Method for extracting vanadium by using ore pulp electrolysis

A technology of slurry electrolysis and anode electrolysis, which is applied in the field of vanadium extraction, and achieves the effects of simple process flow, improved vanadium extraction efficiency and product quality, and low pollution vanadium extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

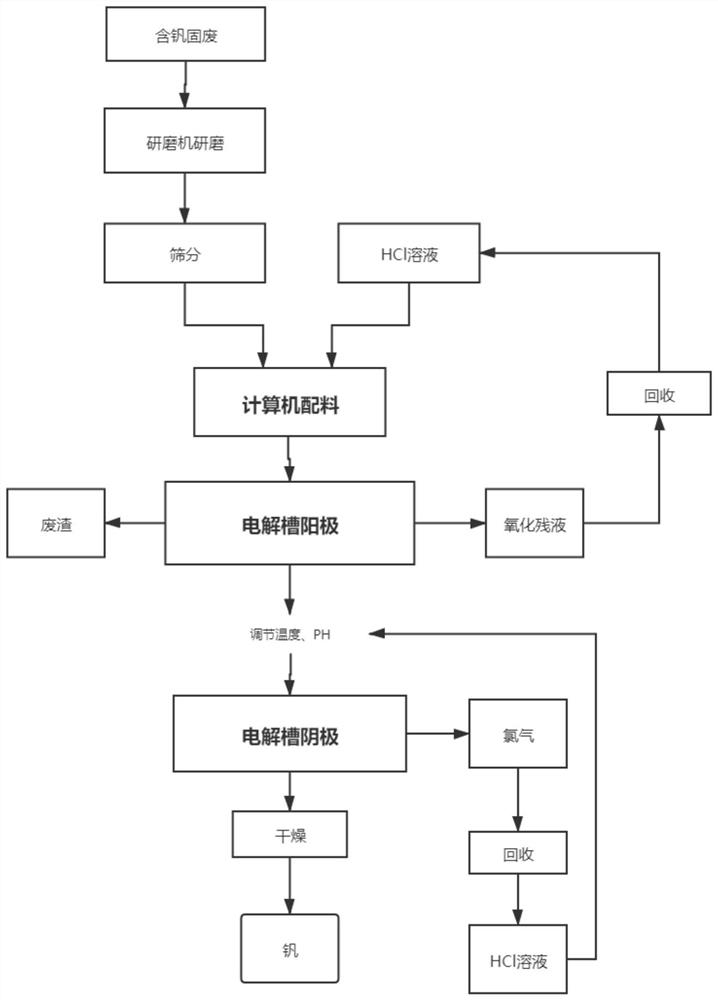

[0038] Such as figure 1 As shown, the pretreatment process is divided into two stages of grinding and screening, and finally the particle size of vanadium-containing solid waste is 0-5mm. The waste vanadium catalyst obtained by pretreatment contains vanadium solid waste, the main component is V 2 o 5 The percentage content is 5.2%, Na 2 SO 4 The percentage content is 68.0%, (NH 4 ) 2 SO 4 The percentage content is 20.2%, NH 4 The percentage content of Cl is 3.2% and the concentration is 0.4mol / L HCl solution is mixed according to the mass ratio of 1:6, and then sent to the anode of the electrolytic cell. The separator used is a nafion film, and the electrodes of the cathode and anode are graphite. The electrolyte is NaCl, adjust the temperature of the electrolytic cell to 40°C, start the agitator in the anode electrolytic cell, control the rotation speed at 220r / min, and power on for electrolysis. During the electrolysis process, add HCl solution to the cathode, adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com