A kind of preparation method of high cationic starch flocculant

A cationic degree and flocculant technology, which is applied in the field of flocculant preparation, can solve the problems of difficult degradation of polyacrylamide, uneven heat release, high transportation costs, etc., and achieve the effects of controllable reaction temperature, suppression of overheating, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

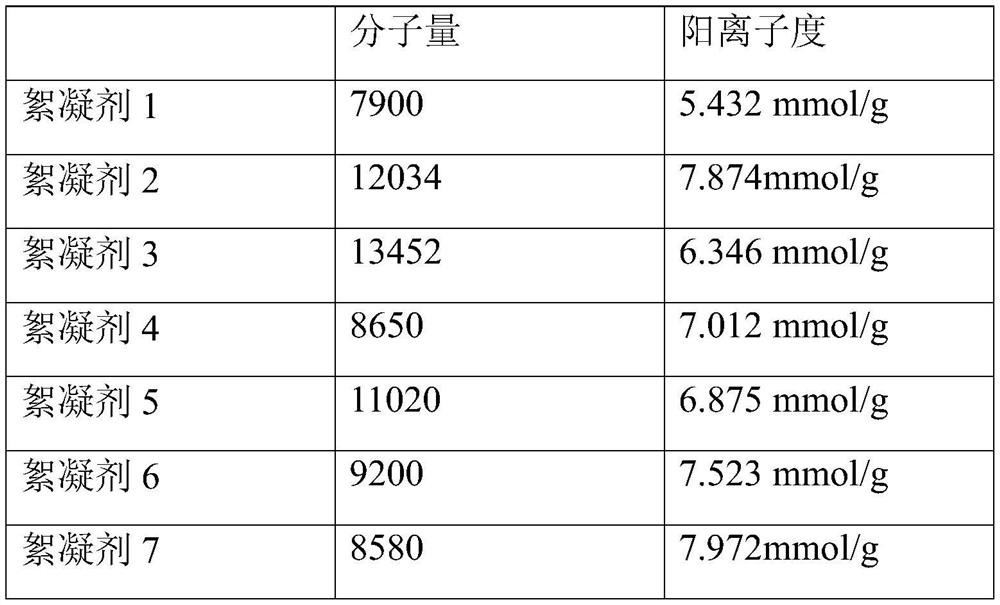

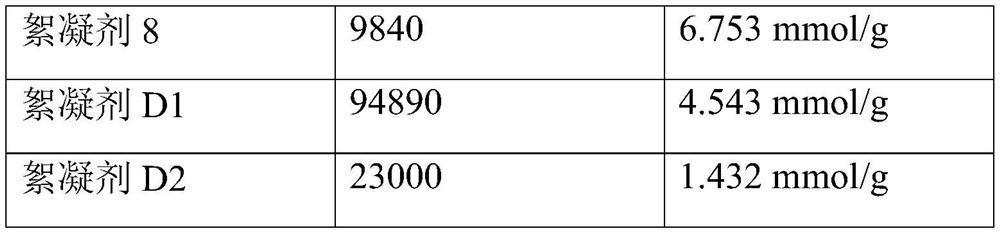

Embodiment 1

[0030] 20g cornstarch, 240g absolute ethanol, 0.5g sodium hydroxide aqueous solution with a concentration of 5mol / g were respectively added to the there-necked flask, stirred for 30min at 60°C, and then 30g of tetraethylenepentamine was added to continue stirring at this temperature. 2h. Subsequently, the temperature was raised to 85° C., 20 g of epichlorohydrin was added dropwise, and the reaction was carried out for 3 h. Finally, 25 g of hydrochloric acid with a concentration of 36% was added, and the mixture was stirred at 50° C. for 1 h to obtain flocculant 1. The properties of the flocculant are shown in Table 1.

Embodiment 2

[0032] 30g corn starch, 250g absolute ethanol, 0.5g potassium hydroxide aqueous solution with a concentration of 5mol / g were respectively added to the three-necked flask, stirred at 50°C for 30min, then added 30g triethylenetetramine and continued to stir at 65°C 2h. Subsequently, the temperature was raised to 80° C., 25 g of epichlorohydrin was added dropwise, and the reaction was carried out for 4 h. Finally, 10 g of sulfuric acid with a concentration of 98% was added, and the mixture was stirred at 50° C. for 50 min to obtain flocculant 2. The properties of the flocculant are shown in Table 1.

Embodiment 3

[0034] 25g of wheat starch, 200g of absolute ethanol, and 0.3g of sodium hydroxide aqueous solution with a concentration of 5mol / g were respectively added to the three-necked flask, stirred at 40°C for 15min, and then added 20g of diethylenetriamine and continued at 60°C. Stir for 1 h. Subsequently, the temperature was raised to 88° C., 27 g of epichlorohydrin was added dropwise, and the reaction was carried out for 3 h. Finally, 5 g of glacial acetic acid with a concentration of 99% was added, and the mixture was stirred at 40° C. for 30 minutes to obtain flocculant 3. The properties of the flocculant are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com