High-temperature-resistant pH-responsive wetting agent as well as preparation and application methods thereof

An application method and a responsive technology, applied in the field of drilling fluid, can solve problems such as not being able to meet the preparation requirements of reversible emulsified drilling fluid, and achieve the effects of improving suspension stability, good rheology, and low fluid loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Typical embodiment 1: The preparation method of a kind of anti-high temperature pH response type wetting agent mentioned in the present invention, comprises the following steps:

[0054] Add 20g of dodecane chloride, 30g of isopropanol, and 10g of ethanol into the reaction kettle, heat it to 85°C under stirring conditions, slowly drop in 11g of tetramethylethylenediamine, and add 200g of dimethyl Amine solution (40%), 40g sodium hydroxide, raise the temperature to 95°C, after 10 hours of reaction, lower the temperature to 55°C, add 2g of ethylenediaminetetraacetic acid, 3g of 30% hydrogen peroxide solution, and react for 4h. After the reaction, add hydrochloric acid to adjust the pH value of the solution to 7-8, add chloroform to extract, and finally recrystallize with acetone to obtain the product, which is the high-temperature resistant pH-responsive wetting agent mentioned in the present invention, and the substitution number is SLRSJ-1.

[0055] The present inventi...

Embodiment 2

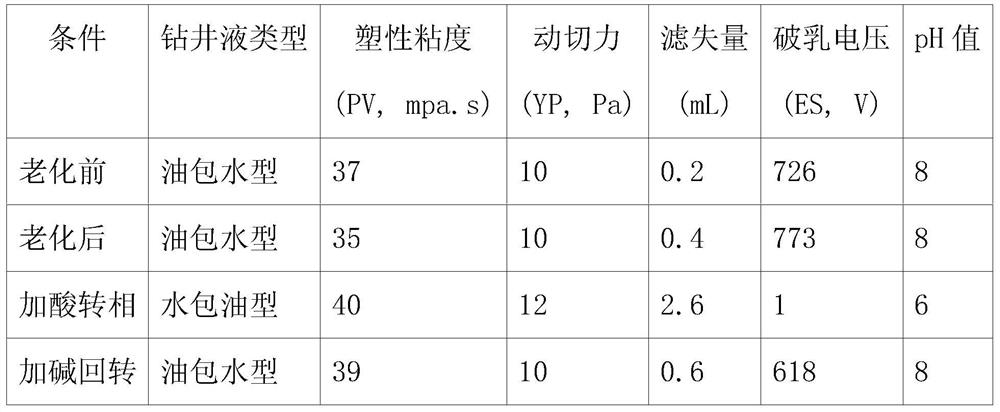

[0057] Add 50g of diesel oil, 4g of reversible emulsifier, and 30g of 20% calcium chloride aqueous solution to the high-speed mixer in turn, heat the water bath to 50°C, stir the high-speed mixer at 5000 rpm for 40 minutes, and then add organic soil in turn 1.5g, pH responsive wetting agent (SLRSJ-1) 1.0g, oil-based fluid loss reducer 3g, calcium oxide 0.5g and barite, the addition of barite makes the density of reversible emulsified drilling fluid up to 2.5 g / cm 3 and continue stirring for 60 minutes to obtain the high-density reversible emulsified drilling fluid.

Embodiment 3

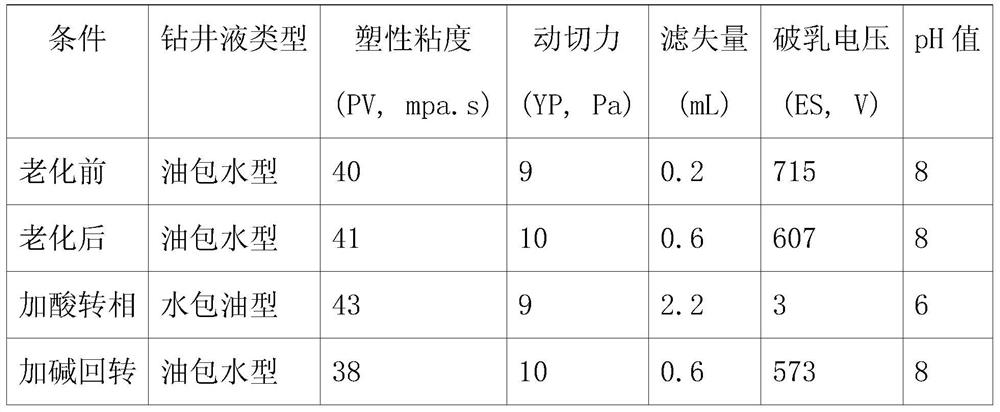

[0059] Add 50g of white oil, 4g of reversible emulsifier, 30g of 20% calcium chloride aqueous solution to the high-speed mixer in turn, heat the water bath to 50°C, stir the high-speed mixer at 5000 rpm for 40 minutes, and then add organic Soil 1.5g, pH responsive wetting agent (SLRSJ-1) 1.0g, oil-based fluid loss reducer 3g, calcium oxide 0.5g and barite, the addition of barite makes the density of the reversible emulsified drilling fluid the highest 2.5g / cm 3 and continue stirring for 60 minutes to obtain the high-density reversible emulsified drilling fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com