Method for passivating sulfurized hydrogenation catalyst

A hydrogenation catalyst and passivation treatment technology, which is applied in the direction of physical/chemical process catalysts, catalyst protection, chemical instruments and methods, etc., can solve the problems of large dosage and high cost of liquid passivation agents, and achieve simple operation and save start-up time , to avoid the effect of spontaneous response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

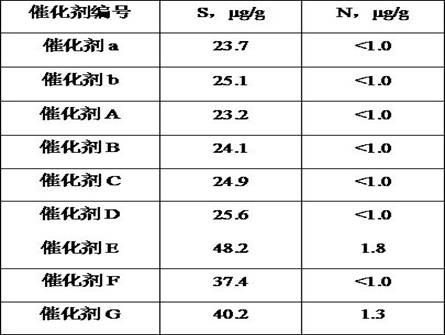

Examples

Embodiment 1

[0023] Take the industrially produced hydrogenation catalyst and put it into the reactor, raise the pressure to 3.0MPa after airtightness is qualified, raise the temperature to 150°C at a rate of 30°C / h, introduce sulfurized oil, the sulfurized oil is catalytic gasoline, and use CS 2 As a vulcanizing agent, the content of the vulcanizing agent in the vulcanized oil is 2wt%, the distillation range ranges from 40 to 200°C, continue to heat up to 230°C, keep the temperature constant for 3 hours, then raise the temperature to 350°C, and keep the temperature constant for 3 hours to obtain the hydrogenation catalyst a in a sulfided state.

[0024] The sulfided hydrogenation catalyst a is sprayed and soaked in dodecene under the protection of nitrogen, the amount of dodecene is 30% (V) of the catalyst, the temperature is raised to 150°C, and nitrogen is purged, and the flow rate of nitrogen is 50L / h. After purging for 5 hours, cool down to room temperature, vacuumize the container con...

Embodiment 2

[0026] Under the protection of nitrogen, unsaturated impregnate anthraquinone ethanol solution with sulfided catalyst a, wherein the amount of anthraquinone is 50% (V) of the catalyst, anthraquinone: ethanol = 1:1, heat up to 80°C, blow with nitrogen Sweeping, the flow rate of nitrogen gas is 80L / h, after purging for 8h, cool down to 20°C, vacuumize the container containing the catalyst, the vacuum degree is -0.07MPa, then slowly lower the temperature to -20°C, introduce ozone-containing gas (containing The ozone gas is nitrogen with an ozone content of 3%), the gas pressure is 2.0MPa, the flow rate is 20L, and the gas is kept for 0.2h to obtain the finished catalyst B. After replacement with nitrogen gas, the catalyst B is taken out for use.

Embodiment 3

[0028] Take the industrially produced catalyst and put it into the reactor, raise the pressure to 7.0MPa after the airtightness is qualified, and replace it with hydrogen containing hydrogen sulfide gas. state catalyst b.

[0029] Put the catalyst b into the quinoline solution for 30 minutes and immerse it, drain it, and then heat-treat it under nitrogen for 2 hours at a treatment temperature of 100°C. Afterwards, the container containing the catalyst is evacuated to a vacuum degree of -0.1MPa, cooled to 0°C, and ozone-containing gas (ozone-containing gas is nitrogen with an ozone content of 1%) is introduced, the gas pressure is 2.0MPa, the flow rate is 6L, and the temperature is maintained at 0.5 h, the finished catalyst C is obtained, and the catalyst is taken out for use after replacing with nitrogen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com