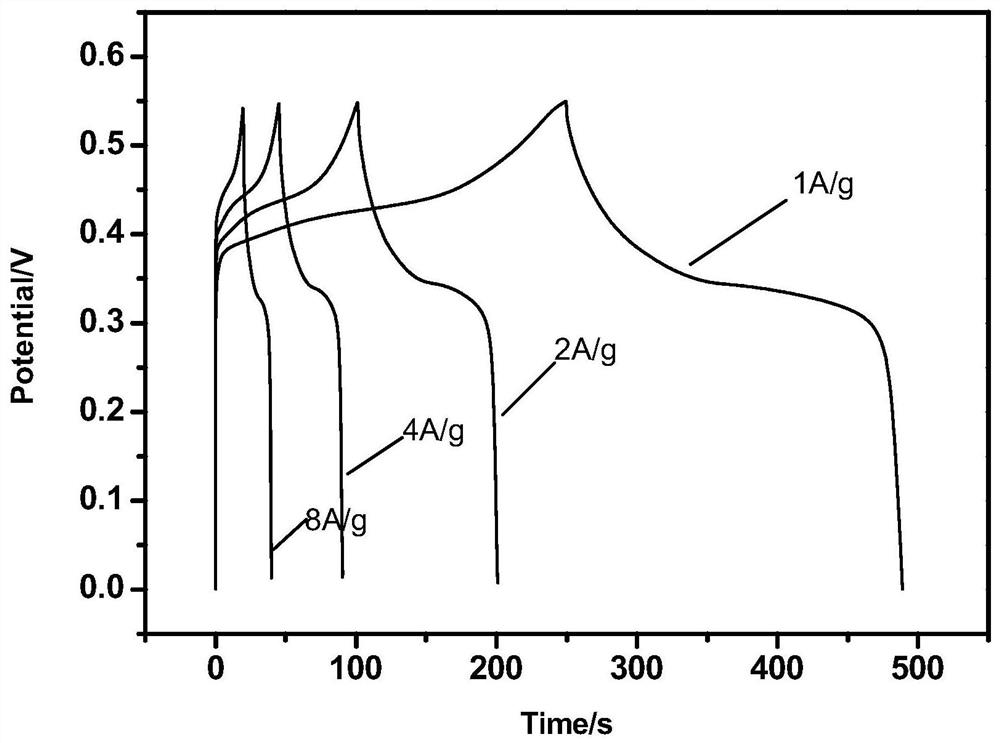

[0035] (5) Evenly mix the prepared nickel hydroxide electrode material with acetylene black and PTFE according to the ratio of 80:10:10 to form a paste, and brush evenly to 1cm with a brush 2 On the nickel foam current collector, dry at 60°C for 8h, and then press it into a sheet under a pressure of 10MPa to prepare the Ni(OH)2 electrod...

Embodiment 2

[0037] (1) Configure 0.067mol / L nickel acetate aqueous solution, add 90mg complexing agent (ammonium molybdate tetrahydrate) under continuous stirring, and stir for 30min to dissolve completely;

[0038] (2) Adjust the pH of the solution to 9 with ammonia water, and sonicate the mixed solution for 30 minutes;

[0039] (3) Put the light green suspension into the reaction kettle, and conduct a hydrothermal reaction at 160°C for 12 hours. After completion, naturally cool to room temperature;

[0040] (4) Obtain light green precipitate, centrifuge, centrifuge speed is 5000-8000r / min, wash 3 times with deionized water and ethanol respectively, dry (drying temperature is 60-100 ℃, drying time 8-16 hours), grind Obtain nickel hydroxide electrode material after being uniform;

[0041] (5) Evenly mix the prepared nickel hydroxide electrode material with acetylene black and PTFE according to the ratio of 80:10:10 to form a paste, and brush evenly to 1cm with a brush 2 On the nickel fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com