Integrated method for dry desulfurization and denitrification and cementing material manufacturing

A gelling material and dry desulfurization technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high cost and expensive, and achieve the effects of low cost, high denitrification efficiency and desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0077] According to one embodiment of the present invention, the cementitious material is composed of the following raw materials in parts by weight: 25-55 parts by weight of the first ash, 15-55 parts by weight of fly ash, and 15-45 parts by weight of mineral powder and alkali activator are 4-8 parts by weight. According to another embodiment of the present invention, the cementitious material is composed of the following raw materials in parts by weight: 30-50 parts by weight of the first ash, 20-50 parts by weight of fly ash, and 20-45 parts by weight of mineral powder and alkali activator are 5-7 parts by weight. According to yet another embodiment of the present invention, the cementitious material is composed of the following raw materials in parts by weight: 35-45 parts by weight of the first ash, 25-45 parts by weight of fly ash, and 20-40 parts by weight of mineral powder parts and alkali activator are 5-6 parts by weight.

[0078] Before mixing the raw materials in...

Embodiment 1

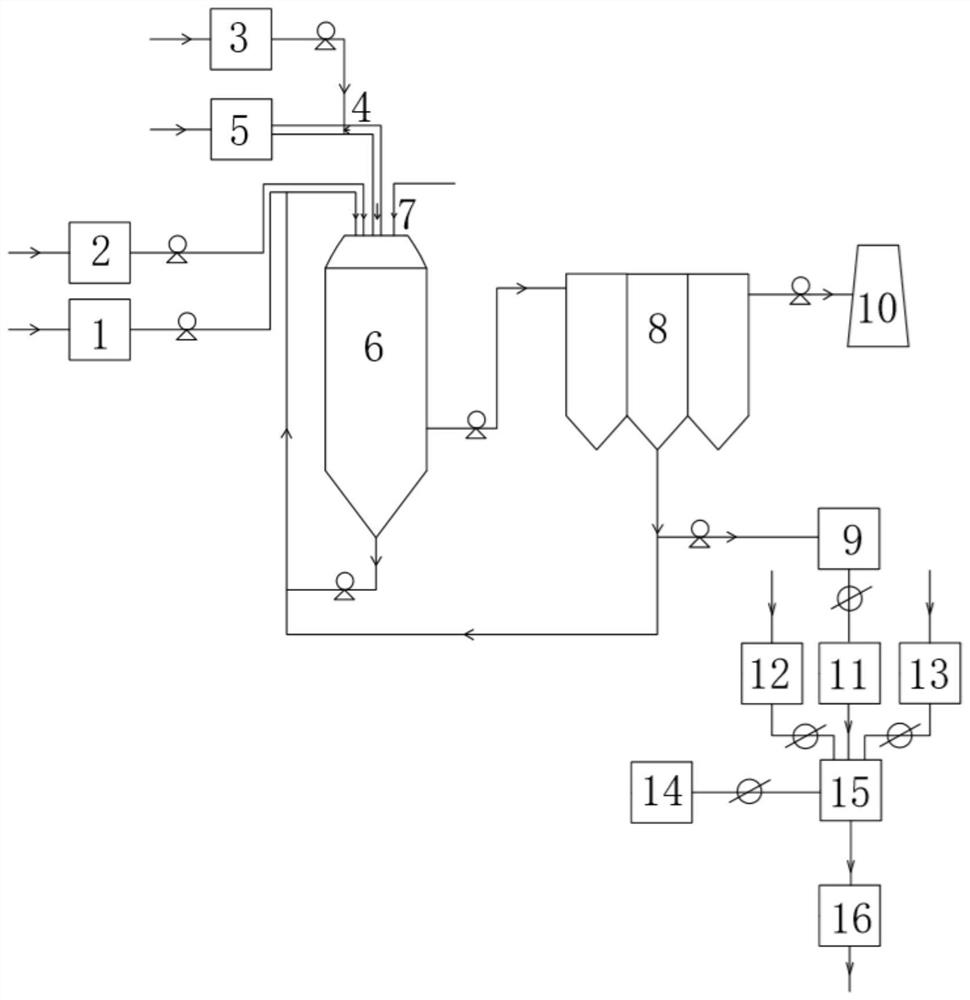

[0084] The schematic diagram of the device used for the integrated method of dry desulfurization and denitrification and cementitious material production of the present invention is as follows figure 1 shown. Use the electrostatic precipitator 5 to remove particulate matter from the raw flue gas from the sintering machine to obtain dust-removed flue gas. Pass the dedusting flue gas into the flue gas duct. Aqueous hydrogen peroxide solution (concentration is 27.5wt%) is supplied to the atomizer 4 that is positioned at the flue gas pipeline by aqueous hydrogen peroxide supply device 3; Then aqueous hydrogen peroxide is sprayed to flue gas pipeline by atomizer 4 Inside, it contacts and reacts with the dedusting flue gas in the flue gas pipe to form oxidized flue gas.

[0085] Pass the oxidized flue gas into the dense phase dry tower 6, and simultaneously spray the calcium hydroxide dry powder and the ammonium bisulfite dry powder into the dense phase dry tower 6 through the abs...

Embodiment 2

[0099] The difference from Example 1 is only that the raw material composition ratio of the gelling material is different. Refer to Table 5 for the dosage of each raw material of the gelling material in this embodiment. The properties of the obtained gelled material are shown in Table 6.

[0100] Table 5, the amount of each raw material of the cementitious material

[0101] parameter value unit first ash 45 parts by weight fly ash 35 parts by weight mineral powder 20 parts by weight Alkali activator (NaOH) 5 parts by weight

[0102] Table 6. Properties of cementitious materials

[0103] age Compressive strength Flexural strength unit 3d 33 4.7 MPa 7d 39 6.9 MPa 28d 73 11.1 MPa

[0104] It can be seen from the table that the flexural strength and compressive strength of the obtained cementitious material can reach the relevant national standard of 52.5 grade cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com